A magnetic levitation pump with three degrees of freedom magnetic bearing

A technology of magnetic bearings and degrees of freedom, applied in the direction of bearings, bearing cooling, shafts and bearings, etc., can solve the problems of complex mathematical models of levitation force and driving force, increase the difficulty of control, etc., and achieve long-term stable use and precision The effect of simple control and rotor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

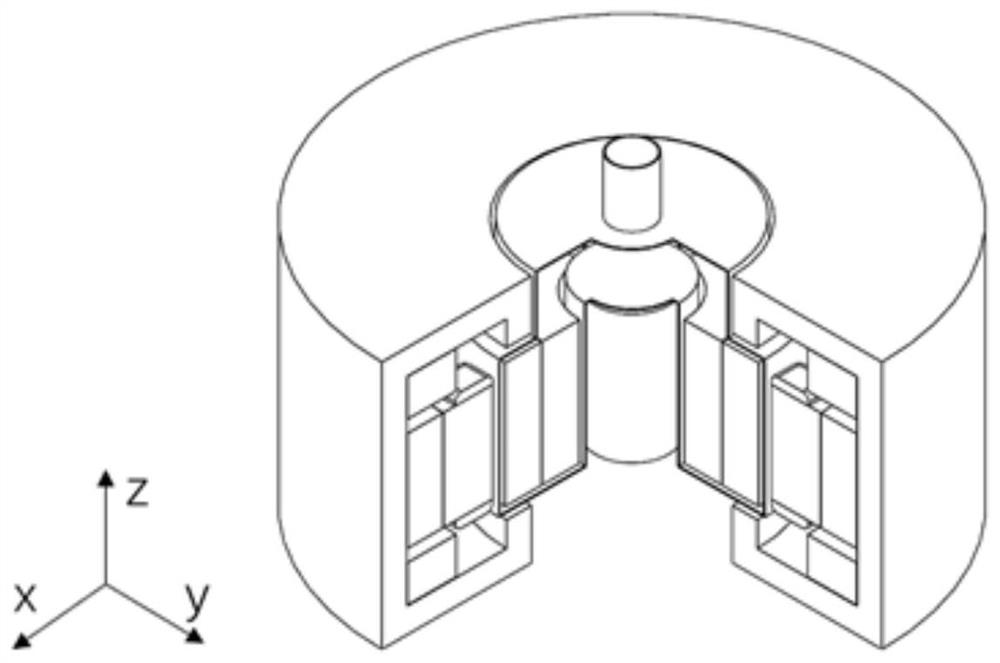

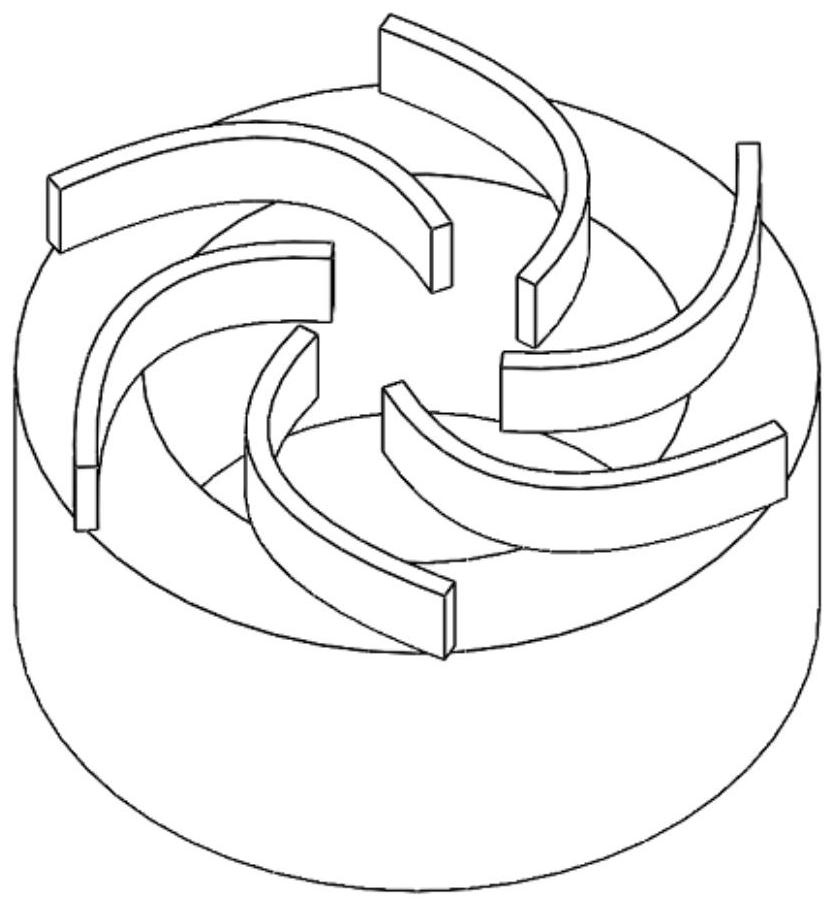

[0027] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a magnetic levitation pump related to the present invention includes a pump head PH, a three-degree-of-freedom magnetic bearing MB and a rotary drive assembly MT.

[0028] The pump head PH is composed of the cavity formed by the pump cover 1A and the pump casing 1B and its contents; the rotor 20 is arranged in the pump head PH, and the rotor 20 includes the impeller 2, the annular rotor core 8 and the rotor permanent magnet 9, the impeller 2 It is used to drive the water to rotate so that it is pumped to the outside of the pump due to centrifugal force. The arrangement of the impeller 2 can refer to the existing centrifugal pump scheme, and the arrangement of the ring-shaped rotor core 8 and the rotor permanent magnet 9 can refer to the rotary drive assembly MT below. Description: The pump head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com