Surface treatment method for dental implant

A dental implant and surface treatment technology, applied in the field of dental implant surface treatment, can solve the problems of easy damage, loss of protection, etc., and achieve the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The surface treatment method of the dental implant of the present embodiment comprises the following steps:

[0039] (1) Pretreatment: Polish the titanium-based implant to be treated until its surface is smooth and ready for use;

[0040] (2) pickling treatment: the titanium-based implant pretreated in step (1) is placed in an acid solution for pickling, and is set aside;

[0041] (3) Drying treatment: the titanium-based implant after the pickling treatment in step (2) is cleaned and then dried for use;

[0042] (4) Surface anodic oxidation pretreatment: place the titanium-based implant after the drying treatment in step (3) in the surface anodic oxidation electrolyte for surface anodic oxidation, and set aside;

[0043] (5) Surface micro-arc oxidation treatment: place the titanium-based implant after the surface anodic oxidation pretreatment in step (4) in the surface micro-arc oxidation electrolyte for surface micro-arc oxidation, and set aside;

[0044] (6) Finished ...

Embodiment 2

[0100] The implants prepared by the surface treatment method of dental implants in Example 1 and the implants prepared in Comparative Examples 1-4 were respectively selected for testing (BIC and ITBC values), and the results are shown in Table 4.

[0101] Table 4 comparison of test parameters

[0102]

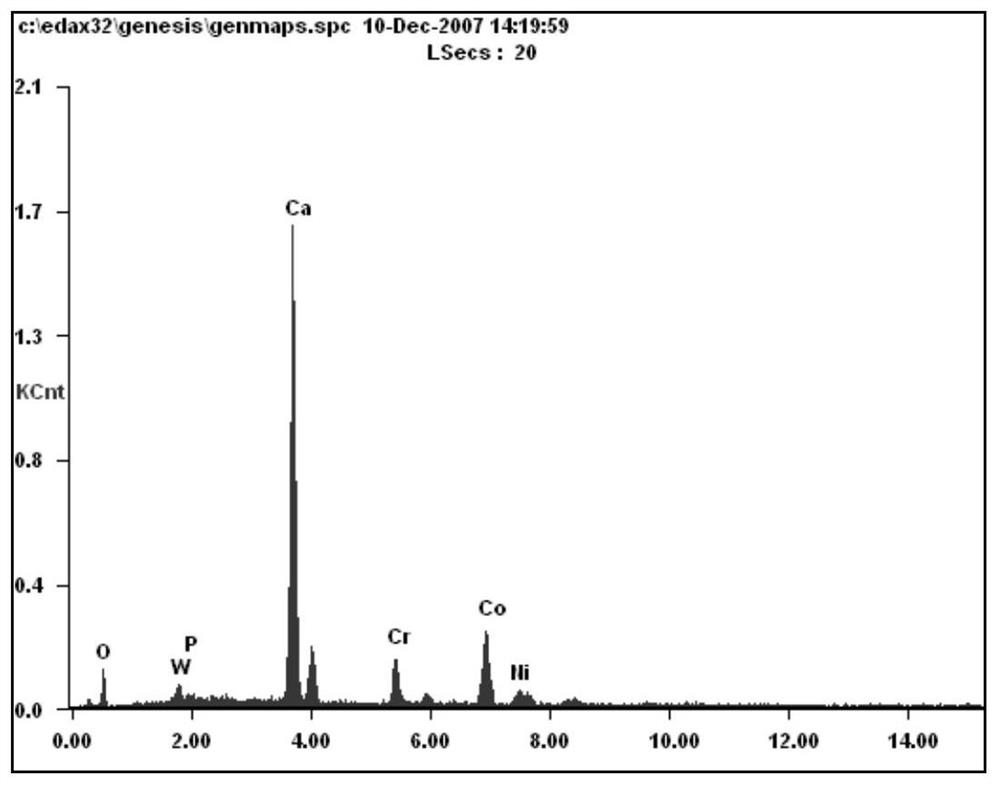

[0103] combine figure 1 , figure 2 , Table 4, it can be seen that compared with Comparative Examples 1-4, the surface shape of the implant prepared by the present invention is more suitable for the attachment of bone cells, and it can be seen that the implant prepared by the present invention shows the highest cell adhesion. In addition, as a result of histological examination and analysis, it was observed that the implant prepared by the present invention has more mature bone formation. It can be seen that the implant prepared by the present invention is an excellent biocompatible titanium-based implant.

[0104] In summary, the dental implant surface treatment method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com