Equipment and process for nano-composite electroplating on the inner surface of metal pipe fittings

A metal pipe fitting and nano-composite technology, applied in electrolytic components, electrolytic processes, electrolytic coatings, etc., can solve the problems of limited ability to break aggregates, prone to agglomeration, organic pollution of plating solution, etc. The effect of good plating uniformity and good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The implementation of the present invention is illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

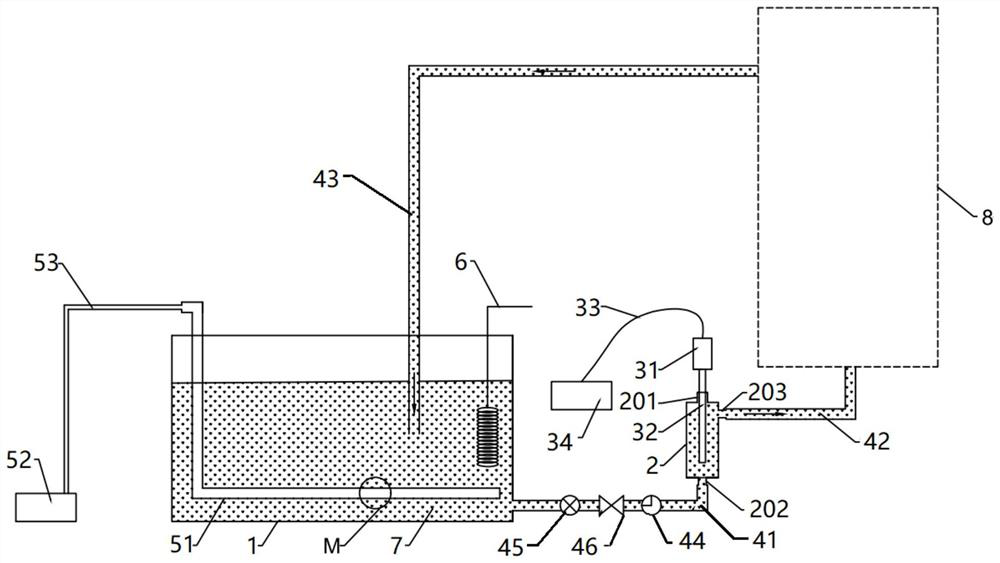

[0048] see in conjunction Figure 1 to Figure 5 , a device for nanocomposite electroplating on the inner surface of metal pipe fittings, comprising:

[0049] A plating solution tank 1 containing a plating solution 7 containing nanoparticles;

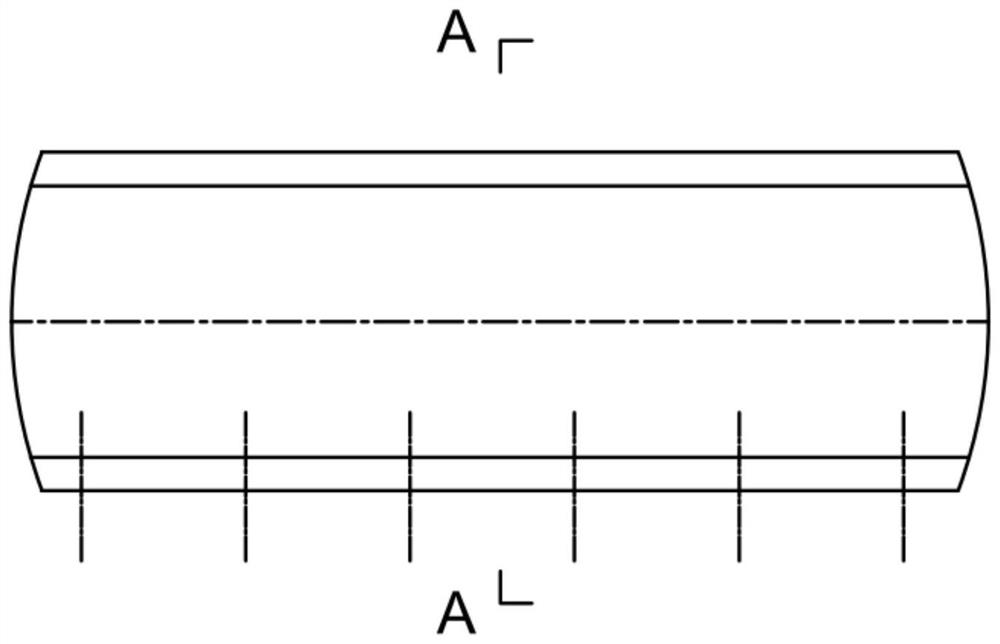

[0050]The fluid plating assembly 8 outside the tank, the fluid plating assembly outside the tank includes a metal pipe fitting 81 used as a cathode and an anode post 82 positioned in the metal pipe fitting 81, the inner wall of the metal pipe fitting 81 and the outer wall of the anode post 82 Surrounded by an annular column cavity 801;

[0051] A crushing kettle 2, the crushing kettle 2 is arranged outside the plating solution tank 1;

[0052] Concentrated-energy ultrasonic crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com