Combined growth system with multiple epitaxial reaction chambers, operation method, equipment, manufactured chip and application thereof

An operation method and reaction chamber technology, applied in semiconductor/solid-state device manufacturing, coating, gaseous chemical plating, etc., can solve the problems of increased time cost, non-compliance, capacity matching, etc., to reduce equipment and time, design Reasonable and convenient, with wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

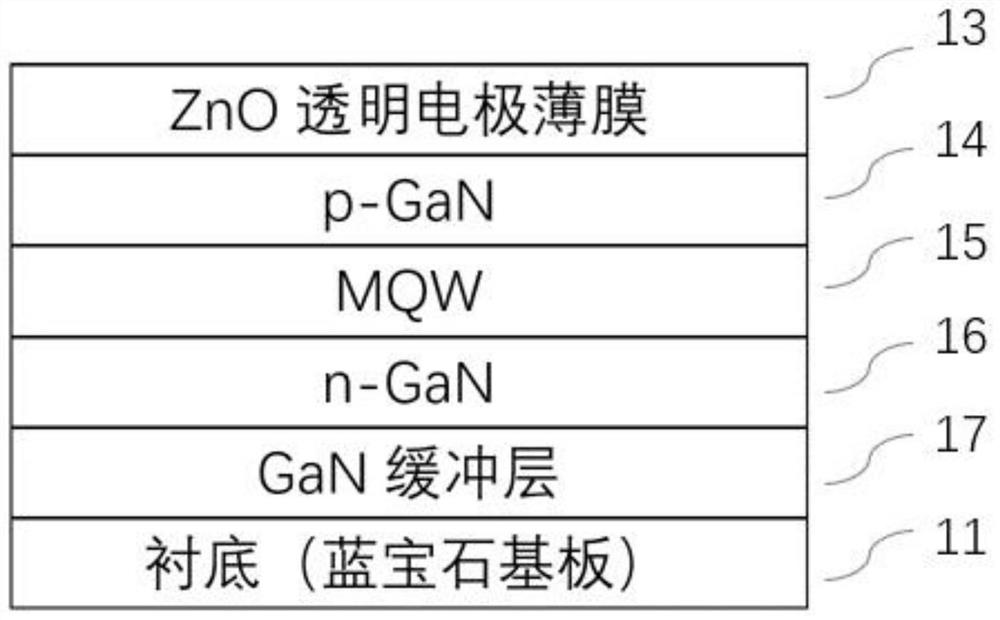

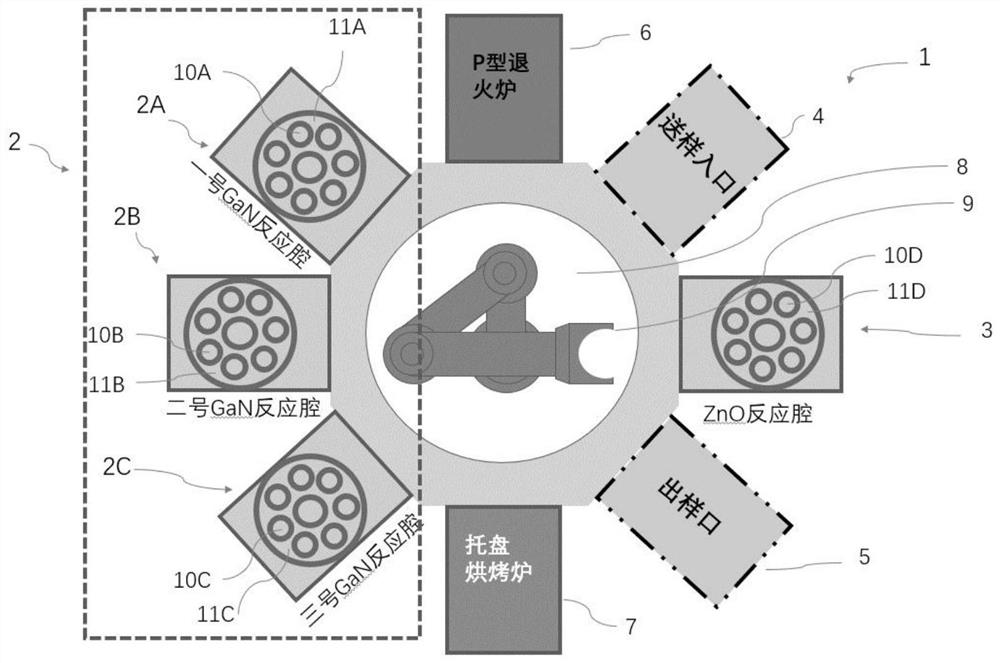

[0057] The first MOCVD machine for producing GaN epitaxial wafers and the second MOCVD machine for producing ZnO thin films are used, and the growth time of GaN epitaxial growth is set to 6h, and the growth time of ZnO thin film is set to 2.5h (=preheating time length 0.5h+actual The growth time is 2h), then the number of GaN reaction chambers is 6 / 2.5=2.4, take 3, and the number of ZnO reaction chambers is 1, connected to production, such as figure 2 shown.

[0058] The epitaxial joint growth process of this embodiment is:

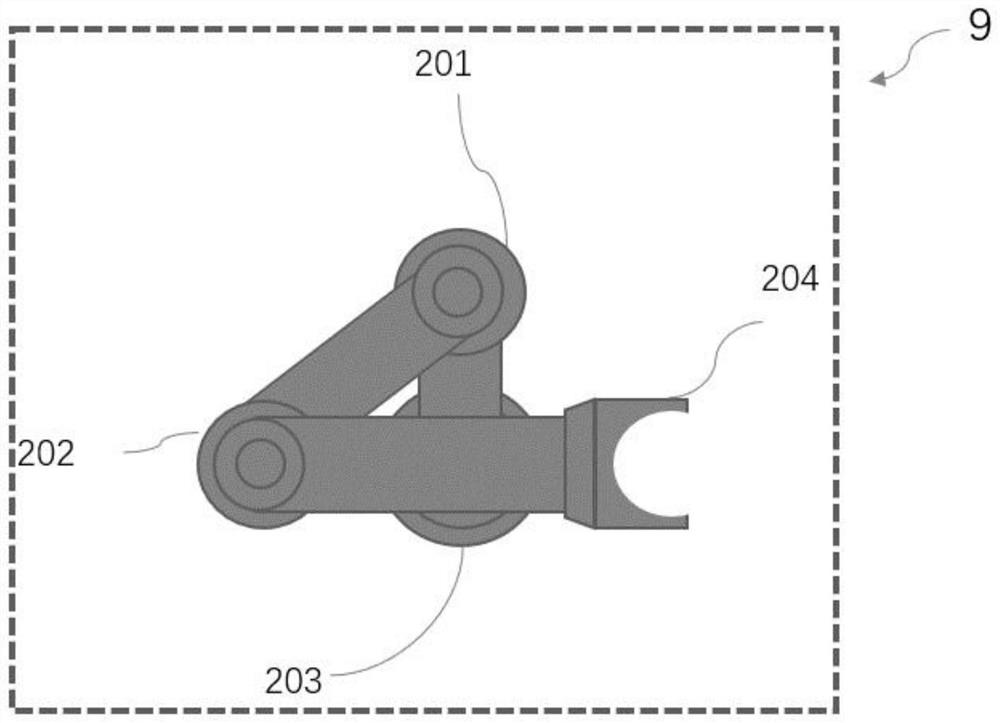

[0059] 1) Put the graphite disk 11 with the substrate 10 into the sample delivery inlet 4, close the external entrance of the sample delivery inlet 4, open the interface with the transfer box 8, and the transmission arm 9 sends the graphite disk 11 with the substrate 10 to the The transmission box 8, the interface between the sample delivery inlet 4 and the transmission box 8 is closed, the transmission box 8 starts to extract air to create a vacuum env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com