Low-foam easy-to-rinse laundry detergent containing enzyme preparation and preparation method thereof

A laundry liquid and easy-rinsing technology, which is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of fat salt precipitation, easy stratification, and poor low-temperature stability of saturated fatty acid salts, etc. Achieve the effects of strong detergency, improved easy-to-bleach, and good detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

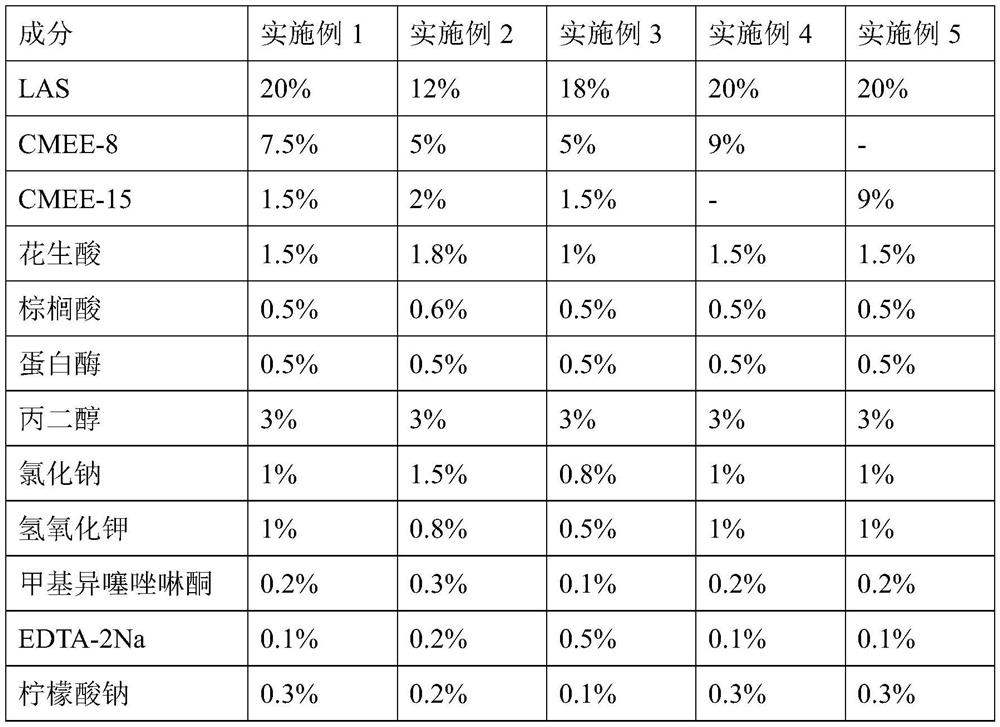

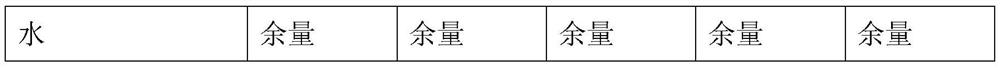

Embodiment 1~5

[0028] Embodiment 1-5 Preparation method of low-foaming easy-rinsing type laundry detergent:

[0029] A) Take the deionized water of the formula and add it into the stirring pot, heat it to 50-60°C, add potassium hydroxide; stir evenly, add saturated fatty acid, and stir until dissolved;

[0030] B) Continue to add LAS and methyl cocoate ethoxylate in turn, stir until dissolved, add sodium citrate to adjust the pH of the material; cool down to 40-45°C, add sodium chloride, protease, propylene glycol and methylisothiazoline Ketone and EDTA-2Na, stir evenly, and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com