Nano engine oil additive and preparation method thereof

An additive and nanotechnology, applied in the fields of additives, petroleum industry, lubricating compositions, etc., can solve the problems of increasing the in-situ warm-up time, affecting the service life of the car, endangering the health of the car, etc., to reduce the friction coefficient, reduce emissions, and avoid injuries. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

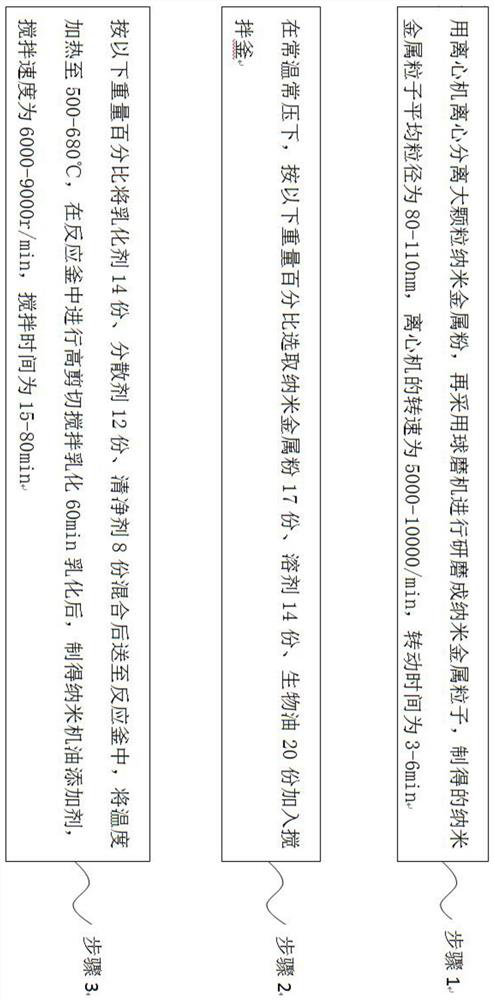

[0045] (1) the preparation method of nano machine oil additive of the present invention, comprises the following steps:

[0046] a) centrifuge to separate the large-particle nano-metal powder first, and then use a ball mill to grind into nano-metal particles. The average particle diameter of the prepared nano-metal particles is 80nm. The rotating speed of the centrifuge is 5000 / min, and the rotation time is 6min;

[0047] b) Mix 17 parts of nano-metal powder, 13 parts of solvent, 19 parts of bio-oil, 13 parts of emulsifier, 11 parts of dispersant, and 7 parts of detergent according to the weight ratio, and stir at 5000r / min for 40min to obtain Nano oil additive.

[0048] c) directly adding the above prepared nano engine oil additive to the automobile engine according to 0.1% of the weight ratio of the nano engine oil additive.

Embodiment 2

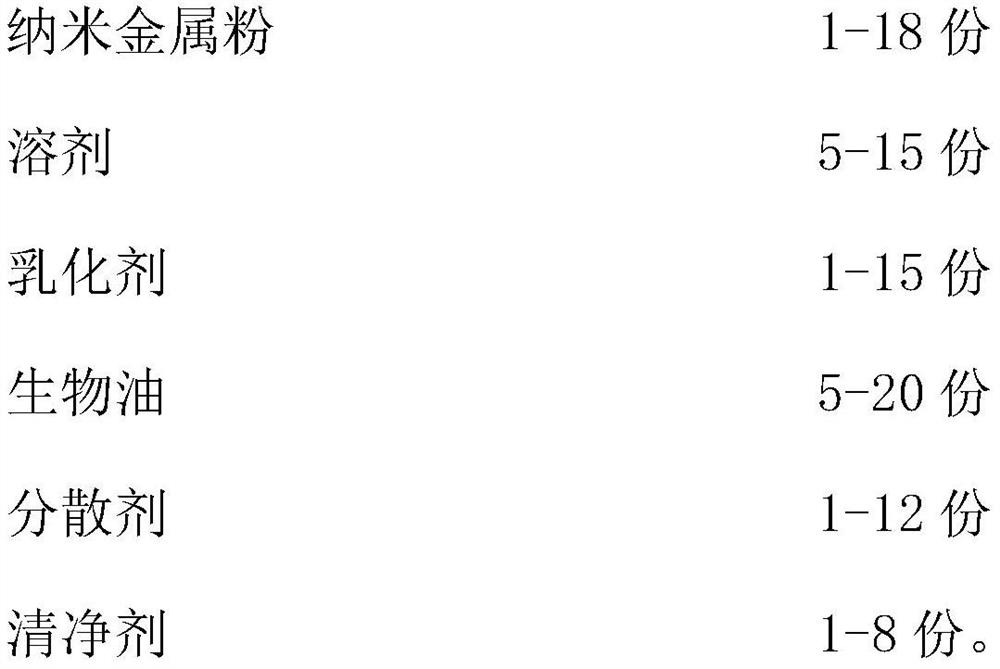

[0050] (1) the preparation method of nano machine oil additive of the present invention, comprises the following steps:

[0051] a) Use a centrifuge to centrifugally separate the large-particle nano-metal powder, and then use a ball mill to grind it into nano-metal particles. The average particle size of the prepared nano-metal particles is 90nm. The speed of the centrifuge is 5000 / min, and the rotation time is 6min.

[0052] b) Mix 16 parts of nano-metal powder, 12 parts of solvent, 18 parts of bio-oil, 12 parts of emulsifier, 10 parts of dispersant, and 6 parts of detergent according to the weight ratio, and stir at 6000r / min for 35min to obtain Nano oil additive.

[0053] c) directly adding the above prepared nano engine oil additive to the automobile engine according to 0.1% of the weight ratio of the nano engine oil additive.

Embodiment 3

[0055] (1) the preparation method of nano machine oil additive of the present invention, comprises the following steps:

[0056] a) centrifuge to separate the large-particle nano-metal powder first, and then use a ball mill to grind into nano-metal particles. The average particle diameter of the prepared nano-metal particles is 80nm. The rotating speed of the centrifuge is 7000 / min, and the rotation time is 2min;

[0057] b) Mix 15 parts of nano-metal powder, 11 parts of solvent, 18 parts of bio-oil, 12 parts of emulsifier, 10 parts of dispersant, and 6 parts of detergent according to the weight ratio, and stir at 8000r / min for 30min to obtain Nano oil additive.

[0058] c) directly adding the above prepared nano engine oil additive to the automobile engine according to 0.1% of the weight ratio of the nano engine oil additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com