SBS modified asphalt stabilizer and SBS modified asphalt

A technology of modified asphalt and stabilizer, applied in the field of SBS modified asphalt stabilizer and SBS modified asphalt, can solve the problems of low production efficiency, long product development time, low asphalt ductility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

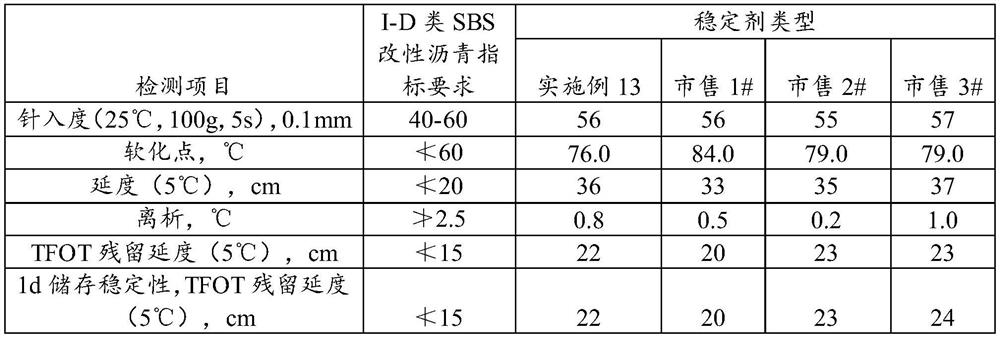

Examples

Embodiment 1

[0051] The base asphalt (Haiyun No. 70 asphalt) was heated to 170°C, aromatic oil and YH-791HSBS were added, and the shearing machine was used for high-speed shearing at a speed of 4000rpm for 30min, then the compound stabilizer was added, and the mixture was stirred at 300rpm for 4h.

Embodiment 2

[0053] Heat the base asphalt (Haiyun No. 70 asphalt) to 170°C, add three-line reduced wax oil, YH-791HSBS, use a shearing machine, shear at a high speed of 4000rpm for 30min, then add the compound stabilizer, stir at 300rpm for 4h .

Embodiment 3

[0055] The base asphalt (Haiyun No. 70 asphalt) was heated to 170°C, aromatic oil and 4303SBS were added, and the shearing machine was used for high-speed shearing at 4000rpm for 30min, then the compound stabilizer was added, and the mixture was stirred at 300rpm for 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com