High-performance facing mortar and preparation method thereof

A decorative mortar, high-performance technology, applied in the field of building materials, can solve problems such as affecting the aesthetics and durability of decoration, poor wall bonding strength, affecting production efficiency, etc., to speed up the cement hydration process, flame retardancy Good, improve the effect of early and long-term flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

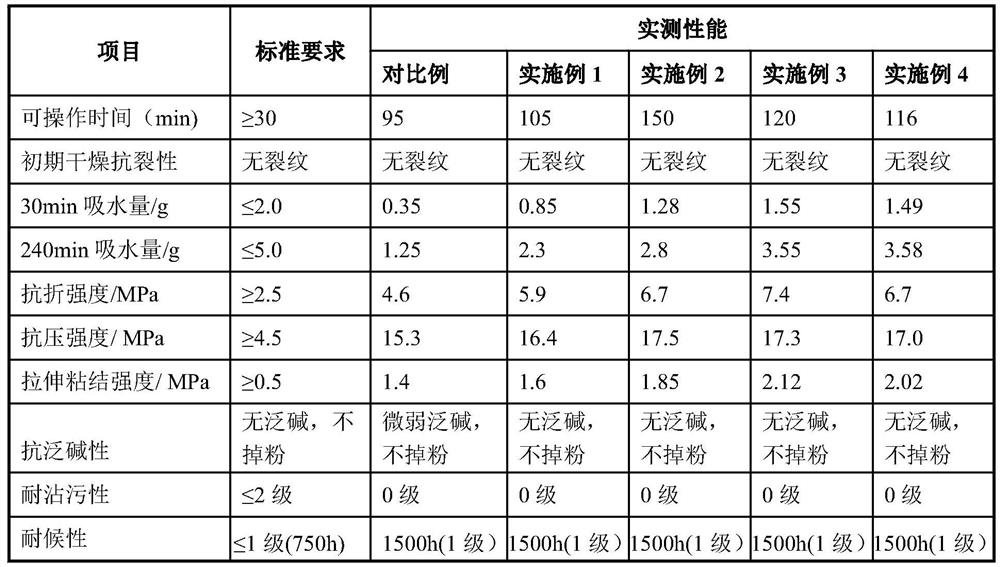

Examples

preparation example Construction

[0050] The preparation method of high-performance facing mortar comprises the following steps:

[0051] Step 1, weighing various raw materials according to weight ratio.

[0052] Step 2: Add the weighed white Portland cement, sulphoaluminate cement, superfine gypsum powder, calcium sulfate whiskers, slag micropowder and high-activity metakaolin into the mixer and mix for 1min-2min.

[0053] Step 3, add the weighed styrene-acrylic emulsion, terpene emulsion, air-entraining agent, defoamer, wetting agent, water-repellent agent, leveling agent and inorganic pigment into the mixer and continue mixing for 2min-3min.

[0054] Step 4, add the weighed quartz sand into the mixer and mix for 2min-3min, then slowly add 20%-25% of the water of the total weight of the high-performance finishing mortar, stir well and then use it.

Embodiment 1

[0057] A high-performance finishing mortar, according to 100 parts of white Portland cement, 28 parts of sulphoaluminate cement, 13 parts of superfine gypsum powder, 5 parts of calcium sulfate whiskers, 25 parts of slag micropowder, and 7 parts of high-activity metakaolin , 3 parts of modified styrene-acrylic emulsion, 5 parts of terpene emulsion, 0.2 part of sodium laurate sulfate air-entraining agent, 0.4 part of polydimethylsiloxane defoamer, 1 part of hydrazide wetting agent, polysiloxane It is prepared by weight ratio of 1 part of water-repellent agent, 1 part of polysiloxane-ether copolymer leveling agent, 5 parts of nano-iron oxide red, and 400 parts of quartz sand.

[0058] First add white Portland cement, sulphoaluminate cement, superfine gypsum powder, calcium sulfate whiskers, slag micropowder and high-activity metakaolin into the mixer and mix for 2 minutes; then add styrene-acrylic emulsion, terpene emulsion, lauric acid base Add sodium sulfate air-entraining agen...

Embodiment 2

[0061] A high-performance finishing mortar, according to 100 parts of white Portland cement, 28 parts of sulphoaluminate cement, 15 parts of superfine gypsum powder, 5 parts of calcium sulfate whiskers, 22 parts of slag micropowder, and 8 parts of high-activity metakaolin , 1 part of modified styrene-acrylic emulsion, 7 parts of terpene emulsion, 0.2 part of sodium laurate sulfate air-entraining agent, 0.4 part of polydimethylsiloxane defoamer, 1 part of hydrazide wetting agent, polysiloxane It is prepared by weight ratio of 1 part of water-repellent agent, 1 part of polysiloxane-ether copolymer leveling agent, 5 parts of nano-iron oxide red, and 400 parts of quartz sand.

[0062] First add white Portland cement, sulphoaluminate cement, superfine gypsum powder, calcium sulfate whiskers, slag micropowder and high-activity metakaolin into the mixer and mix for 2 minutes; then add styrene-acrylic emulsion, terpene emulsion, lauric acid base Add sodium sulfate air-entraining agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com