Preparation method of metal and high polymer material composite 3D printing wire

A polymer material and printing wire technology, applied in the field of metal manufacturing, can solve the problems of poor toughness of metal 3D printing wire, and achieve the effect of good breaking strength and good elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

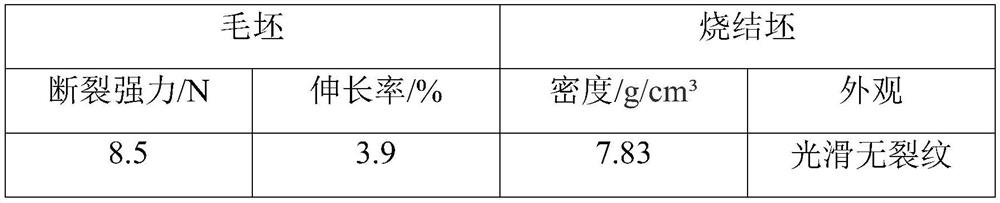

Embodiment 1

[0035] A method for preparing metal and polymer material composite 3D printing wire, comprising the following steps:

[0036] (1) Add 800g of 316L stainless steel powder with a particle size of 400 mesh and 100g of polypropylene into an internal mixer and mix until the stress is stable, the reaction temperature is 185°C, and the rotation speed is 150r / min;

[0037] (2) 50g paraffin, 15g stearic acid are added in the banbury mixer successively, mix to obtain banbury material;

[0038] (3) extrude the banburying material prepared in step (2) through a single-screw extruder to wind up the 3D printing filament, the extrusion temperature is 190°C, and the rotation speed is 400r / min;

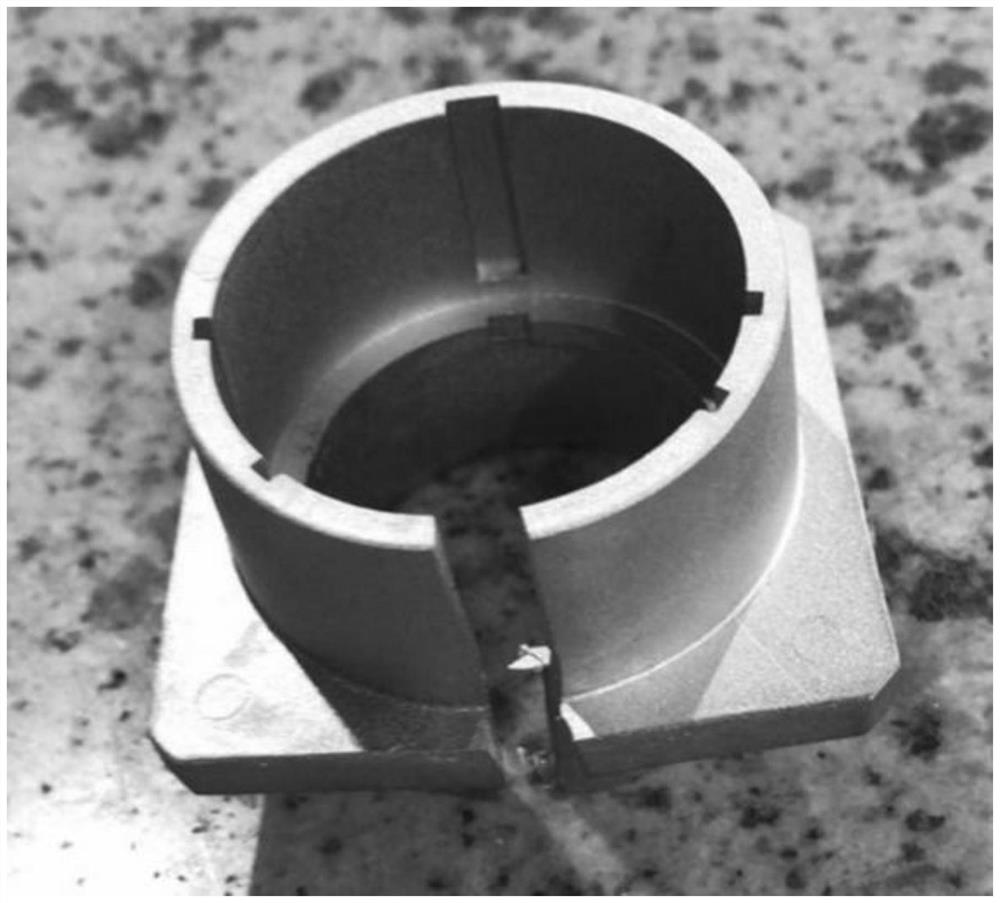

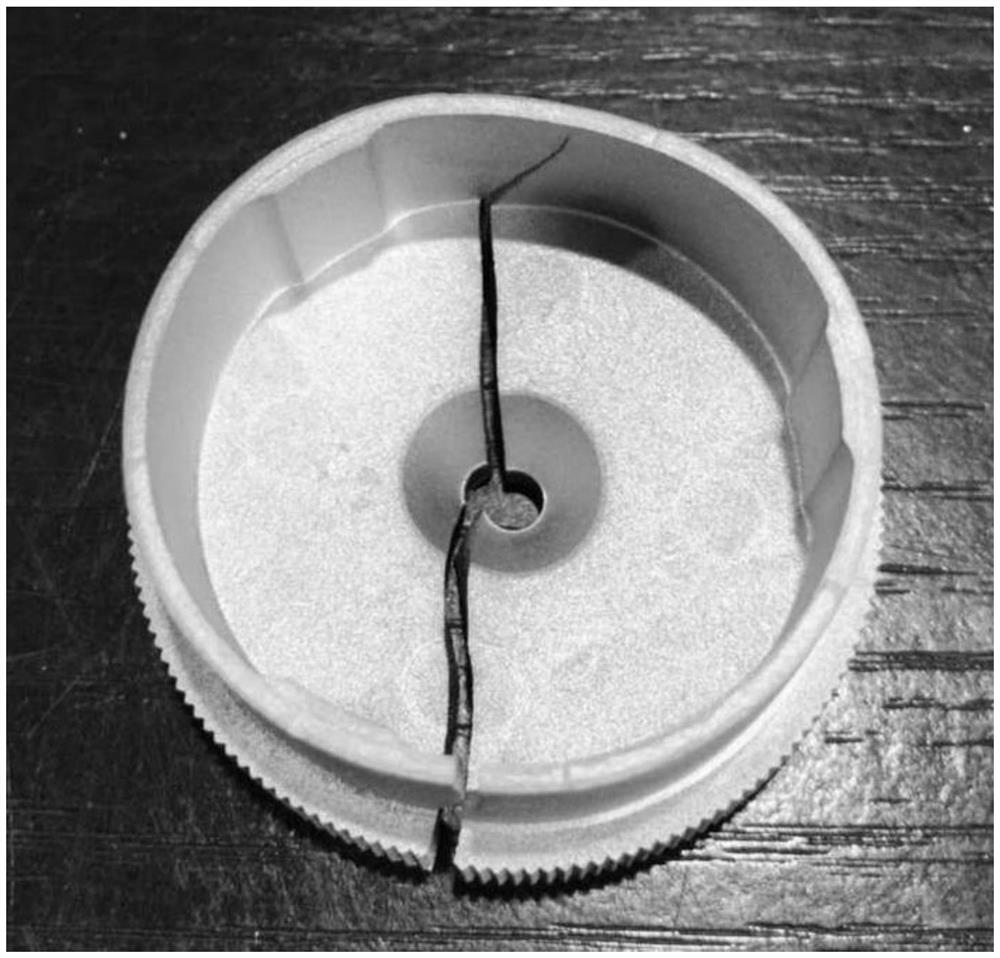

[0039] (4) Extrude the metal printing wire through a melting 3D printing equipment, the printing temperature is 200°C, and the printing speed is 100%, and the blank is obtained;

[0040] (5) Put the blank prepared in step (4) into an oven, raise the temperature to 400°C at a rate of 0.5°C / min, and ke...

Embodiment 2

[0047] A method for preparing metal and polymer material composite 3D printing wire, comprising the following steps:

[0048] (1) Add 800g of 316L stainless steel powder with a particle size of 400 mesh and 140g of polypropylene into the internal mixer and mix until the stress is stable, the reaction temperature is 190°C, and the rotation speed is 200r / min;

[0049] (2) 50g paraffin, 15g stearic acid are added in the banbury mixer successively, mix to obtain banbury material;

[0050] (3) extrude the banburying material prepared in step (2) through a single-screw extruder to wind up the 3D printing filament, the extrusion temperature is 190°C, and the rotation speed is 400r / min;

[0051] (4) Extrude the metal printing wire through a melting 3D printing equipment, the printing temperature is 200°C, and the printing speed is 100%, and the blank is obtained;

[0052] (5) Put the blank prepared in step (4) into an oven, raise the temperature to 400°C at a rate of 0.5°C / min, keep ...

Embodiment 3

[0059] A method for preparing metal and polymer material composite 3D printing wire, comprising the following steps:

[0060] (1) Add 800g of 316L stainless steel powder with a particle size of 400 mesh and 100g of polypropylene into the internal mixer and mix until the stress is stable, the reaction temperature is 190°C, and the rotation speed is 200r / min;

[0061] (2) 80g paraffin, 15g stearic acid are added in the banbury mixer successively, mix to obtain banbury material;

[0062] (3) extrude the banburying material prepared in step (2) through a single-screw extruder to wind up the 3D printing filament, the extrusion temperature is 190°C, and the rotation speed is 400r / min;

[0063] (4) Extrude the metal printing wire through a melting 3D printing equipment, the printing temperature is 200°C, and the printing speed is 100%, and the blank is obtained;

[0064] (5) Put the blank prepared in step (4) into an oven, raise the temperature to 400°C at a rate of 0.5°C / min, and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com