AOI tracing system

A tracking system and data technology, applied in database management systems, special data processing applications, instruments, etc., to achieve the effect of reducing bad risk batches and reducing heavy work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

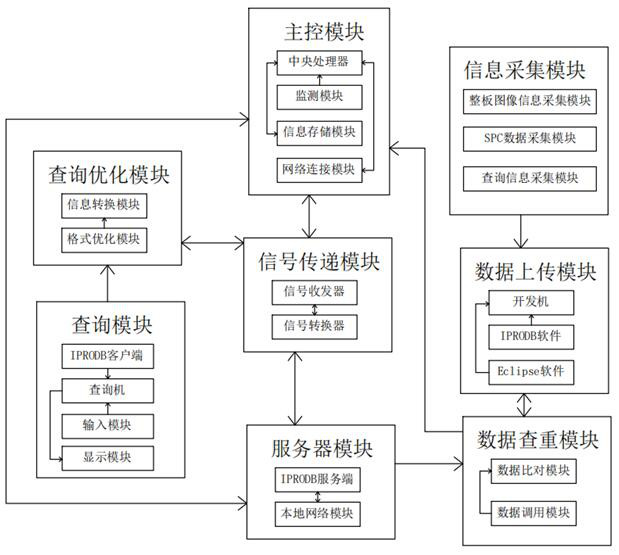

[0048] see figure 1 , the present invention provides a technical solution: AOI traceability system, including a main control module, an information collection module, a data upload module, a data duplicate checking module, a server module, a query module, a query optimization module and a signal transmission module, the main control module and the signal transmission module The transmission module is interactively connected, the query optimization module is interactively connected with the signal transmission module, the server module is interactively connected with the signal transmission module, the information collection module is connected with the data upload module, the data upload module is interactively connected with the data duplicate checking module, and the data duplicate checking module is connected with the main The control module is connected, the query module is connected with the query optimization module, and the main control module is interactively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com