Rigid auxiliary system for concrete uniaxial compression test

An auxiliary system, uniaxial compression technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve problems such as insufficient applicability, achieve strong applicability, simple operation, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The present invention will be further described below in conjunction with the drawings and specific embodiments.

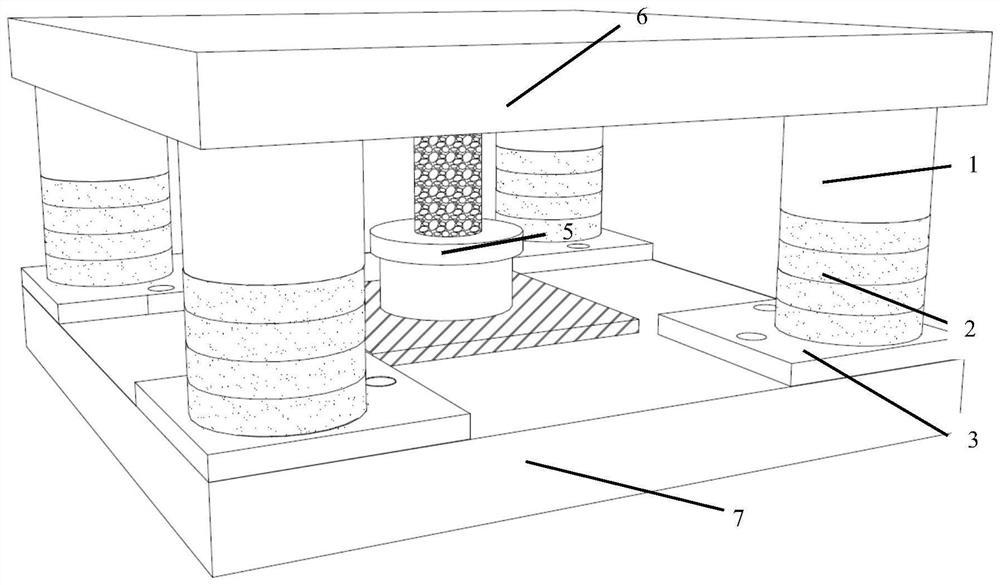

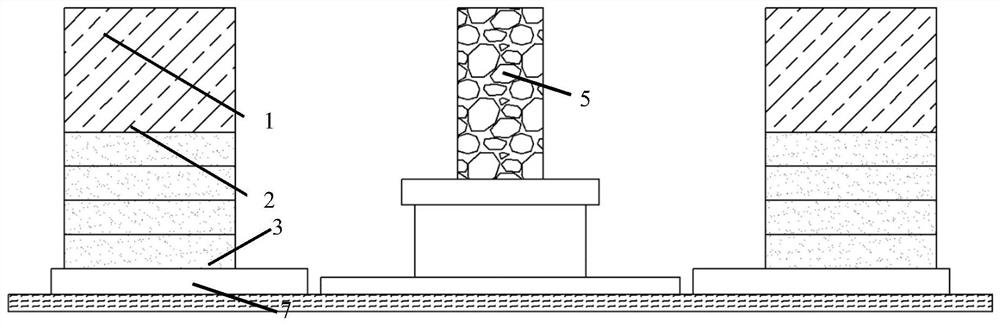

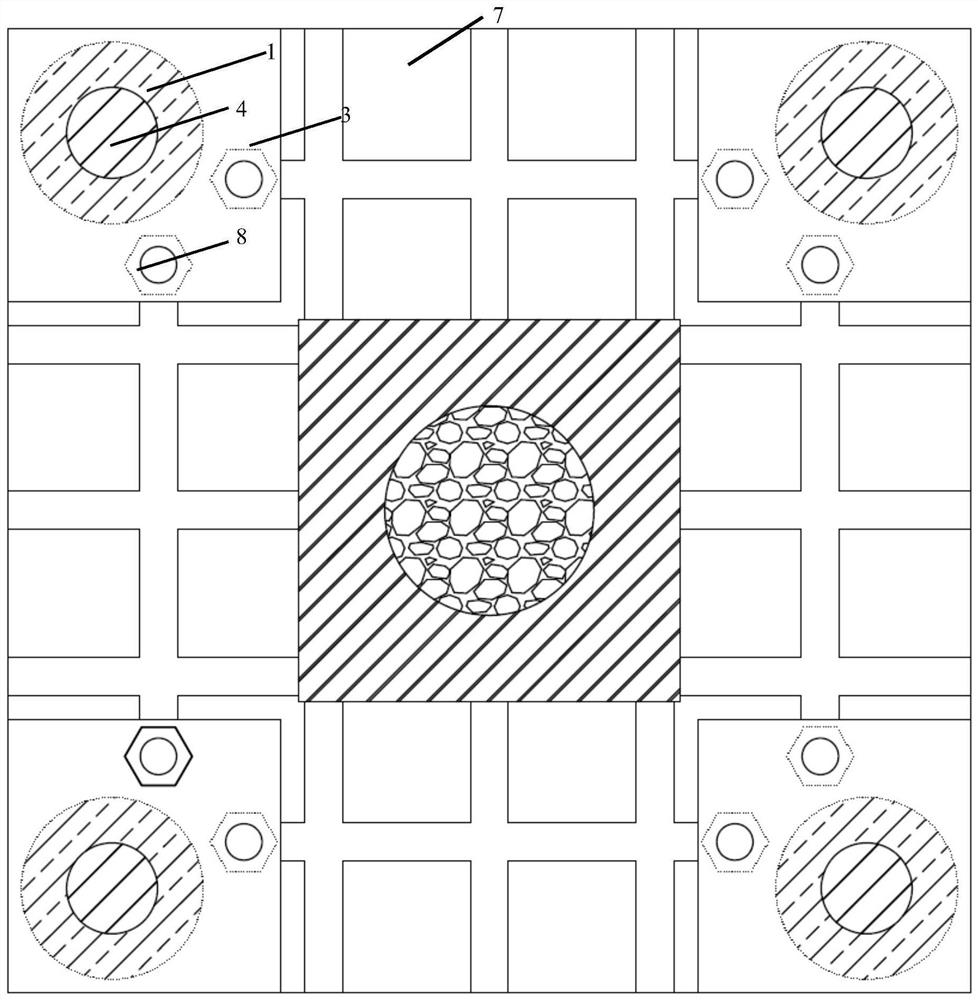

[0017]Such asFigure 1-5Shown: A rigid auxiliary system for uniaxial compression test of concrete, including four rigid auxiliary devices, four sets of rigid auxiliary devices are symmetrically distributed around the concrete specimen, namely on the four corners of the lower plate 7 of the press; The device includes a force-transmitting steel pipe 1, a disc spring 2, a connecting plate 3, a guiding steel column 4, a test bench 5, a press upper plate 6, a press lower plate 7 and bolts 8. The connecting plate 3 and the guide steel column 4 are connected by welding, and the disc spring 2 and the force transmission steel pipe 1 pass through the guide steel column 4 in order to be stacked. Such asimage 3 As shown, the connecting plate 3 and the lower plate 7 of the press are connected by bolts 8.

[0018]Such asimage 3 The rigid auxiliary system can be adjusted to meet the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com