No-frosting air source heat pump system

An air source heat pump and frosting technology, which is applied in air conditioning systems, heat pumps, space heating and ventilation, etc., can solve the problems of low heating efficiency, discontinuous heating, and repeated defrosting, so as to prolong the service life and avoid repeated defrosting. The process of defrosting and the effect of reducing the pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

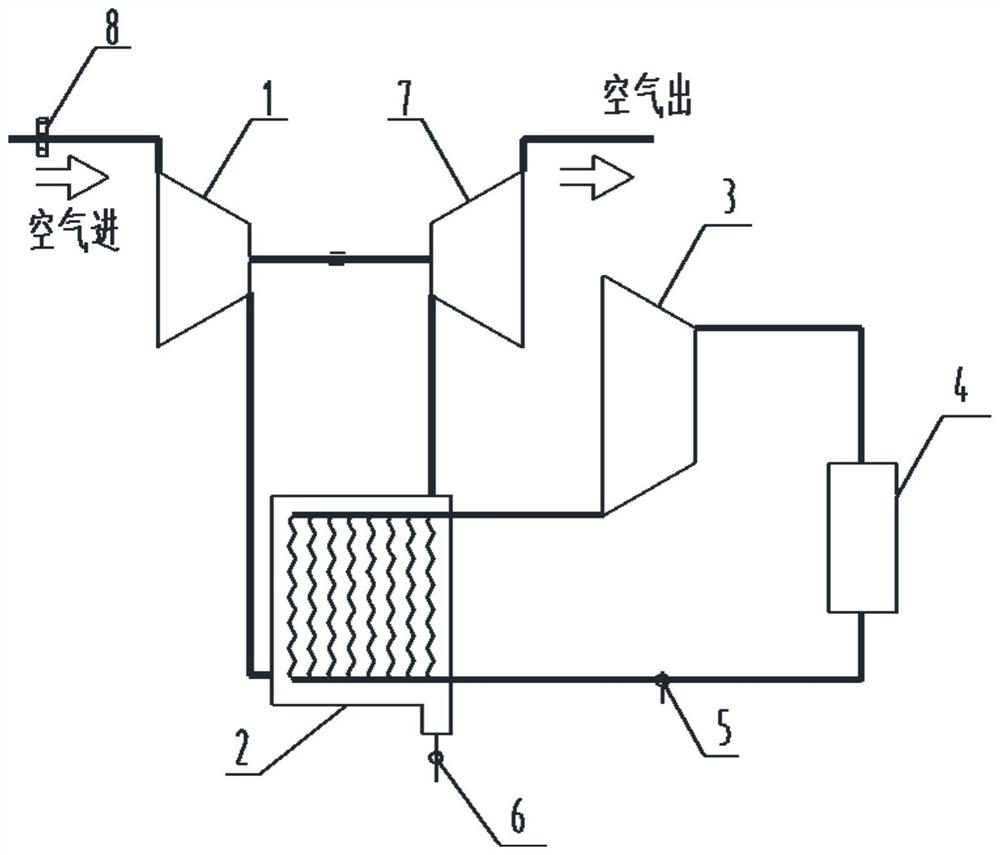

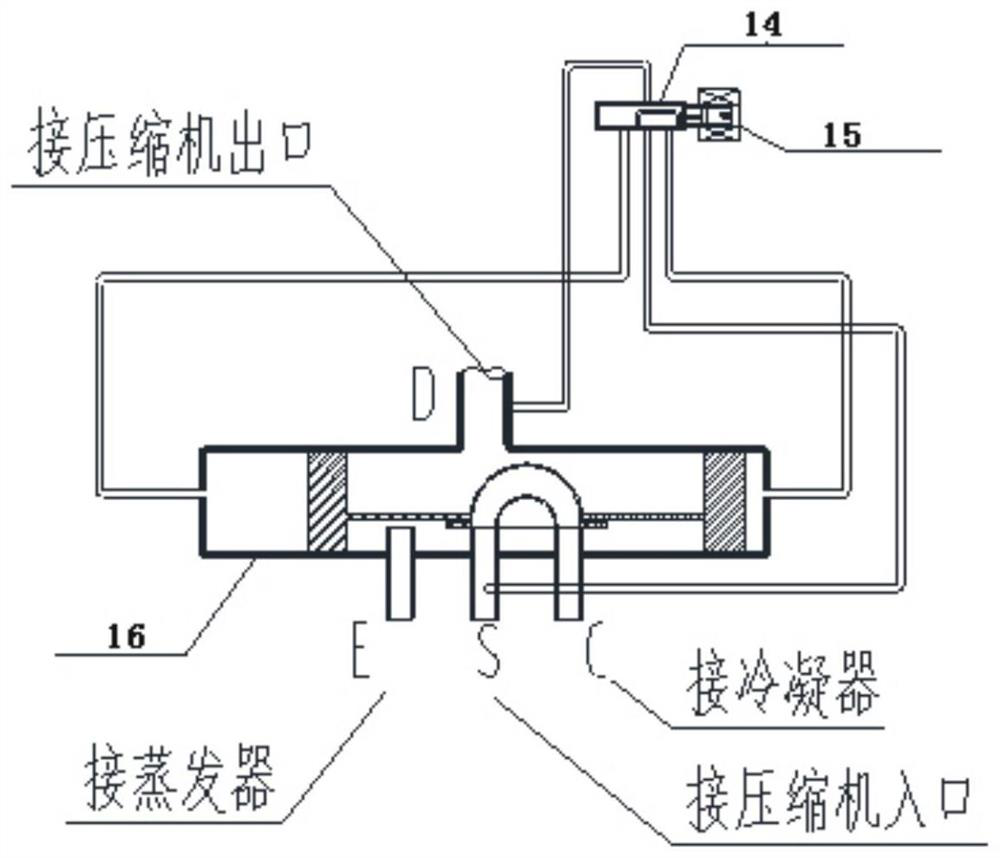

Embodiment 1

[0033] A non-frosting air source heat pump system includes a heating cycle at a low-temperature end and a heating cycle at a high-temperature end. The heating cycle at the low temperature end is an open compressed air heating cycle; the heating cycle at the low temperature end is that the filter 8 is connected to the compressor one 1 through the pipeline, and the compressor one 1 is connected to the intermediate heat exchanger 2 through the pipeline, and the intermediate heat exchanger 2 is connected to the expansion device 7 through pipelines, the input shaft of the compressor 1 is directly mechanically connected to the main shaft of the expansion device, and the air side of the intermediate heat exchanger is provided with a condensate discharge device 6; the high-temperature heating cycle is closed-type wet vapor compression heating Cycle; the high-temperature heating cycle is connected in sequence by the intermediate heat exchanger 2, the second compressor 3, the condenser 4...

Embodiment 2

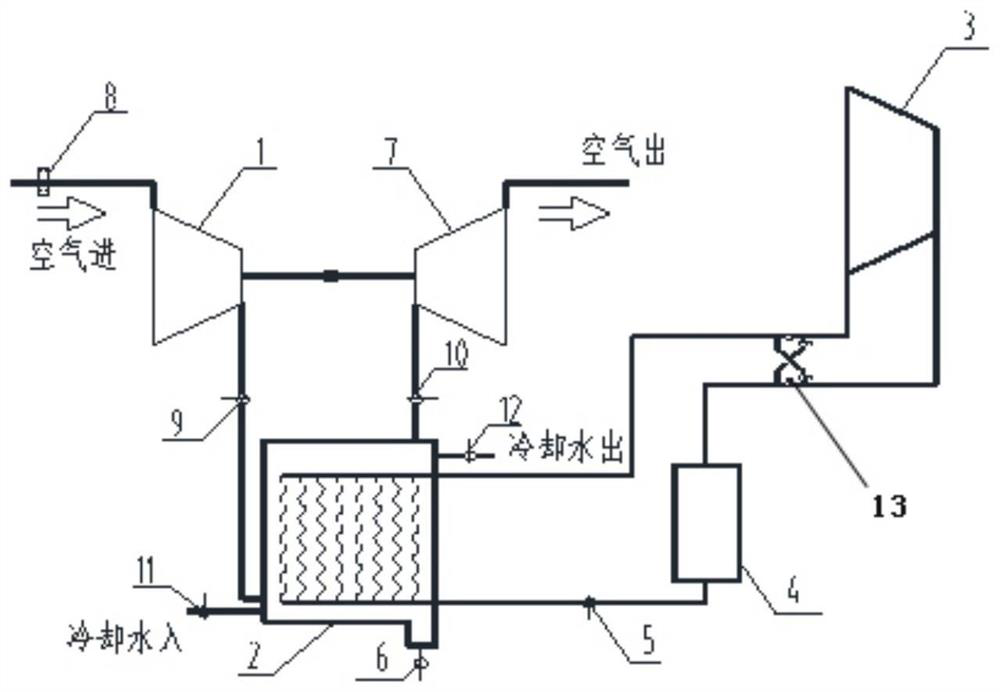

[0039] A heat pump system with air source in winter and water cooling in summer, including a heating cycle at a low-temperature end and a heating cycle at a high-temperature end. The heating cycle at the low temperature end is an open compressed air heating cycle; the heating cycle at the low temperature end is that the filter 8 is connected to the compressor one 1 through the pipeline, and the compressor one 1 is connected to the intermediate heat exchanger 2 through the pipeline, and the intermediate heat exchanger 2 is connected to the expansion device 7 through pipelines, the input shaft of the compressor 1 is directly mechanically connected to the main shaft of the expansion device, and the air side of the intermediate heat exchanger is provided with a condensate discharge device 6; the high-temperature heating cycle is closed-type wet vapor compression heating Cycle; the high-temperature heating cycle is connected in sequence by the intermediate heat exchanger 2, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com