Chemical supply system for manufacturing semiconductor and purification method thereof

A technology for supplying systems and chemicals, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of unreasonable pipeline cleaning methods, time-consuming and labor-intensive, etc., to save time, reduce risks, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

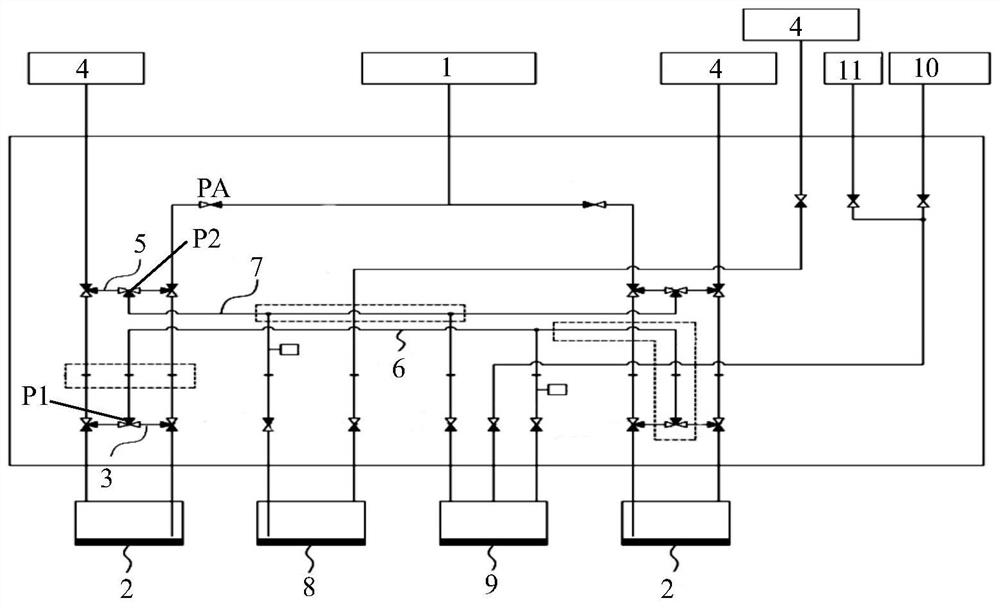

[0039] like figure 1 As shown, a chemical supply system for manufacturing semiconductors includes at least two identical sets of supply equipment and a deposition chamber 1 connected to the liquid outlet of each supply equipment chemical tank, and each set of supply equipment includes a For the chemical tank 2 that stores chemicals that need to be deposited, there is a first bridging pipe 3 between the air inlet and the liquid outlet of the chemical tank 2, and a first three-way valve P1 is set on the first bridging pipe 3, The third port of the first three-way valve P1 is connected to the corresponding port of the first three-way valve P1 at the first bridge pipe 3 of another chemical tank 2, and the air inlet of the chemical tank 2 is connected to the supercharger 4 through a pipeline , the pipeline from the chemical tank 2 to the supercharger 4 and the pipeline from the chemical tank 2 to the deposition chamber 1 are provided with a second bridging pipe 5, and the third of ...

Embodiment 2

[0048] A method of purifying a chemical supply system for the manufacture of semiconductors comprising the steps of:

[0049] 1) When the remaining amount of medicine in one chemical tank 2 is insufficient, open the path that another set of chemical tank 2 is transported to the deposition chamber 1, and at the same time, the current set of supply equipment passes through the first branch 6 or the second branch 7 Transport the medicine to the bridging pipe of another set of supply equipment, and open the bridge pipe to transport the tee in the direction of the deposition chamber 1, so that the medicine in the chemical tank 2 of the current supply equipment can be completely used up;

[0050] 2) When the medicine in the chemical tank 2 of the current set of supply equipment is completely used up, close all directions of the first three-way valve P1 and the second three-way valve P2 of the other set of supply equipment, and open the booster connected to the solvent tank 8 device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com