Automatic cleaning device for annular conveying belt

An automatic cleaning and conveyor belt technology, applied in the field of machinery and equipment, can solve problems such as easy occurrence of safety accidents, affecting production efficiency, and hidden safety hazards, and achieve the effect of solving hidden safety hazards and cleaning dust completely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

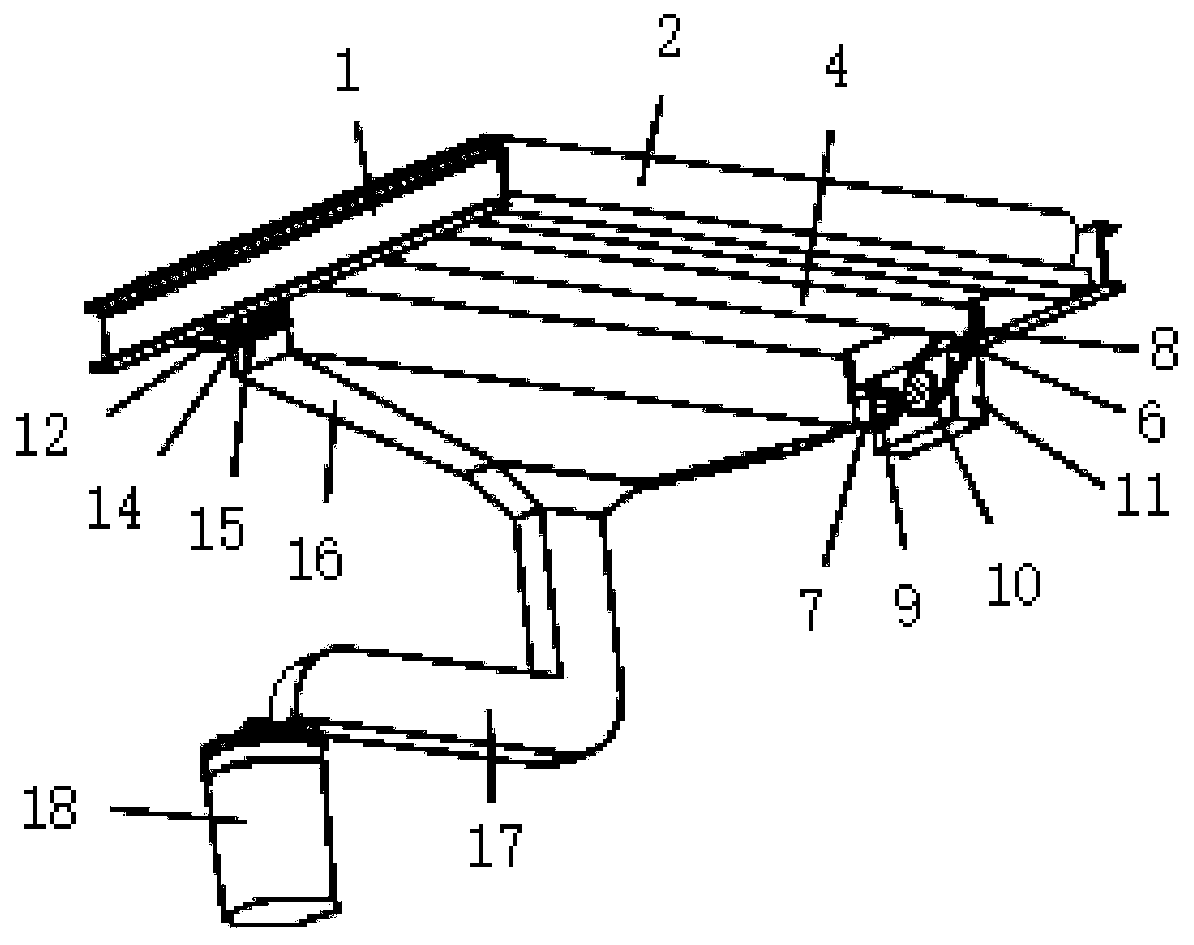

[0020] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: an automatic cleaning device for an endless conveyor belt, including a main body support 1, two main body supports 1 are provided, and the top between the two main body supports 1 is rotatably connected with a conveyor belt 2, two Between the main body brackets 1 and below the conveyor belt 2, a driven roller 4 is rotatably connected, and the driven roller 4 is in contact with the conveyor belt 2. One end of the driven roller 4 is fixedly connected to a No. 2 sprocket 6, and the bottom of one of the main body brackets 1 is fixedly connected to There is a gearbox 11, the input end of the gearbox 11 is fixedly connected with the No. 4 sprocket 10, and the No. 2 chain 8 is connected between the No. 4 sprocket 10 and the No. 2 sprocket 6. The two main body brackets 1 are located between the conveyor belt 2 is provided with a cleaning roller brush 3 below the cleaning roller brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com