A kind of superhydrophobic electric rubber and preparation method thereof

A technology of hydrophobicity and electric power, which is applied in the field of rubber, can solve the problem of insufficient hydrophobicity of rubber, and achieve the improvement of hydrophobicity, the decrease of tensile strength and elongation at break, and the improvement of tensile strength and elongation at break. The effect of length

Active Publication Date: 2022-05-31

HEBEI SILICON VALLEY CHEM CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The present invention proposes a super-hydrophobic electric rubber and its preparation method, which solves the problem that the hydrophobic mobility of rubber is not good enough in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

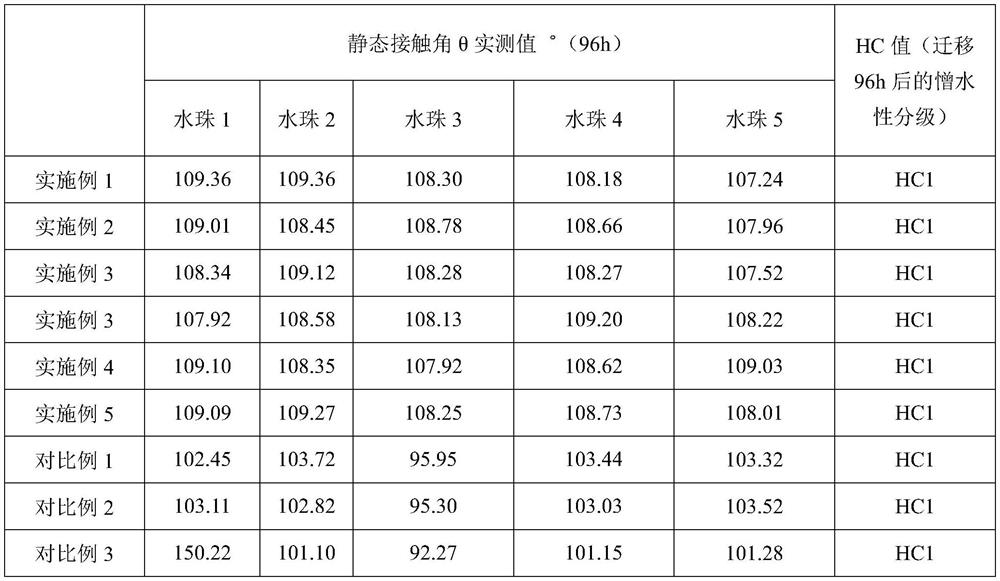

Comparison scheme

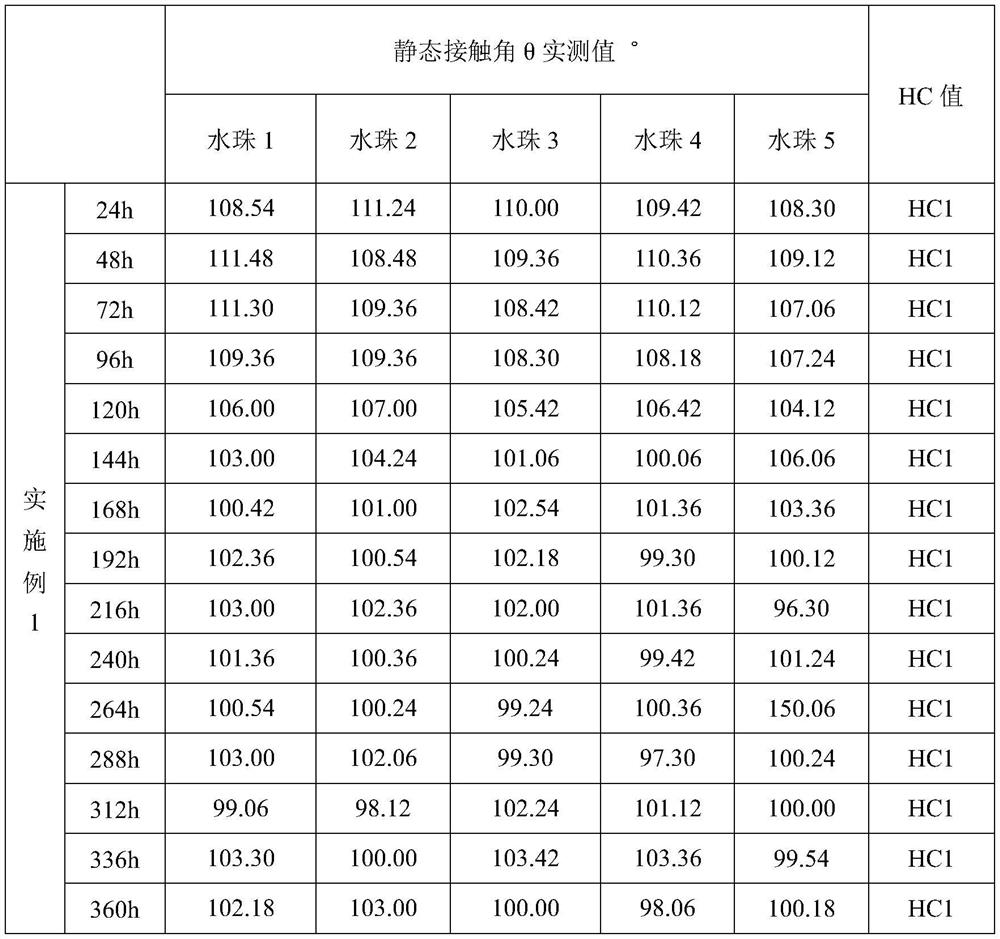

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of rubber, and proposes a super-hydrophobic electric rubber, comprising: 30-50 parts of filler, 0-10 parts of sodium polyacrylate, 60-150 parts of sodium silicate, 10-12 parts by mass. Parts of dimethyldiethoxysilane, 3-4 parts of vinyl silane coupling agent, 1-2 parts of ethyl orthosilicate, 0-3 parts of pigment, 10-15 parts of white carbon black, 35-55 parts of γ ‑Trifluoropropylmethicone, 10‑15 parts hydroterminated polysiloxane, 8‑15 parts α‑vinyl‑α, ω‑dialkoxypolydimethylsiloxane, 3 parts ‑15 parts structuring control agent, 5‑12 parts vulcanizing agent, 150‑180 parts water, 5‑8 parts silica, 3‑6 parts aluminum hydroxide, 4‑6 parts polypropylene fiber, 1‑2 parts 2 , 5‑Dimethyl‑2, 5‑di-tert-butylperoxyhexane. Through the above technical solution, the problem of insufficient hydrophobic migration of rubber in the prior art is solved.

Description

A kind of super-hydrophobic power rubber and preparation method thereof technical field The invention belongs to technical field of rubber, relate to a kind of super-hydrophobic power rubber and preparation method thereof. Background technique During the long-term operation of power grid system equipment, it is often exposed to different pollution conditions, and the operating environment is very harsh. The hydrophobicity of composite insulators will be lost over time during the operation of high-voltage lines. The durability of the hydrophobicity of composite insulators in special environments such as dust and high salt spray cannot meet the requirements of anti-pollution flashover in the power grid. At present, the insulator shed is hardened, embrittled, pulverized, the mandrel is loose, pulverized and other problems eventually lead to insulator discharge, arcing, electric corrosion, and even To flashover, short-circuit rupture and other accidents. The composite ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L83/08C08L83/05C08L83/07C08L33/02C08L23/12C08K13/04C08K7/26C08K3/34C08K5/14C08K3/22C08K3/36C08K5/5419C08K5/06

CPCC08L83/08C08L2205/025C08L2205/035C08L2205/16C08K2003/2275C08K2003/222C08K2003/2206C08K2003/2227C08K2003/2241C08L83/04C08L33/02C08L23/12C08L5/04C08K13/04C08K7/26C08K3/34C08K5/14C08K3/22C08K3/36C08K5/5419C08K5/06C08K3/2279

Inventor 宋志强宋利强宋聚强宋福如

Owner HEBEI SILICON VALLEY CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com