A kind of epoxy resin insulation material and its preparation method and application

A technology for epoxy resin and insulating material, applied in the field of epoxy resin insulating material and its preparation, can solve the problems of insufficient hydrophobicity and poor low temperature toughness, solve the problem of filler settlement, improve mechanical strength and impact strength, Evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

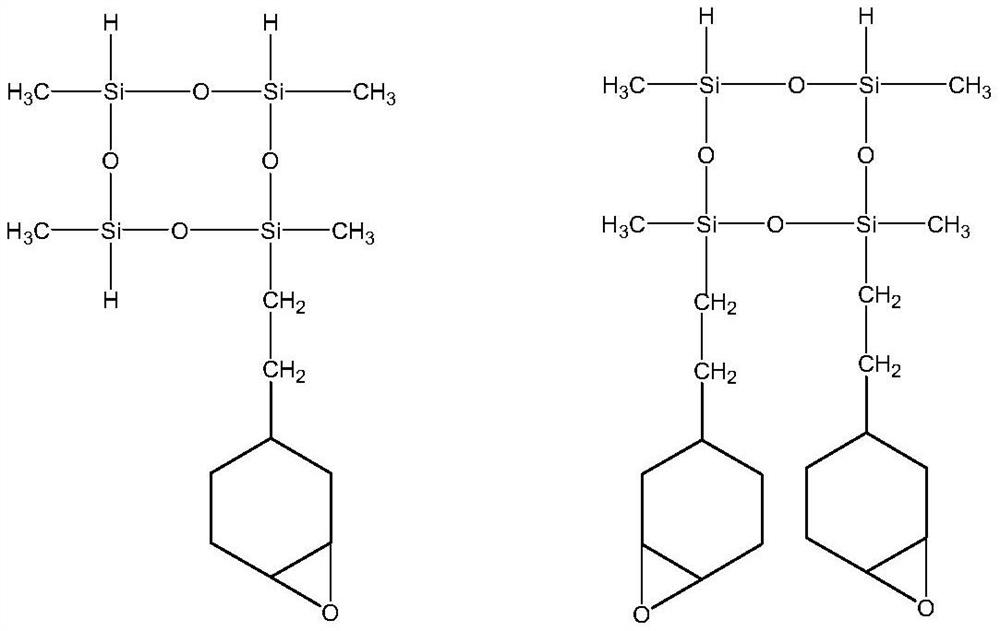

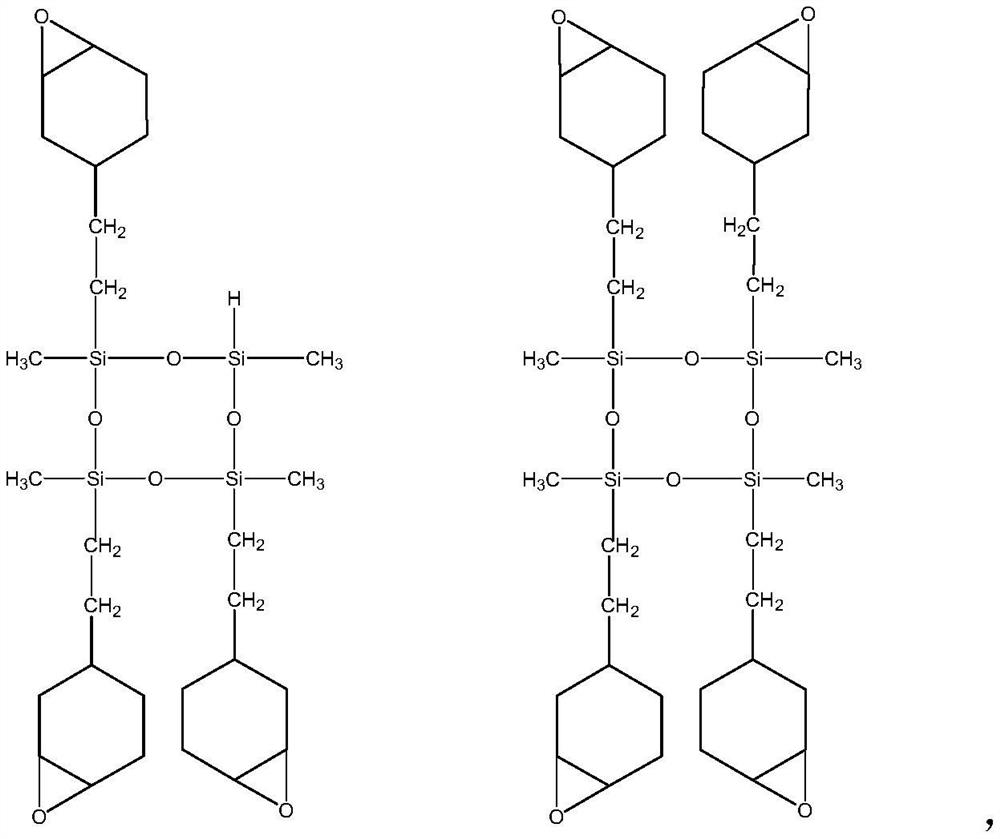

Method used

Image

Examples

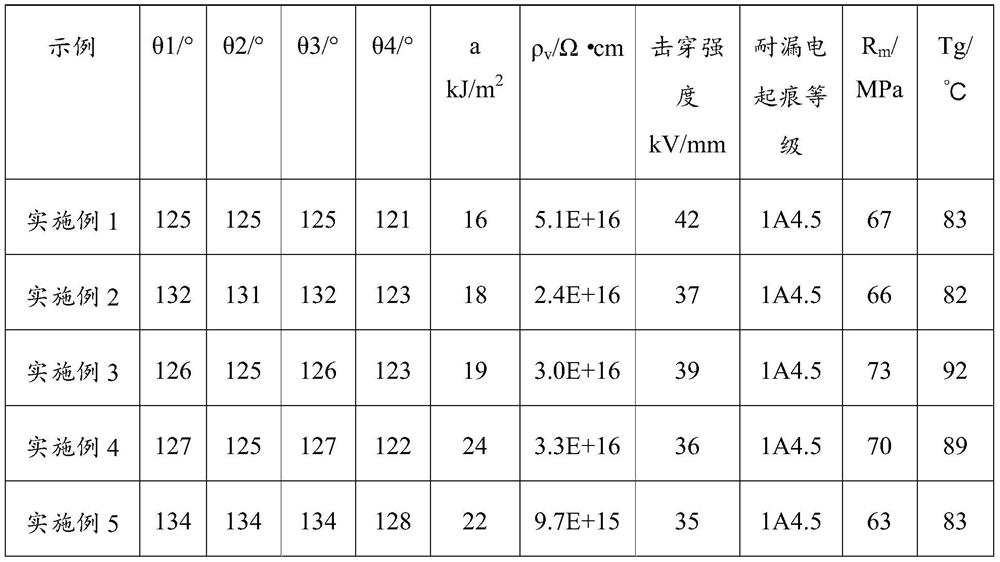

Embodiment 1

[0047] This embodiment provides an epoxy resin insulating material, including, 100g 3,4-epoxycyclohexanecarboxylate-3′,4′-epoxycyclohexane methyl ester, 108g methyltetrahydrophthalophthalate Acid anhydride, 0.6g dimethylbenzylamine, 20g silicone modified resin, 20g particle toughening agent (rubber elastomer particles, the average particle diameter is 40μm), 130g active silica powder, 2g KH560; wherein, active silica powder includes The mass ratio of the first particle fraction and the second particle fraction is 7:3, the median diameter of the first particle fraction is 32 μm; the median diameter of the second particle fraction is 12 μm;

[0048] The preparation method of above-mentioned epoxy resin insulating material comprises,

[0049] Mix 3,4-epoxycyclohexanecarboxylic acid-3′,4′-epoxycyclohexanemethyl ester, silicone modified resin, KH560, and granular toughening agent in a stirring tank, raise the temperature to 80°C, and Vacuum stirring under the condition of 200Pa fo...

Embodiment 2

[0056] This embodiment provides an epoxy resin insulating material, including, 100g 3,4-epoxycyclohexanecarboxylate-3',4'-epoxycyclohexane methyl ester, 125g methyltetrahydrophthalophthalate Acid anhydride, 0.7g dimethylbenzylamine, 40g silicone modified resin, 20g particle toughening agent (rubber elastomer particles, average particle diameter is 40μm), 150g active silica powder, 2g KH560; wherein, active silica powder includes The mass ratio of the first particle fraction and the second particle fraction is 7:3, the median diameter of the first particle fraction is 32 μm; the median diameter of the second particle fraction is 12 μm;

[0057] The preparation method of above-mentioned epoxy resin insulating material comprises,

[0058] Mix 3,4-epoxycyclohexanecarboxylic acid-3′,4′-epoxycyclohexanemethyl ester, silicone modified resin, KH560, and granular toughening agent in a stirring tank, raise the temperature to 80°C, and Vacuum stirring under the condition of 200Pa for 2h...

Embodiment 3

[0065] This embodiment provides an epoxy resin insulating material, comprising, 100g bis((3,4-epoxycyclohexyl)methyl)adipate, 101g methyltetrahydrophthalic anhydride, 0.7g di Methylbenzylamine, 40g organosilicon modified resin, 20g particle toughening agent (rubber elastomer particle, average particle diameter is 40 μ m), 137g active microsilica powder, 2g KH560; Wherein, active microsilica powder comprises mass ratio and is 7: 3. The first particle fraction and the second particle fraction, the median diameter of the first particle fraction is 32 μm; the median diameter of the second particle fraction is 12 μm;

[0066] The preparation method of above-mentioned epoxy resin insulating material comprises,

[0067] Mix bis((3,4-epoxycyclohexyl)methyl)adipate, silicone modified resin, KH560, and particle toughening agent in a stirring tank, raise the temperature to 80°C, and Stir in vacuum for 2 hours under the condition to prepare the premixed modified cycloaliphatic epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com