Thread jumping prevention device for textile processing

A textile and anti-jumping technology, which is applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as easy thread breakage, inconvenient adjustment of angle, inconvenient spinning thread tension, etc., to achieve The effect of preventing disconnection and facilitating buffering work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

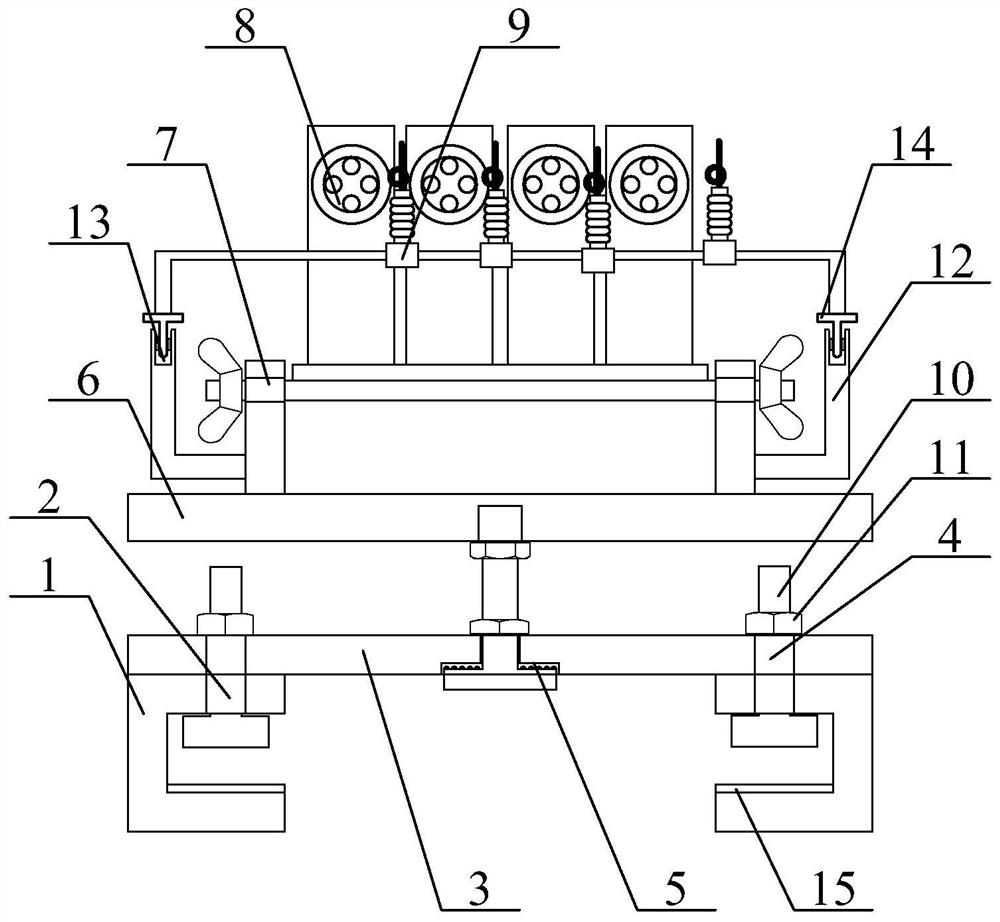

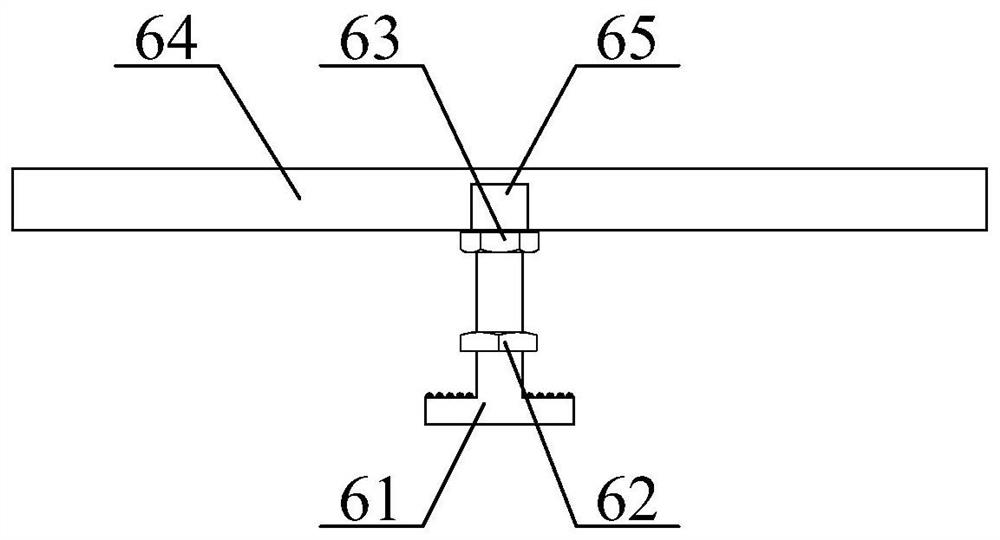

[0041] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an anti-jumping device for textile processing includes a fixing seat 1, a connecting hole 2, a first connecting plate 3, a fixing hole 4, an insertion slot 5, a rotatable locking support plate structure 6, and an adjustable support and fixing Plate structure 7, protective tension guide tube structure 8, pullable buffer guide hook structure 9, inverted T-shaped threaded rod 10, square head nut 11, L-shaped support plate 12, fixing groove 13, T-shaped rotating seat 14 and anti-slip mat 15;

[0042] The connecting holes 2 are set in the middle position of the upper end of the fixing base 1 respectively; the fixing bases 1 are respectively set on the left and right sides of the lower end of the first connecting plate 3; The middle position of the left and right sides of the plate 3 is set correspondingly to the connection hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com