Photovoltaic power station intelligent inspection equipment

A photovoltaic power station, intelligent inspection technology, applied in the direction of mechanical equipment, supporting machines, springs/shock absorbers, etc., can solve the problems of inconvenient shielding work, inconvenient braking work, inconvenient detection of photovoltaic power generation panels, etc. To achieve the effect of convenient positioning and detection work, and convenient buffering work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

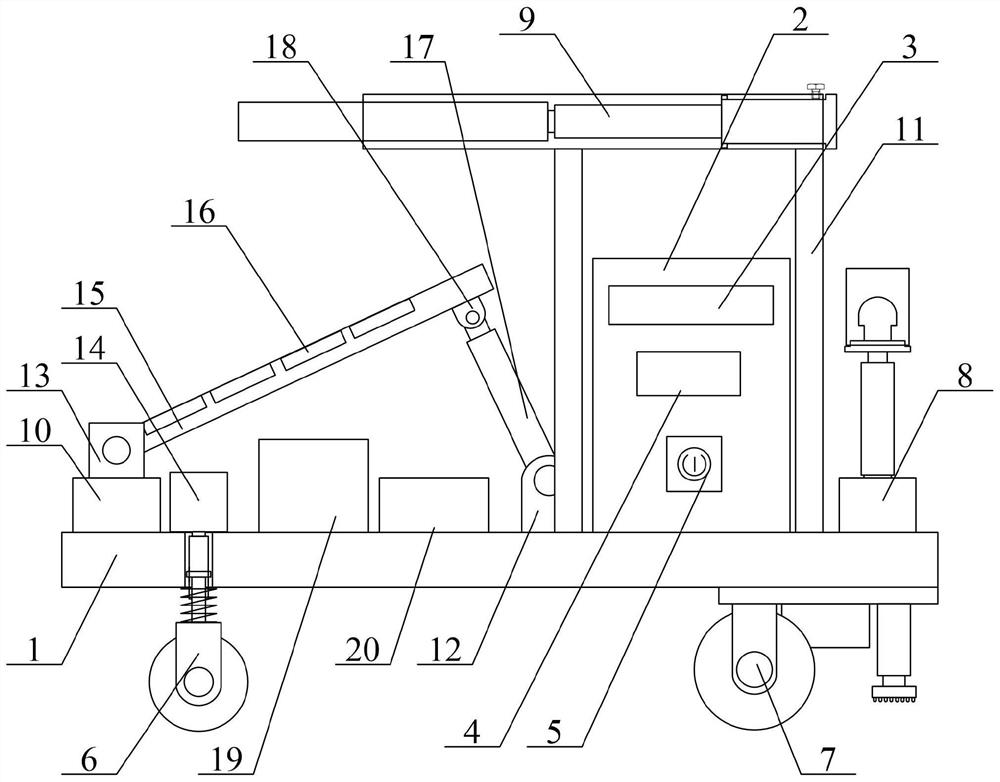

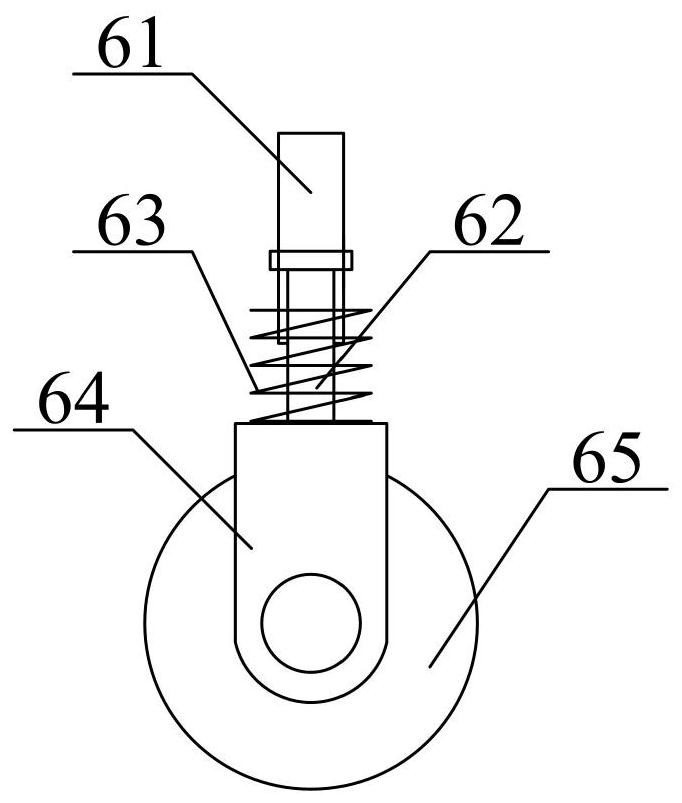

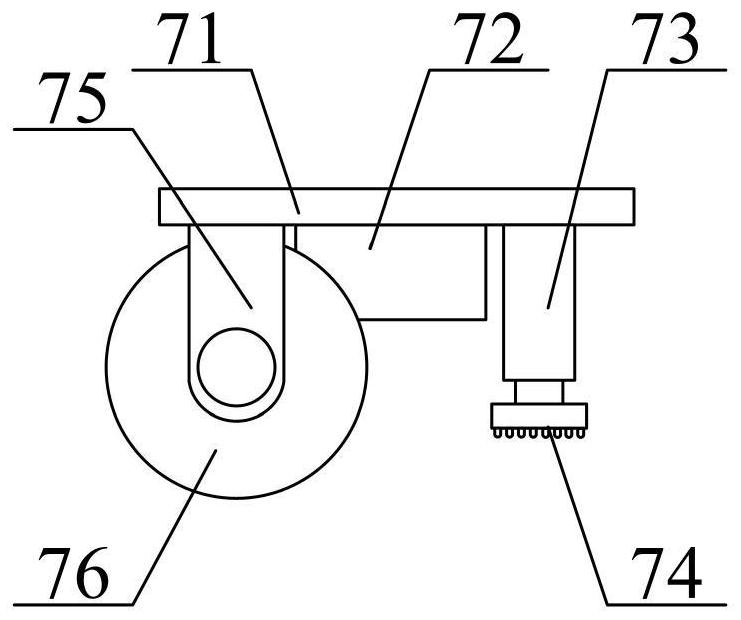

[0037] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an intelligent inspection equipment for a photovoltaic power station includes an inspection base 1, a control box 2, a PLC 3, a wireless transmission module 4, a power switch 5, a moving wheel structure 6 that can be buffered and moved, and a brake power push seat structure 7. Liftable and rotating inspection seat structure 8, retractable shield box structure 9, connecting block 10, support rod 11, U-shaped support seat 12, U-shaped frame 13, steering motor assembly 14, rotating plate 15, photovoltaic panel 16. Push the electric rod assembly 17, the first connection seat 18, the battery 19 and the converter 20, the control box 2 is bolted to the middle position on the upper right side of the inspection base 1; the PLC3 is bolted to the control The upper middle of the front surface of the box 2; the wireless transmission modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com