Semi-T-shaped three-step metallized safety film capacitor

A technology of metallization and safety film, which is applied in the direction of thin film/thick film capacitors, laminated capacitors, fixed capacitor shells/packages, etc., can solve problems such as poor ability to withstand overcurrent, capacitor heating, and insufficient flow capacity, etc., to achieve improvement The ability to withstand current and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

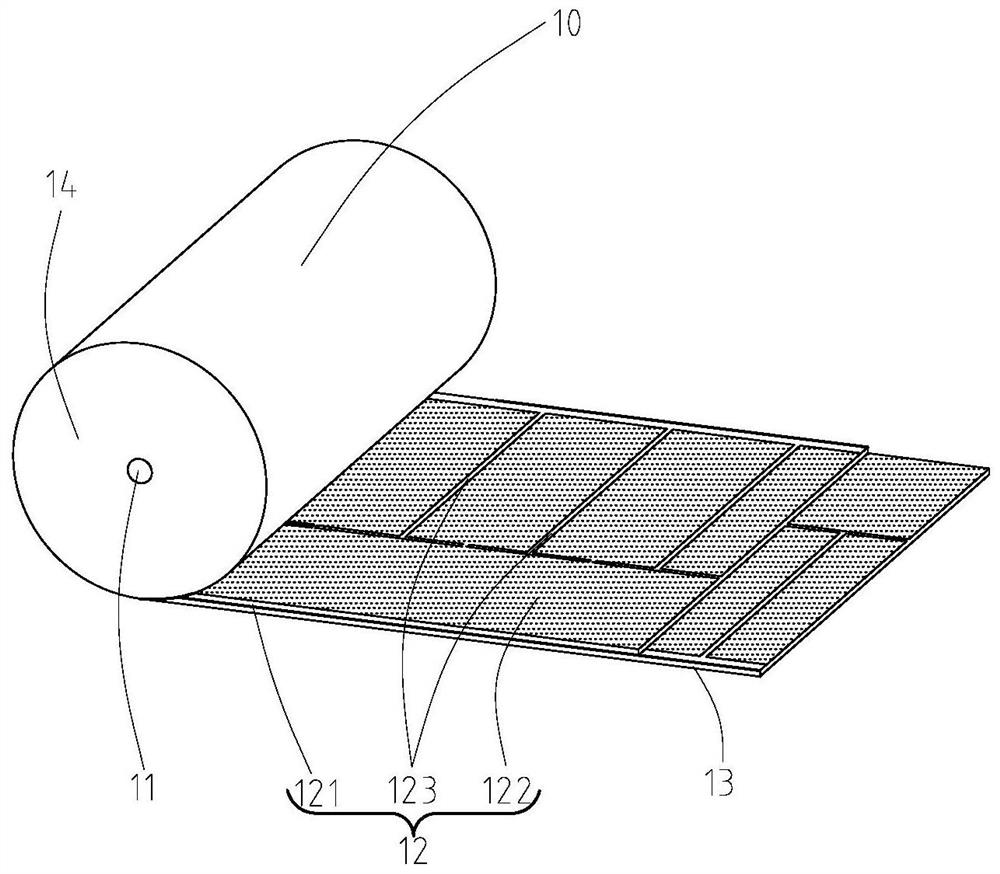

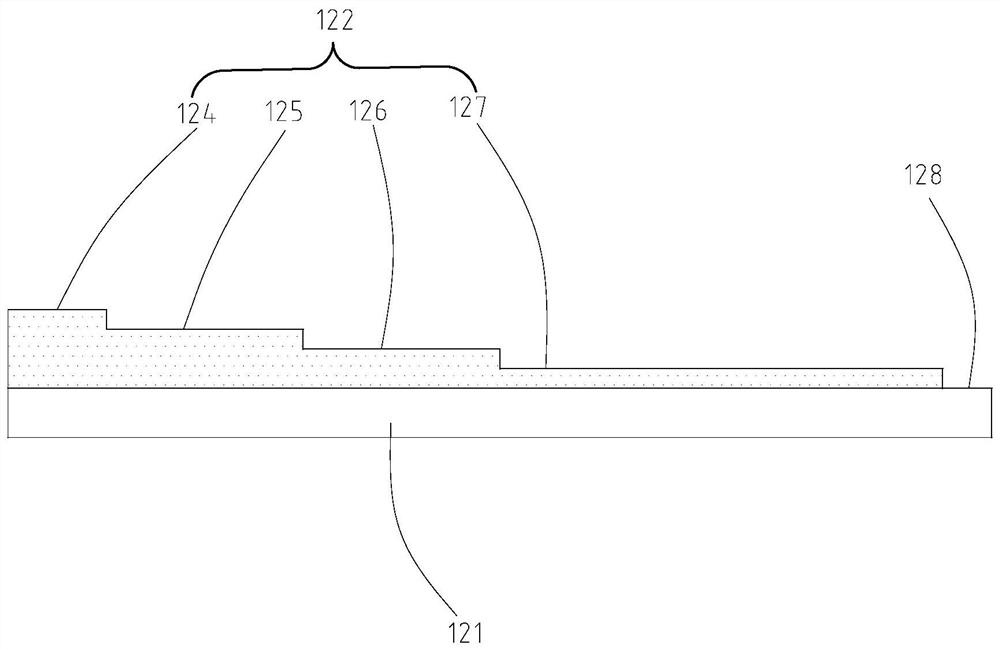

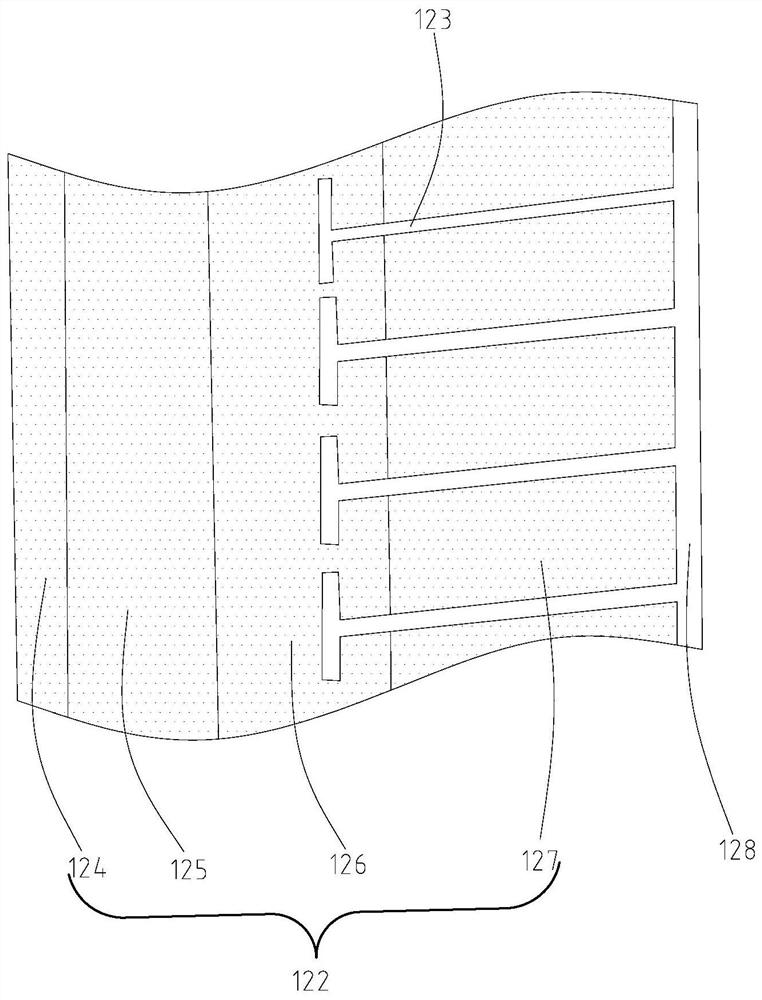

[0020] Such as Figure 1 to Figure 3 As shown, it is a schematic structural diagram of a half-T type three-step metallized safety film capacitor provided by the present invention. It should be noted that the capacitor 10 itself should be a prior art, only some elements are shown in this embodiment, and the rest are not shown. The half-T-shaped three-step metallized safety film capacitor 10 includes an insulating mandrel 11 , and first and second metallized safety films 12 , 13 stacked and wound around the insulating mandrel 11 . The first and second metallized safety films 12, 13 have the same structure. It is conceivable that the half-T-shaped three-step metallized safety film capacitor 10 also includes some other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com