Circuit moudel

A technology for circuit modules and circuit devices, applied in circuits, electrical components, electric solid devices, etc., can solve the problem of thick lead 101 and other problems, and achieve the effects of large current capacity and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

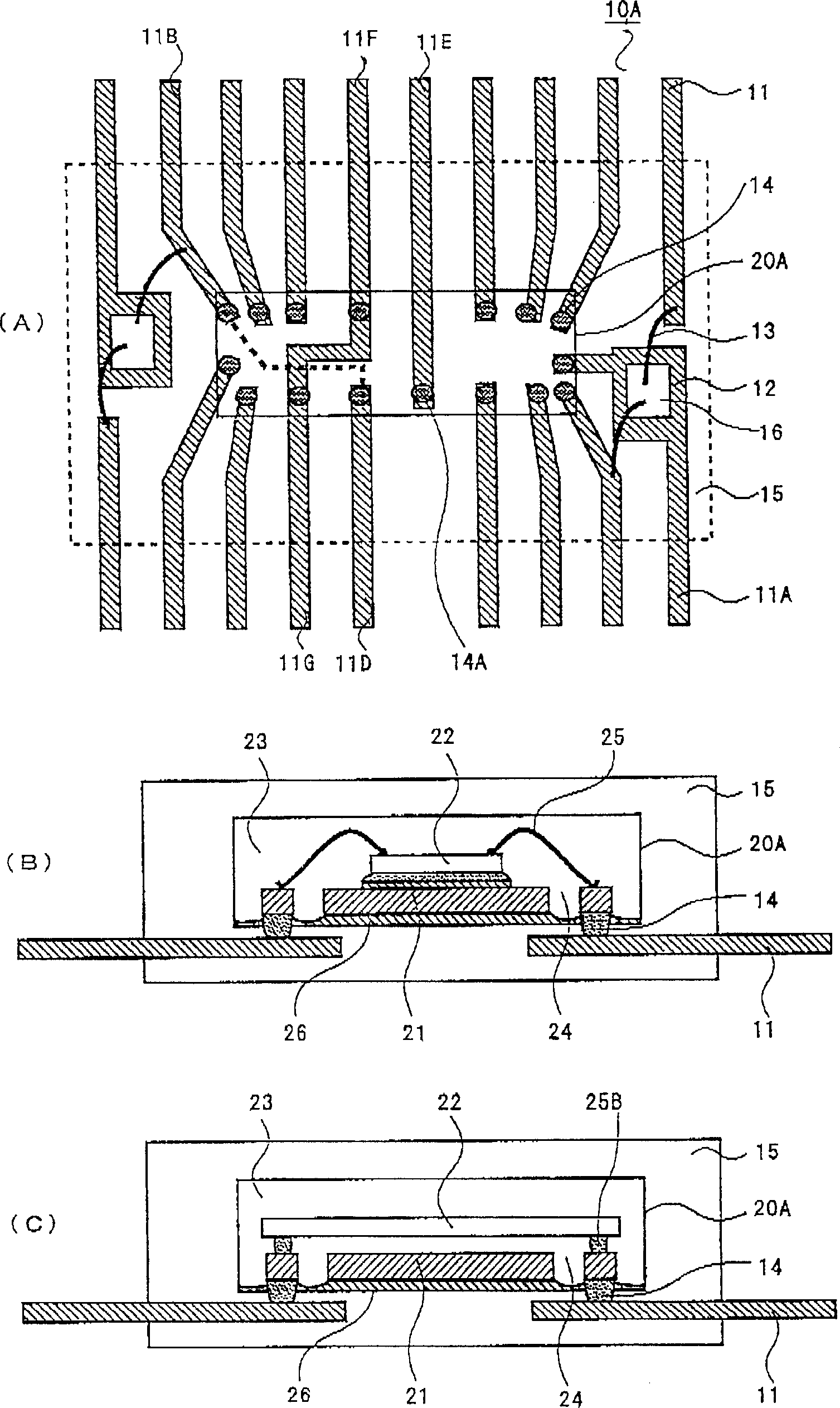

[0025] refer to figure 1 The configuration of the circuit module 10A of the present invention will be described. figure 1 (A) is a plan view of the circuit module 10A, figure 1 (B) is its cross-sectional view.

[0026] As can be seen from the figure, in the circuit module 10A of the present invention, a thin circuit device such as a SIP provided with external connection electrodes is mounted on a lead frame and resin-sealed. With this structure, many components can be mounted at one time, and a circuit device in which external electrodes are provided only on the back surface can be realized as a module using lead wires. Even if the circuit module 10A is mounted on a printed circuit board, a ceramic substrate, or a metal substrate (hereinafter referred to as a mounting substrate), thermal stress can be reduced by the leads 11 and heat dissipation can be improved.

[0027] In the circuit module 10A, the circuit device 20A is mounted on the leads 11 . Furthermore, semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com