Freeze-drying film cloth production system

A production system and film cloth technology, which is applied in the direction of drying, drying solid materials, and drying solid materials without heating, etc., can solve the problems of affecting the shelf life of mask products, poor liquid uniformity, and sticky liquid materials, etc., to achieve guaranteed Storage period and product stability, avoid deterioration, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

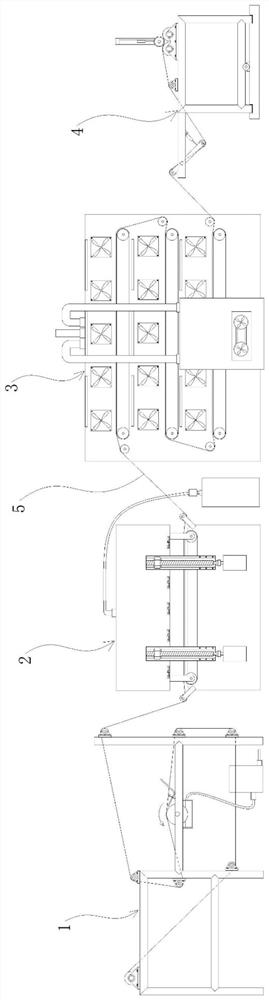

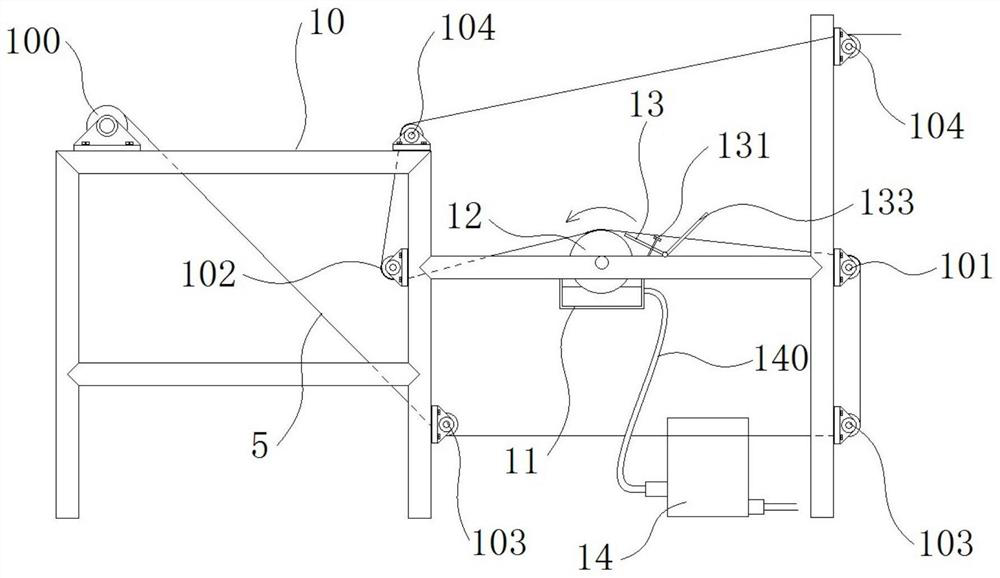

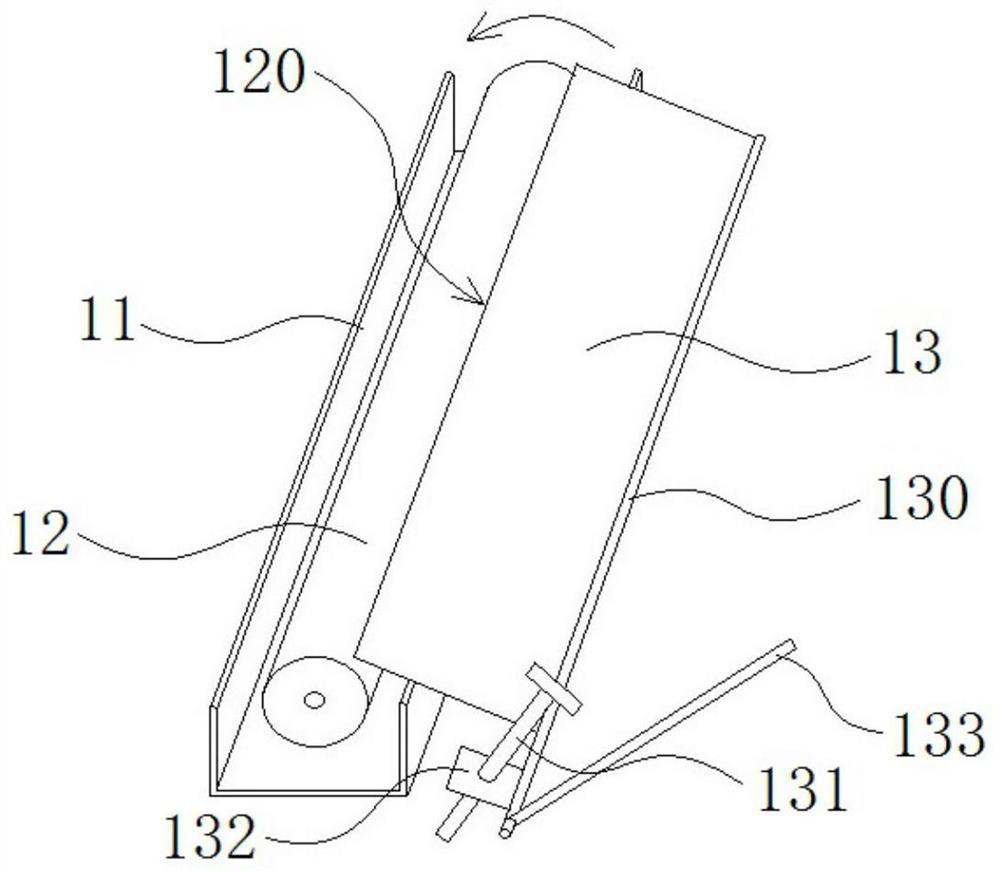

[0037] Specific embodiment 1 of the freeze-dried membrane cloth production system of the present invention, such as Figure 1 to Figure 8 As shown, the freeze-dried film cloth production system includes a film cloth feeder 1, a film cloth freeze dryer 2, a freeze-dried film cloth drying equipment 3 and a film cloth rolling machine 4 arranged sequentially along the film cloth length direction; The feeding machine comprises a first frame 10, a storage tank 11, a guide roller and a feeding roller 12 which are rotatably installed on the first frame 10, and the storage tank 11 is arranged on the lower side of the feeding roller 12 at intervals in parallel. The lower surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com