Continuous drilling, debris discharging and pouring integrated pile driving tool capable of preventing hole collapse

A tool and hole breaking technology, which is applied in percussion drilling, rotary drilling, construction, etc., can solve the problems of adding retaining walls, taking too much time, occupying, etc., and achieve the effects of improved rock breaking efficiency, reliable pouring, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

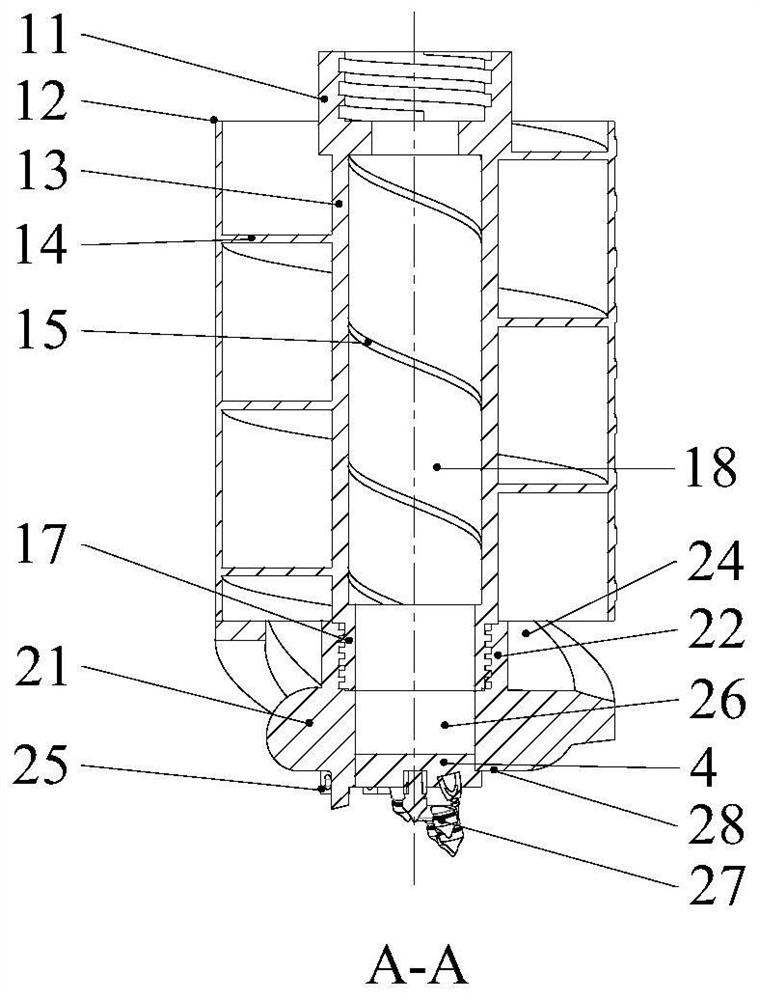

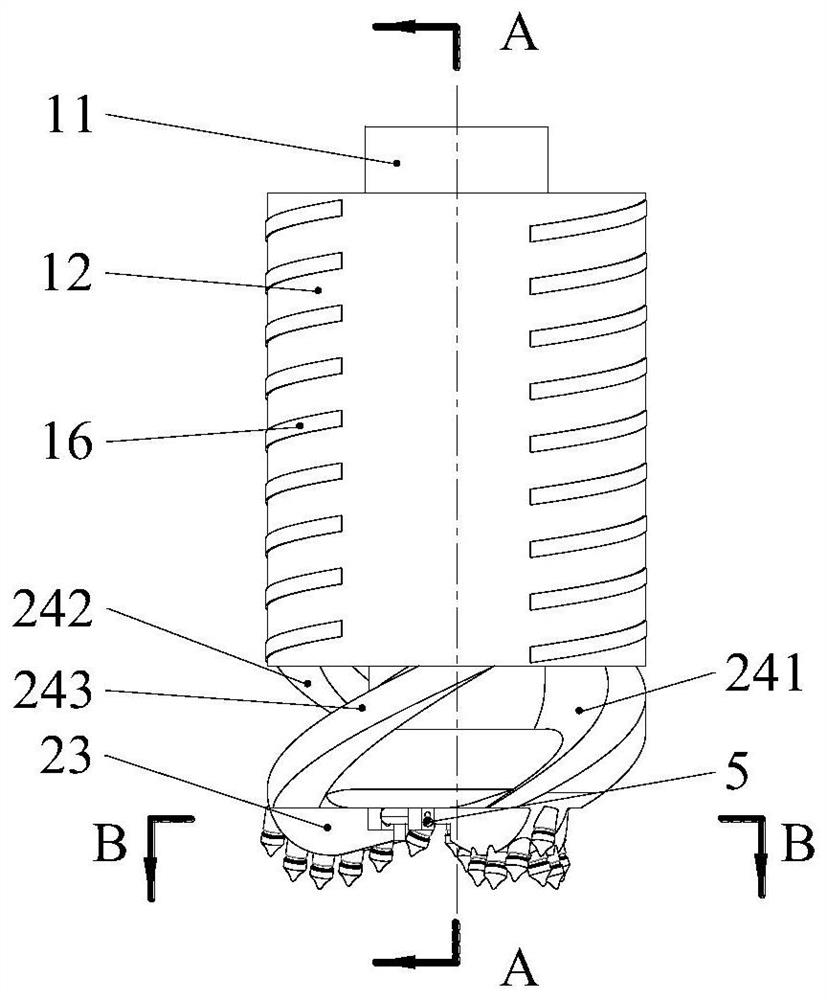

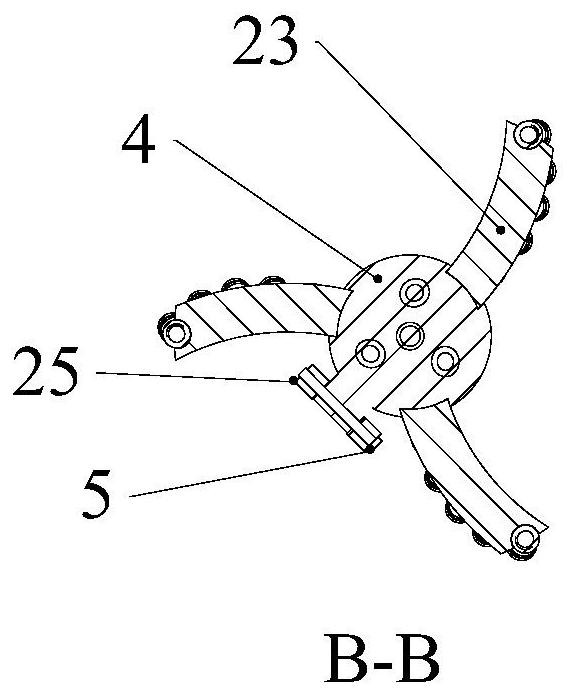

[0028]In the above-mentioned one embodiment, the circulation device, the rotary drilling bit and the pouring mechanism are used to realize efficient drilling, synchronous chip removal, and continuous pouring. In this embodiment, the circulation device transmits the torque and drilling pressure to the rotary drilling bit, and the equipment starts piling operation. At the same time, the circulation device realizes synchronous chip removal; there is no need to replace the pouring equipment, and efficient continuous pouring operation is realized. When drilling normally, under the action of axial pressure and circumferential force, the drill teeth 27 crush the rock or soil by crushing or cutting, and discharge the cuttings from the inside to the outside; the cuttings discharged to the periphery pass through the rock The mutual extrusion between the cuttings will take the cuttings out of the ground from the bottom to the top through the screw conveyor 43 and the screw conveyor 14 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com