Liner tube feeding device and liner tube feeding method for horizontal drill hole under pressure

A technology of horizontal drilling and pressure-holding devices, applied in drilling equipment and methods, drilling equipment, directional drilling, etc. Problems such as yield attenuation can be avoided to achieve the effect of avoiding clogging, stabilizing the connection and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

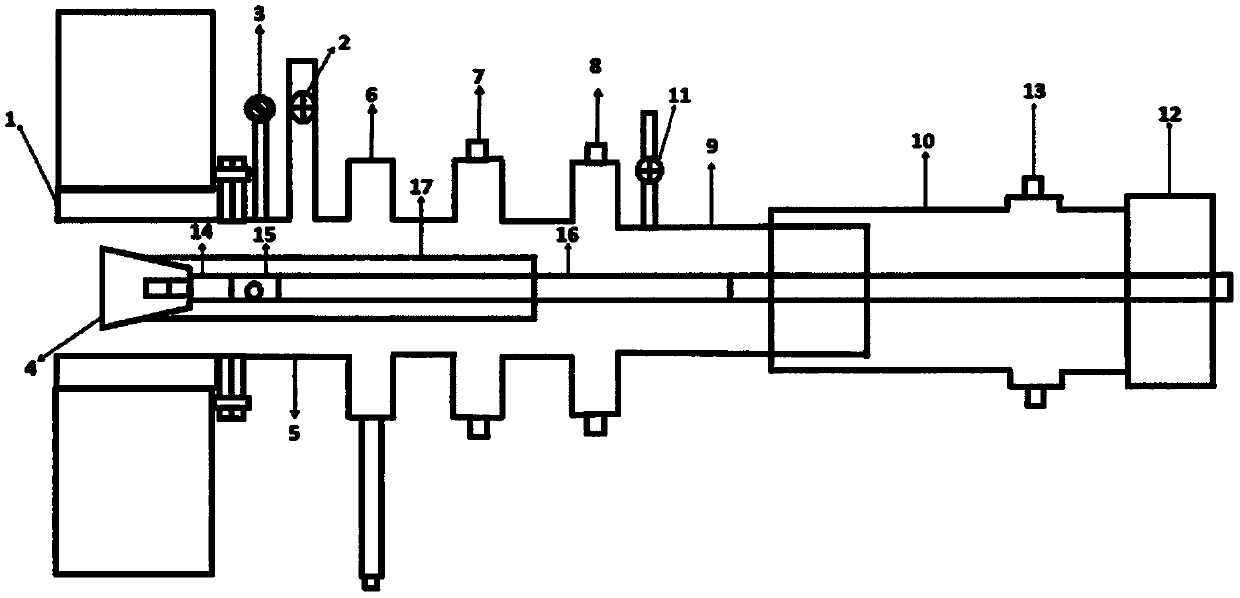

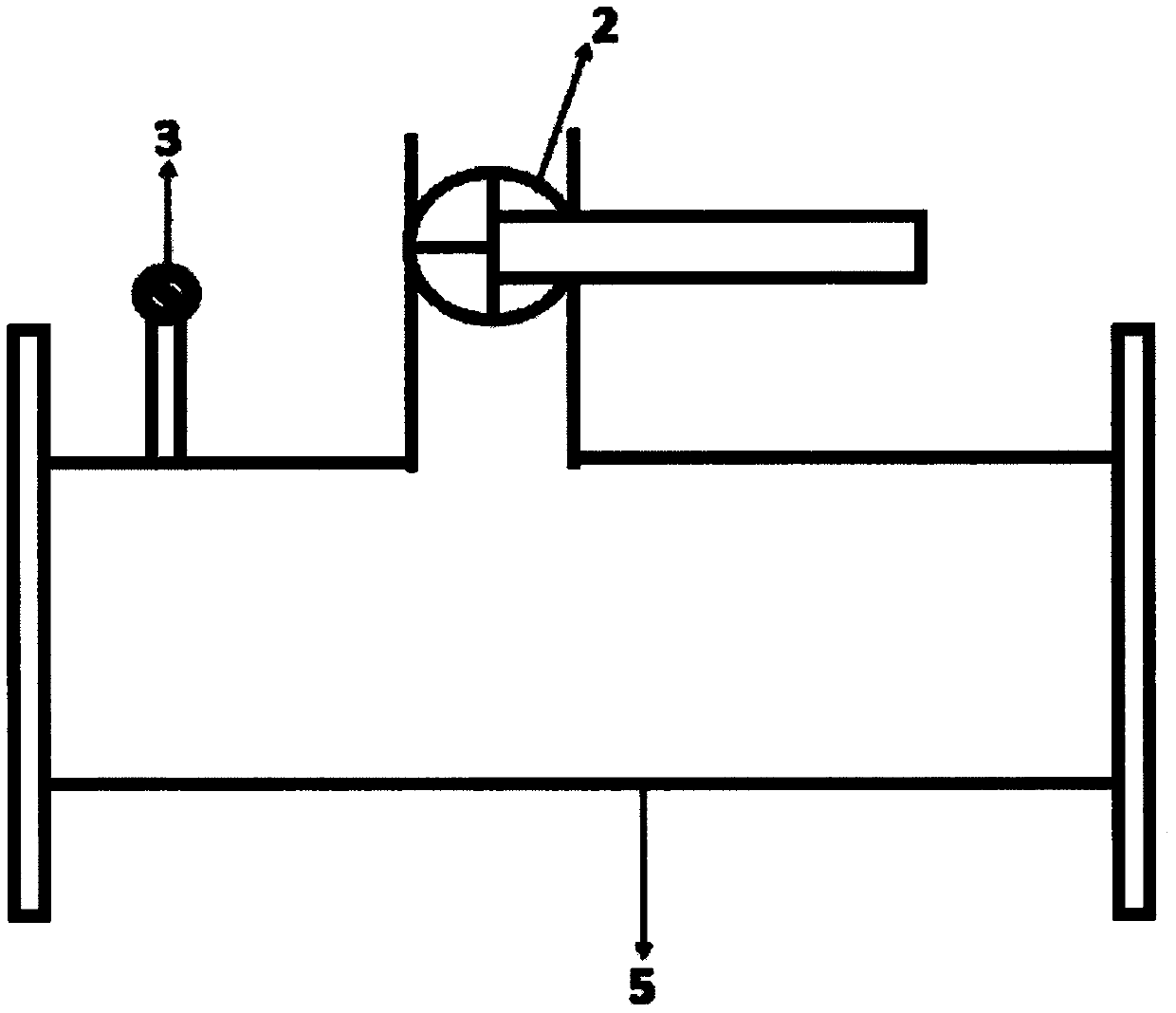

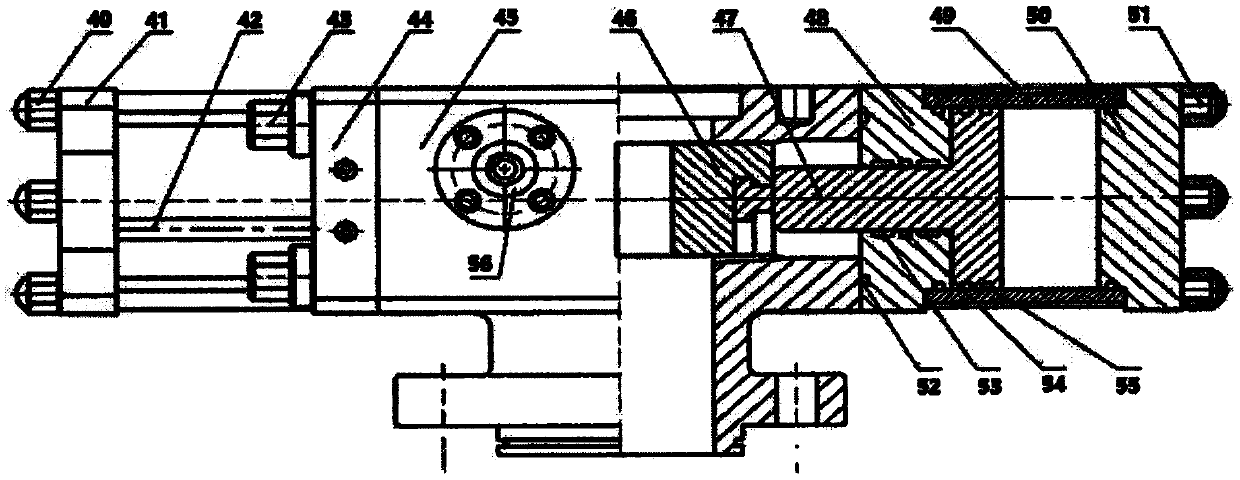

[0039]see figure 1 and figure 2 , the present invention discloses a liner feeding device for a pressurized horizontal borehole, comprising several liner pipes 17, several drill pipes 16 and a hole pressure maintaining device for the horizontal borehole, the liner pipe is provided with an axial A hollow pipe hole, the inner diameter of the liner is larger than the outer diameter of the drill pipe, the pipe hole is suitable for the drill pipe to be inserted and passed through, and the length of the drill pipe is preferably longer than the length of the liner. The orifice pressure maintaining device is provided with a liner channel suitable for the liner to be inserted and passed through, and the orifice pressure maintaining device includes a tee joint 5, a gate Plate valve 6, first liner holder 7, blowout preventer 8, first cylinder 9, second cylinder 10, second liner holder 13 and annular sealer 12, the tee short The joint is a T-shaped three-way short joint, the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com