Device and method for improving roadway base plate anchor rod anchor cable pore-forming efficiency and anchoring performance

A technology of anchoring performance and anchor rods, which is applied in the installation of anchor rods, earthwork drilling, mining equipment, etc., can solve the problems of difficult hole forming, poor anchoring effect, and easy clamping of brazing, etc., and achieves convenient use, improved construction efficiency, and prevents The effect of brazing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

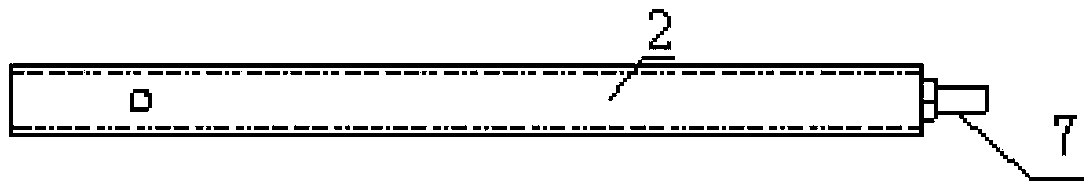

[0036] A device for improving the hole-forming efficiency and anchoring performance of anchor rods and cables on the floor of the roadway, including a special drill pipe 1, a connecting rod 2 and a rod extractor 3; the length of the special drill pipe 1 is set to be L 1 , the length of connecting rod 2 is L 2 , the stroke of the drilling rig is L, and the maximum distance between the head of the drilling rig and the floor of the roadway is H 1 , the minimum distance is H 2 , in order to ensure that the device can normally drill holes, it must satisfy L 1 1 , in order to ensure that the special drill pipe is fully inserted into the hole after two drillings, the L 1 2 >H 2 .

[0037] The special drill rod 1 is a self-drilling hollow steel pipe, the internal diameter of which is 8-12mm larger than the outer diameter of the common drill rod 6, and 2-4mm larger than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com