Lap joint structure and process of polymer self-adhesive film waterproof coiled material and asphalt waterproof coiled material

A technology of bituminous waterproofing membrane and polymer waterproofing, applied in infrastructure engineering, tools for roof engineering, roofing using flexible materials, etc., can solve the problems of poor lap joint effect, damage and loopholes, and no auxiliary tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

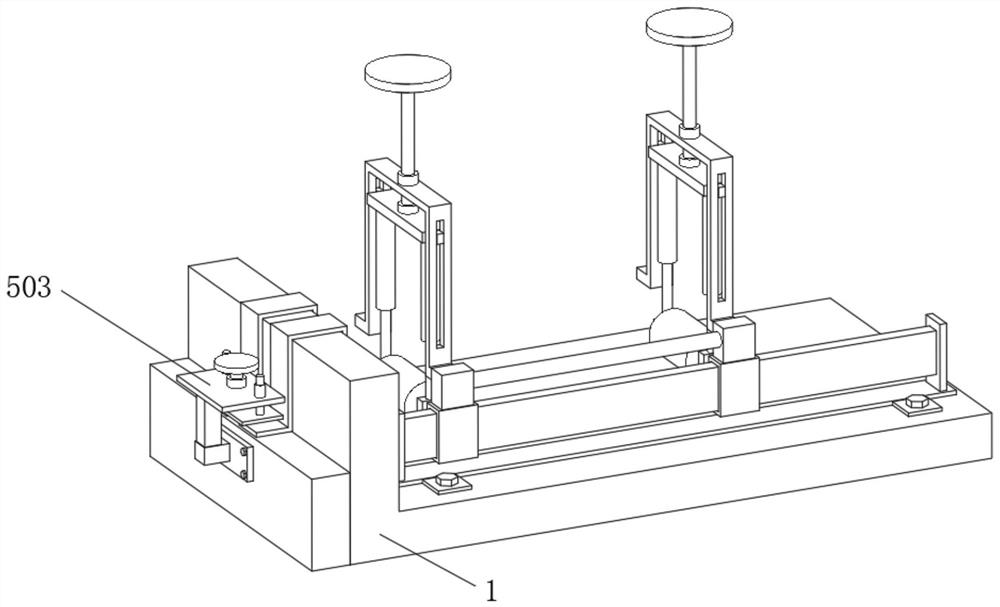

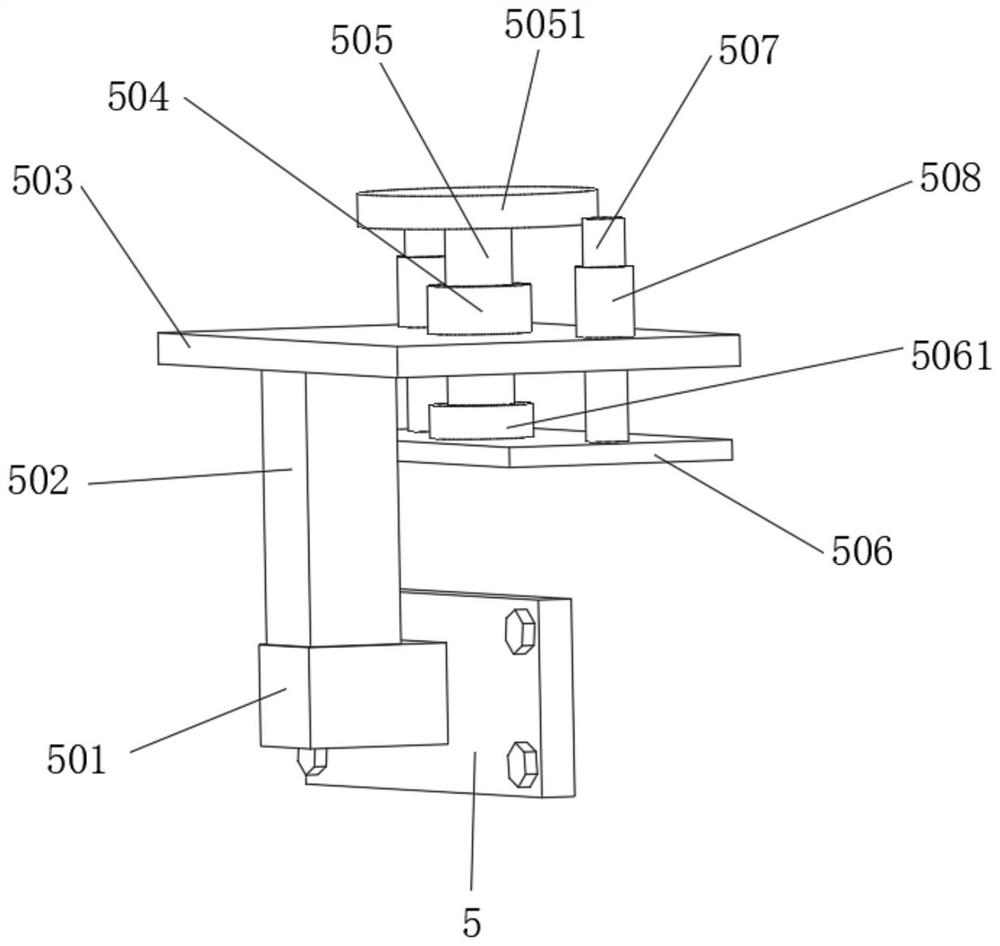

[0034] The embodiment of the present invention provides the overlapping structure and technology of polymer self-adhesive film waterproofing membrane and asphalt waterproofing membrane, such as Figure 1-8 As shown, it includes the wall body 1, the polymer waterproof membrane body 2, the asphalt waterproof membrane body 3 and the overlapping membrane 4, the polymer waterproof membrane body 2 and the bitumen waterproof membrane body 3 are tiled on the wall body 1, the polymer waterproof membrane main body 2 and the asphalt waterproof membrane main body 3 are separated by a gap of ten centimeters to twenty centimeters, and the overlapping membrane 4 is respectively connected to the polymer waterproof membrane main body 2 and the asphalt waterproof membrane main body 3 The edge of the wall is welded, and the wall main body 1 is provided with a temporary fixing mechanism and a welding pressing mechanism corresponding to the polymer waterproof coiled material main body 2 and the asp...

Embodiment 2

[0044] The embodiment of the present invention provides the overlapping structure and technology of polymer self-adhesive film waterproofing membrane and asphalt waterproofing membrane, such as Figure 1-8 As shown, it includes the wall body 1, the polymer waterproof membrane body 2, the asphalt waterproof membrane body 3 and the overlapping membrane 4, the polymer waterproof membrane body 2 and the bitumen waterproof membrane body 3 are tiled on the wall body 1, the polymer waterproof membrane main body 2 and the asphalt waterproof membrane main body 3 are separated by a gap of ten centimeters to twenty centimeters, and the overlapping membrane 4 is respectively connected to the polymer waterproof membrane main body 2 and the asphalt waterproof membrane main body 3 The edge of the wall is welded, and the wall main body 1 is provided with a temporary fixing mechanism and a welding pressing mechanism corresponding to the polymer waterproof coiled material main body 2 and the asp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com