Segmented hoisting construction method for steel grid frame structure

A segmental hoisting and construction method technology, which is applied in the direction of building construction, construction, and building material processing, can solve the problems of difficulty in controlling the angle of rods and bolt tightening, large number of temporary projects, and low economic efficiency. , to achieve the effect of improving assembly quality and assembly efficiency, reducing high-altitude operation time, and ensuring connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

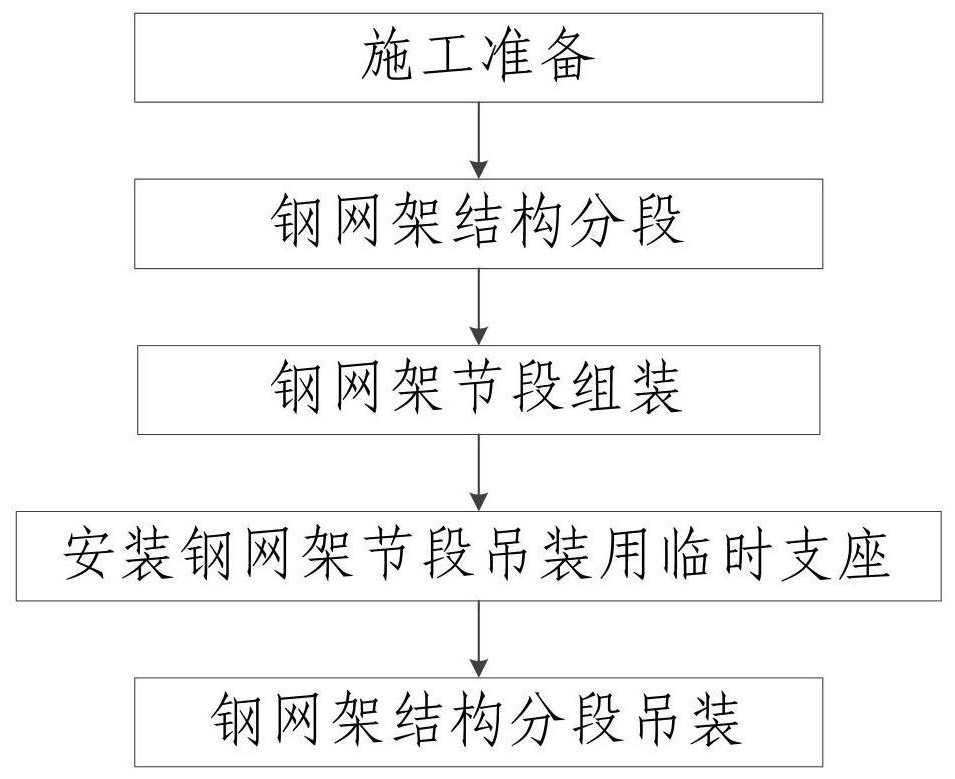

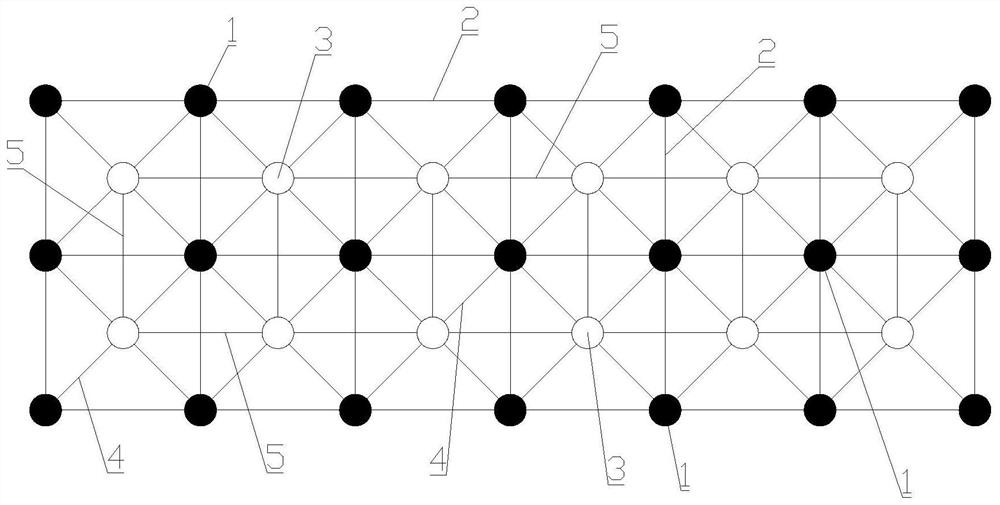

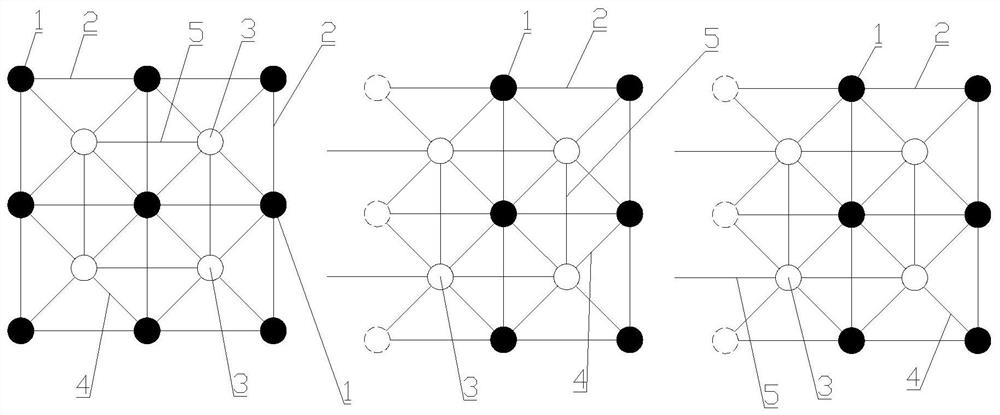

[0048] Such as Figure 1 to Figure 4 Shown is a segmental hoisting construction method of a steel grid structure, the steel grid structure to be hoisted includes a lower grid and an upper grid arranged above the lower grid, and the lower grid and the upper grid are parallel to each other , the lower grid and the upper grid are single-layer grid structures assembled from a plurality of rectangular unit grids, and each of the rectangular unit grids is assembled from four string balls and string rods. The string ball in the grid frame is the lower string ball 1, the string bar in the lower layer grid frame is the lower string bar 2, the string ball in the upper layer grid frame is the upper string ball 3, and the string bar in the upper layer grid frame is the upper string bar 5. An upper string ball 3 is arranged directly above each rectangular unit grid in the grid, and each upper string ball 3 is connected with four lower string balls 1 in the rectangular unit grid directly be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com