High-defect cobaltosic oxide catalyst for catalytic oxidation of formaldehyde as well as preparation method and application thereof

A tricobalt tetroxide catalyst and technology of tricobalt tetroxide, applied in the direction of metal/metal oxide/metal hydroxide catalyst, cobalt oxide/cobalt hydroxide, physical/chemical process catalyst, etc., can solve the problem of high price of precious metals, easy deactivation and wide use problems, to achieve the effect of large specific surface area, excellent formaldehyde catalytic oxidation performance, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Flake Co 3 o 4 preparation of

[0032] 40ml 0.5 mol / L Co(NO 3 )·6H 2 O and 1mol / L ammonia water are dropped into 300ml deionized water at 60°C at the same time to keep the pH value at 7-9. After the addition, continue to stir and age for 1h, centrifuge to obtain a precipitate, wash until neutral, and bake in an oven at 60°C for 12h. Baked at 300°C for 3 hours in a muffle furnace to obtain flake cobalt tetroxide (Co 3 o 4 ).

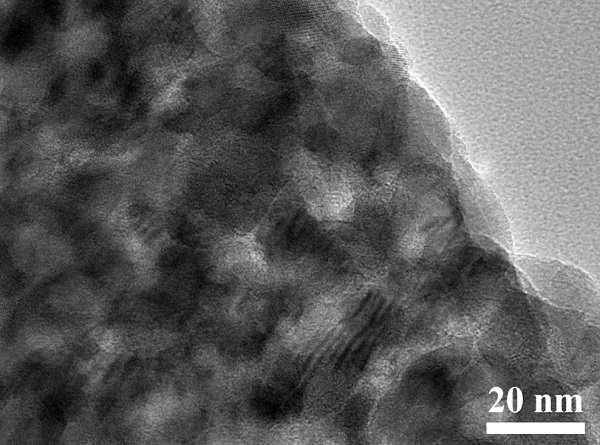

[0033] figure 1 For the Co prepared in Example 1 3 o 4 TEM image of figure 1 Shows Co 3 o 4 shape of the nanosheets.

Embodiment 2

[0034] Example 2 High-defect flake cobalt tetroxide catalyst H-Co for catalytic oxidation of formaldehyde 3 o 4 preparation of

[0035] 0.2g of the Co prepared in Example 1 3 o 4 Dissolve in 60mL of 4mol / L hydrochloric acid solution, stir for 3h, wash with a large amount of deionized water to pH = 7, and dry overnight in an oven at 60°C to obtain highly defective tricobalt tetroxide (H-Co 3 o 4 ).

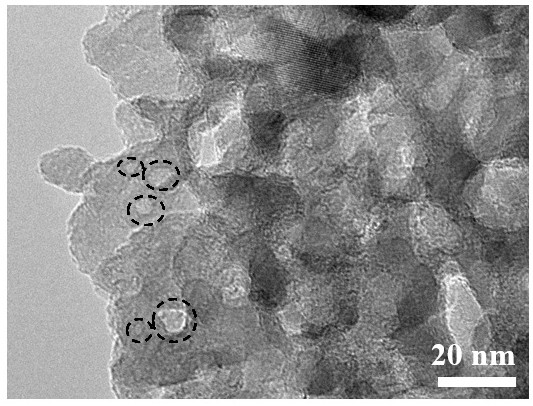

[0036] figure 2 For the H-Co prepared in Example 2 3 o 4 TEM image of figure 2 It shows that many small holes appear on the surface of the material after pickling treatment, which proves that the exposed surface increases after pickling.

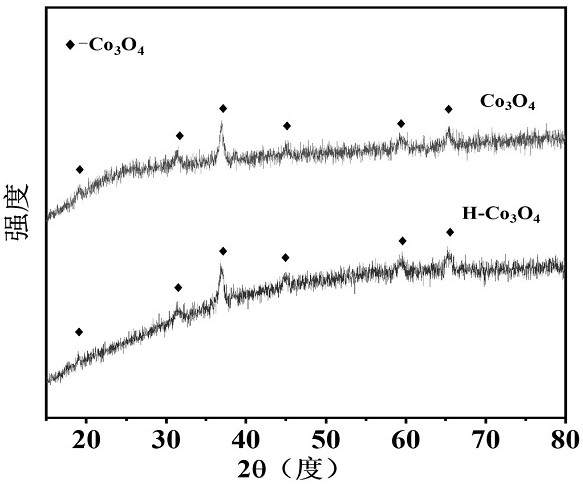

[0037] image 3 For the Co prepared in Example 1 3 o 4 And the H-Co that embodiment 2 prepares 3 o 4 The XRD spectrum, from image 3 It can be seen that the crystal phase of the flaky cobalt trioxide before and after pickling has not changed.

[0038] Figure 4 For the Co prepared in Example 1 3 o 4 And the H-Co that embodiment...

Embodiment 3

[0042] Example 3 Cobalt Tetroxide Catalyst H-Co for Catalytic Oxidation of Formaldehyde 3 o 4 Catalytic Oxidation of Formaldehyde

[0043] 0.1 g of the catalysts in Examples 1-2 were used respectively, and were loaded into a fixed-bed reactor at a mass space velocity of 100,000 mL / g / h to measure the conversion rate of formaldehyde, and the concentration of formaldehyde in the tail gas was determined by gas chromatography. The composition of the reflected gas is: 2% formaldehyde, 20% oxygen, and nitrogen as the balance gas. The conversion effect of the catalyst on formaldehyde was measured at 20-250°C, and the test results are shown in Figure 7 , at a space velocity of 100000 mL / g / h, the performance of the pickled material was significantly improved compared with that before treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com