Binary structure heat-not-burn smoke cartridge containing fragrance release carrier

A heat-not-burn, cartridge technology, used in tobacco, tobacco processing, cigar manufacturing, etc., can solve the problems of high flue gas temperature, single aroma release, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

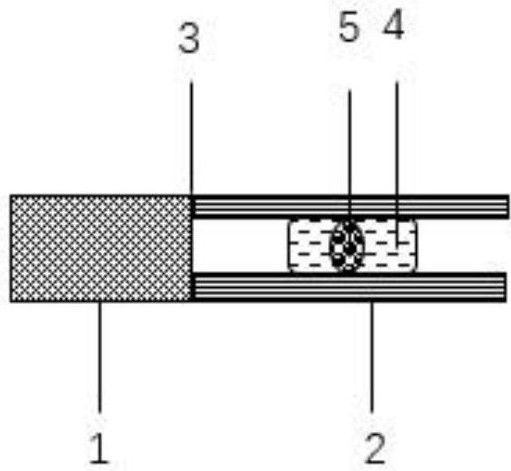

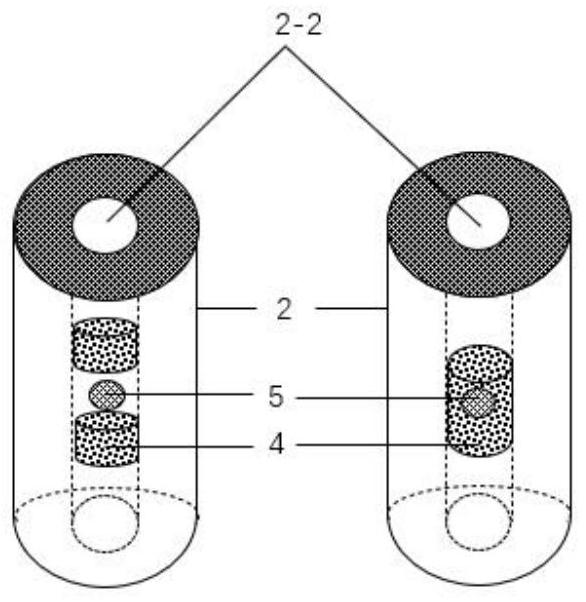

[0068] Example 1: The dual structure heat-not-burn pod of the present invention

[0069] The implementation mode of this embodiment is as follows:

[0070] The dual structure heat-not-burn pod of the present invention is formed by sequentially wrapping and connecting the smoke-generating section and the smoke-binding section through the outer wrapping paper. Its length is 42mm and its diameter is 7.5mm.

[0071] The smoking section is made of flake-shaped smoking material, which consists of 75 parts by weight of mint plant superfine powder, 2.5 parts by weight of guar gum binder, 21 parts by weight of glycerin smoker and 0.25 parts by weight of It consists of 1 part peppermint oil volatile essence, and the length of the smoking section is 8mm.

[0072] The smoke confinement section is a cylinder made of silica gel material with a water content of 2.3% by weight by injection molding; the side of the cross section of the smoke confinement section is circular; A through hole pa...

Embodiment 2

[0076] Example 2: The dual structure heat-not-burn pod of the present invention

[0077] The implementation mode of this embodiment is as follows:

[0078] The dual structure heat-not-burn pod of the present invention is formed by sequentially wrapping and connecting the smoke-generating section and the smoke-binding section through the outer wrapping paper. Its length is 20mm and its diameter is 5.3mm.

[0079] The smoking section is composed of granular smoking material, which consists of 65 parts by weight of flue-cured tobacco plant superfine powder, 2.1 parts by weight of sodium carboxymethyl cellulose binder, and 25 parts by weight of glycerol smoking agent Composed of 0.1 parts by weight of tobacco absolute volatile essence, the length of the smoking section is 12mm.

[0080] The smoke confinement section is a cylinder made of polylactic acid material with a water content of 2.0% by weight by extrusion; the side of the cross section of the smoke confinement section is ...

Embodiment 3

[0083] Example 3: A heat-not-burn pod with a binary structure of the present invention

[0084] The implementation mode of this embodiment is as follows:

[0085] The dual-structure heat-not-burn pod of the present invention is formed by wrapping and connecting the smoke-generating section and the smoke-binding section sequentially through the outer wrapping paper. Its length is 50mm and its diameter is 8.0mm.

[0086] The smoking section is composed of a paste-like smoking material, which consists of 72 parts by weight of betel nut plant superfine powder, 1.8 parts by weight of chitosan and guar gum mixed binder, 27 parts by weight of glycerin diacetate The ester fuming agent is composed of 1.4 parts by weight of the volatile essence of betel nut extract, and the length of the fuming section is 20mm.

[0087] The smoke confinement section is a cylinder made of polypropylene material with a water content of 4.0% by weight by injection molding; the side of the cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com