Steel coil tail and steel coil ID automatic identification structure and method

An automatic identification and steel coil technology, applied in character and pattern recognition, computer parts, instruments, etc., can solve the problems of large manual workload, low production efficiency, mixed steel production, etc., achieve simple maintenance and improve production efficiency , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose and technical solutions of the specific embodiments of the present invention clearer, the technical solutions of the specific embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings and the implementation examples of the specific embodiments of the present invention. Obviously, the described embodiments are some, but not all, embodiments of the present invention.

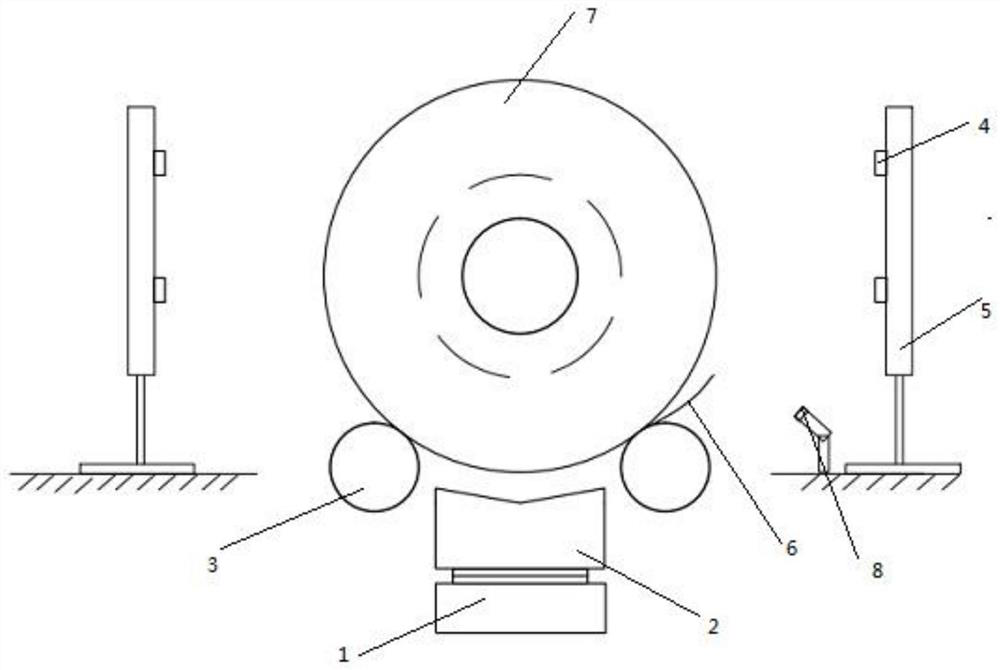

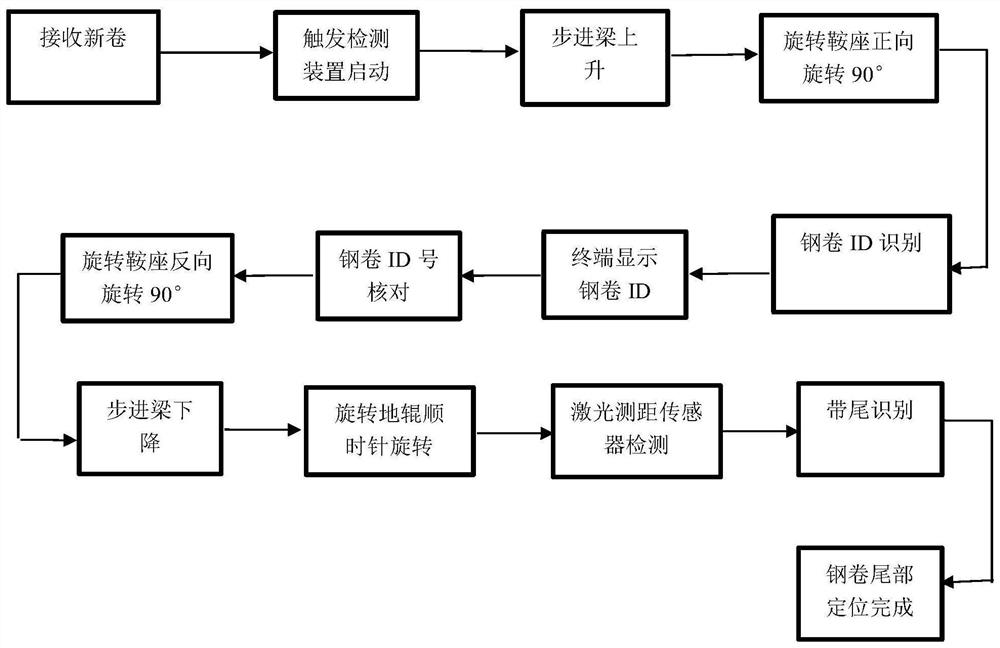

[0029] like figure 1 As shown in the figure, a structure for automatic identification of steel coil tail and steel coil ID includes a walking beam 1, a rotating saddle 2 arranged above the walking beam, and a set of rotating ground roller saddles 3, and the walking beam 1 is controlled by a control system Control, the control system is provided with a grating detector, the rotating saddle 2 is connected with the hydraulic motor provided, the rotating floor roller saddle 3 is arranged above the rotating saddle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com