Preparation method and application of flame-retardant coated fabric based on graphene oxide

A graphene and coating technology, used in flame-retardant fibers, plant fibers, textiles and papermaking, etc., can solve problems such as limited small-scale applications, and achieve reliable fire detection, good flexibility, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation method of graphene oxide / PDMAEMA / hexagonal boron nitride sandwich layered nano-coating flame-retardant cotton fabric comprises the following steps:

[0050] (1) Slowly add a mixed solution of concentrated sulfuric acid (90mL) and phosphoric acid (10mL) into a flask containing graphite (0.75g) and potassium permanganate (4.5g), stir at 50°C for 12h, and pour the solution Put 200g of 30% hydrogen peroxide (0.75mL) into an ice-bath environment, cool to room temperature, and centrifuge with 50mL of water, 30% hydrochloric acid solution, 50mL of ethanol at 4000rpm for 4h to obtain a suspension, filter it, and vacuum-dry overnight at room temperature Obtain pure graphene oxide;

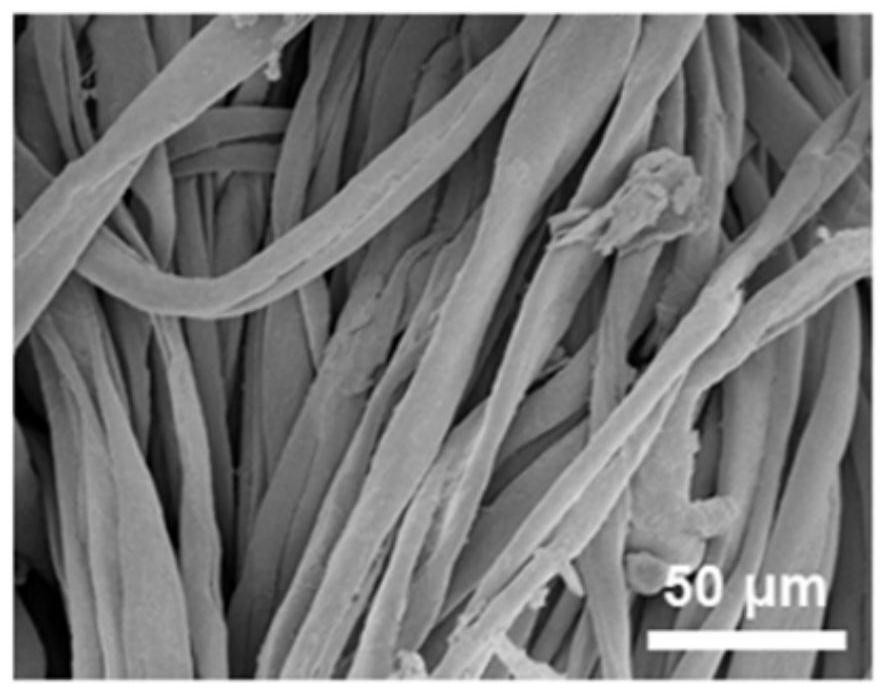

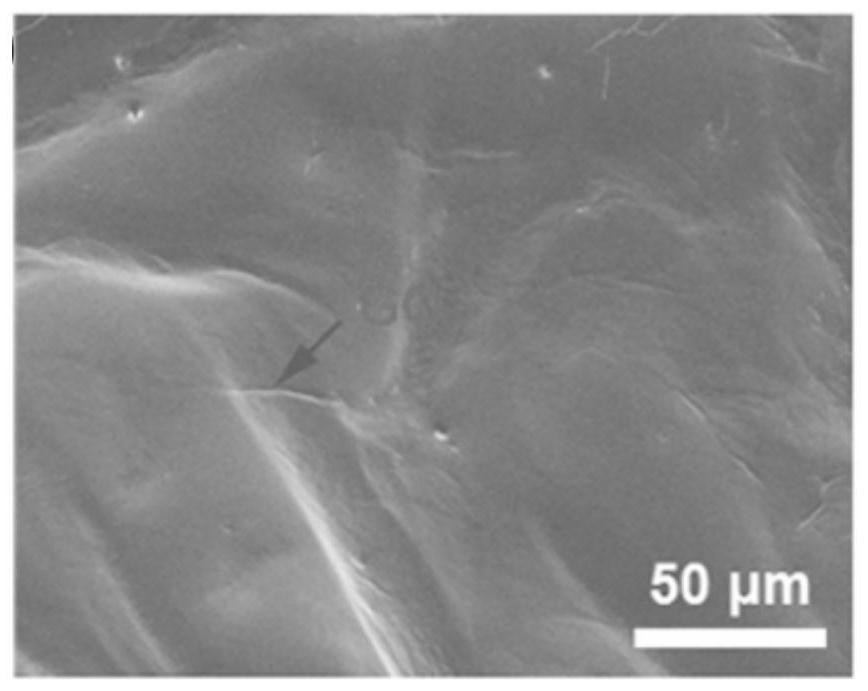

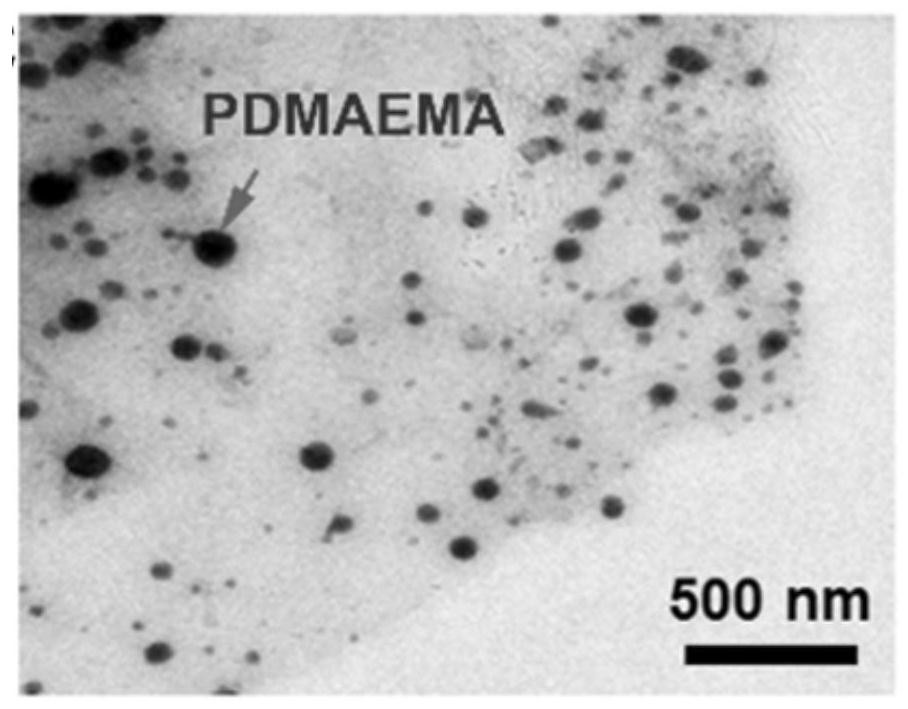

[0051] (2) Soak the cotton fabric after washing with water and ethanol in the graphene oxide aqueous dispersion with a concentration of 1 mg / mL for t 1 After the time (30min), dry at room temperature (the same soaking method is repeated 3 times in total), obtain graphene oxide coated...

Embodiment 2

[0060] The preparation method of graphene oxide / PDMAEMA / hexagonal boron nitride sandwich layered nano-coating flame-retardant cotton fabric comprises the following steps:

[0061] (1) Slowly add a mixed solution of concentrated sulfuric acid (90mL) and phosphoric acid (10mL) into a flask containing graphite (0.75g) and potassium permanganate (4.5g), stir at 50°C for 12h, and pour the solution Put 200g of 30% hydrogen peroxide (0.75mL) into an ice-bath environment, cool to room temperature, and centrifuge with 50mL of water, 30% hydrochloric acid solution, 50mL of ethanol at 4000rpm for 4h to obtain a suspension, filter it, and vacuum-dry overnight at room temperature Obtain pure graphene oxide;

[0062] (2) Soak the cotton fabric after washing with water and ethanol in the graphene oxide aqueous dispersion with a concentration of 0.5 mg / mL for t 1 After a time (50 min), dry at room temperature, and repeat the same soaking method 3 times to obtain a graphene oxide-coated cotto...

Embodiment 3

[0067] The preparation method of graphene oxide / PDMAEMA / hexagonal boron nitride sandwich layered nano-coating flame-retardant cotton fabric comprises the following steps:

[0068] (1) Slowly add a mixed solution of concentrated sulfuric acid (90mL) and phosphoric acid (10mL) into a flask containing graphite (0.75g) and potassium permanganate (4.5g), stir at 50°C for 12h, and pour the solution Put 200g of 30% hydrogen peroxide (0.75mL) into an ice-bath environment, cool to room temperature, and centrifuge with 50mL of water, 30% hydrochloric acid solution, 50mL of ethanol at 4000rpm for 4h to obtain a suspension, filter it, and vacuum-dry overnight at room temperature Obtain pure graphene oxide;

[0069] (2) Soak the cotton fabric after washing with water and ethanol in the graphene oxide aqueous dispersion that concentration is 1.5mg / mL 1 After time (20 min), dry at room temperature, and repeat the same soaking method 5 times to obtain a graphene oxide-coated cotton fabric; w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com