Unidirectional moisture-conducting fabric and preparation method thereof

A technology of moisture permeability and fabric, applied in the direction of non-woven fabrics, textiles and papermaking, conjugated synthetic polymer artificial filaments, etc., can solve the problems of undisclosed fabrics, unexplained, etc., achieve excellent air permeability, and improve wearing comfort , Improve the effect of water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of PVA / SA spinning solution

[0032] Dissolve 10 g of PVA in 90 g of deionized water, swell at room temperature for 12 h, mechanically stir at 90° C. for 3 h, and cool to room temperature to obtain a 10 wt % PVA solution. 3g of SA was dissolved in 97g of deionized water at 60°C for 3h to obtain a 3wt% SA solution. Then mechanically stirred, the PVA and SA solutions were mixed at 9:1 (v / v), and SDS (0.1115g / 50mL) surfactant was added to obtain an electrospinning solution.

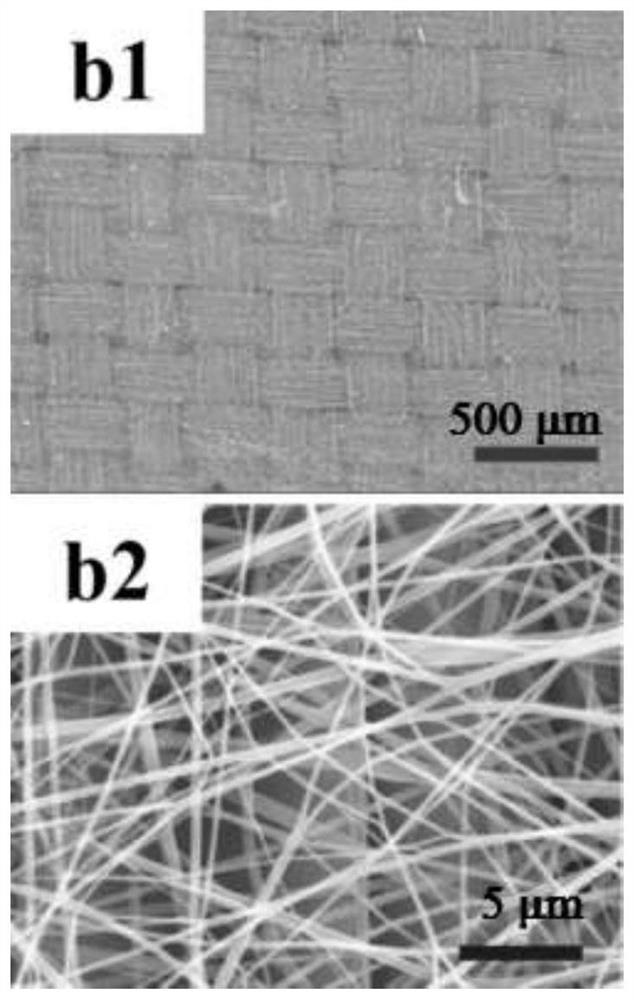

[0033] 2. Preparation of Pretreated Fabrics

[0034] The polyester fabric was cut into 40cm×17cm, the thickness of polyester was 60μm, and the polyester was treated with 10wt% CaCl 2 Soak in the solution for 20 minutes, suspend until there is no droplet, and then fix it on the rotating collector of the electrospinning machine. The rotational speed of the collector was 100 rpm.

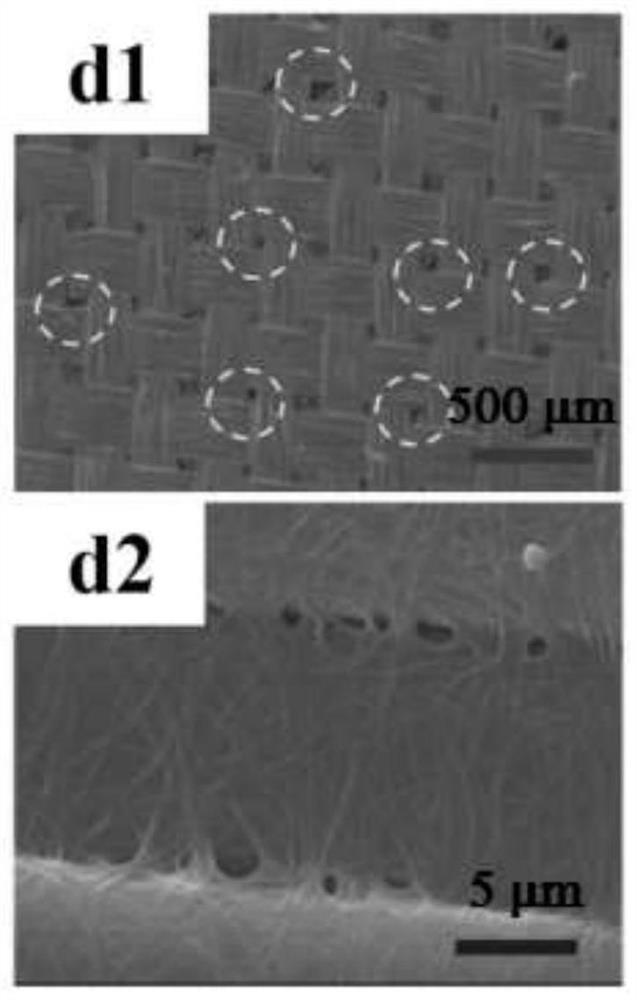

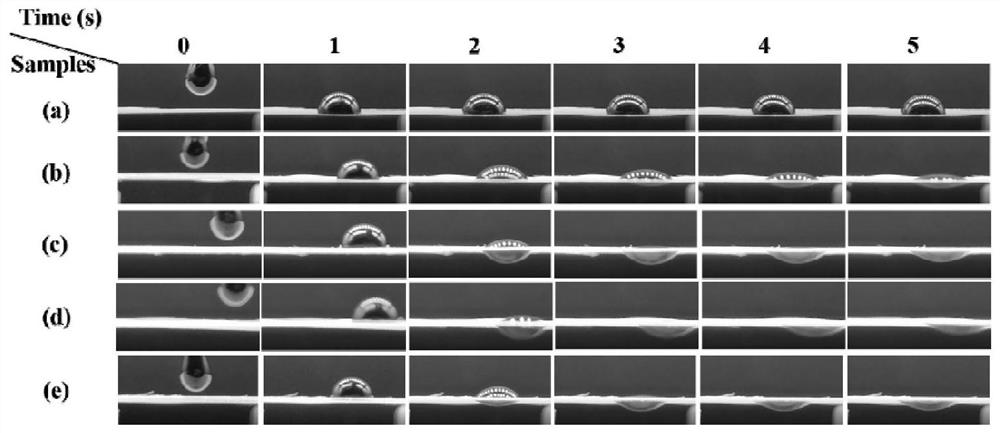

[0035] 3. Preparation of Unidirectional Moisture-permeable Fabric

[0036]The electrospinning solution w...

Embodiment 2

[0038] Same as Example 1, the difference is that CaCl 2 The solution concentration is 5 wt%.

Embodiment 3

[0040] Same as Example 1, the difference is that CaCl 2 The solution concentration is 15 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com