Preparation method of surfactant for oil displacement

A surfactant and oil displacement technology, applied in the field of surfactant preparation, can solve the problems of inability to effectively improve oil recovery, poor compatibility of surfactants, large interfacial tension, etc., and achieve good emulsification and viscosity reduction effect, The effect of improving oil displacement efficiency and low interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

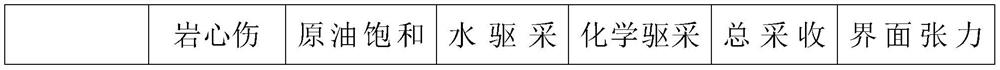

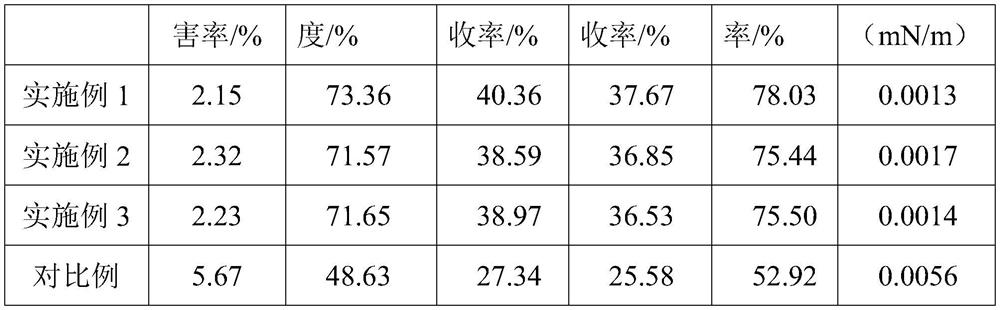

Examples

Embodiment 1

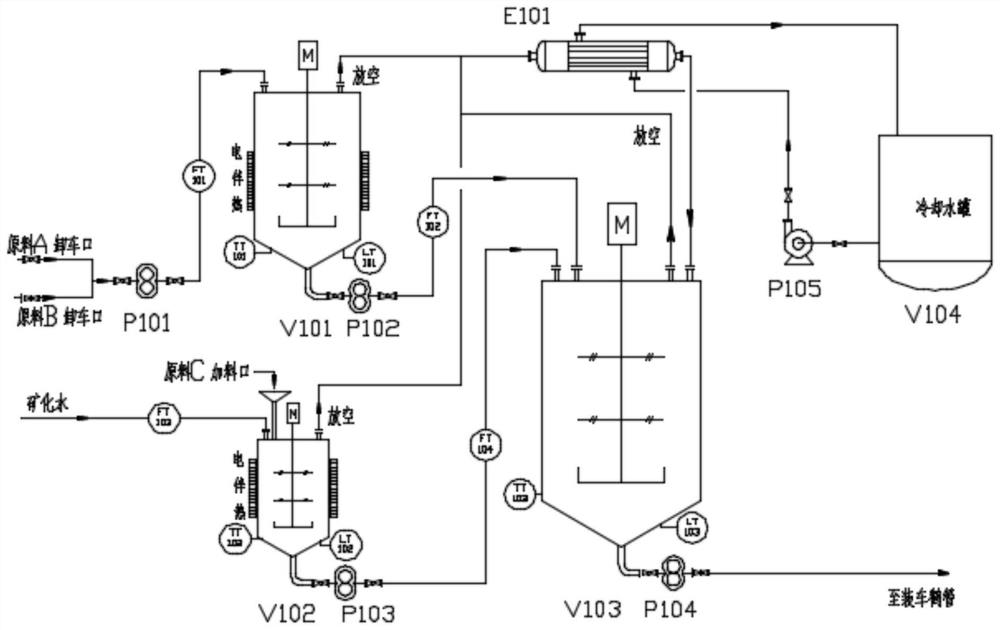

[0033] A preparation method of surfactant for oil displacement, comprising the following steps:

[0034] S1. After measuring the raw material A and raw material B by a floor scale according to a certain ratio, the raw material A with a lower viscosity is first transported to the preparation tank V101 through the raw material feeding pump P101, and then the raw material B with a slightly higher viscosity is transported to the preparation tank In V101, when the liquid level in the tank reaches 45%, start the agitator, and when the material liquid level reaches the highest liquid level in the mixing tank V101, continue stirring for 25 minutes for standby;

[0035] S2. Calculate the relationship between the liquid level and weight of the dissolution tank according to the volume and height of the dissolution tank; then open the inlet pipeline valve of the mineralized water in the dissolution tank V102, start the deep well water submersible pump, and pump the mineralized water into t...

Embodiment 2

[0050] A preparation method of surfactant for oil displacement, comprising the following steps:

[0051] S1. After measuring the raw material A and raw material B by a floor scale according to a certain ratio, the raw material A with a lower viscosity is first transported to the preparation tank V101 through the raw material feeding pump P101, and then the raw material B with a slightly higher viscosity is transported to the preparation tank In V101, when the liquid level in the tank reaches 50%, start the agitator, and when the material liquid level reaches the highest liquid level in the mixing tank V101, continue stirring for 30 minutes for standby;

[0052] S2. Calculate the relationship between the liquid level and weight of the dissolution tank according to the volume and height of the dissolution tank; then open the inlet pipeline valve of the mineralized water in the dissolution tank V102, start the deep well water submersible pump, and pump the mineralized water into t...

Embodiment 3

[0067] A preparation method of surfactant for oil displacement, comprising the following steps:

[0068] S1. After measuring the raw material A and raw material B by a floor scale according to a certain ratio, the raw material A with a lower viscosity is first transported to the preparation tank V101 through the raw material feeding pump P101, and then the raw material B with a slightly higher viscosity is transported to the preparation tank In V101, when the liquid level in the tank reaches 55%, start the agitator, and when the material liquid level reaches the highest liquid level in the mixing tank V101, continue stirring for 35 minutes for standby;

[0069] S2. Calculate the relationship between the liquid level and weight of the dissolution tank according to the volume and height of the dissolution tank; then open the inlet pipeline valve of the mineralized water in the dissolution tank V102, start the deep well water submersible pump, and pump the mineralized water into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com