Pin wheel housing gear milling tool

A pin gear housing and tooling technology, which is applied in the direction of manufacturing tools, planer/slotting machines, metal processing equipment, etc., can solve the problems of uneven distribution of half holes and affect the accuracy of half holes of pin gear housings, and achieve no jamming and smooth operation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

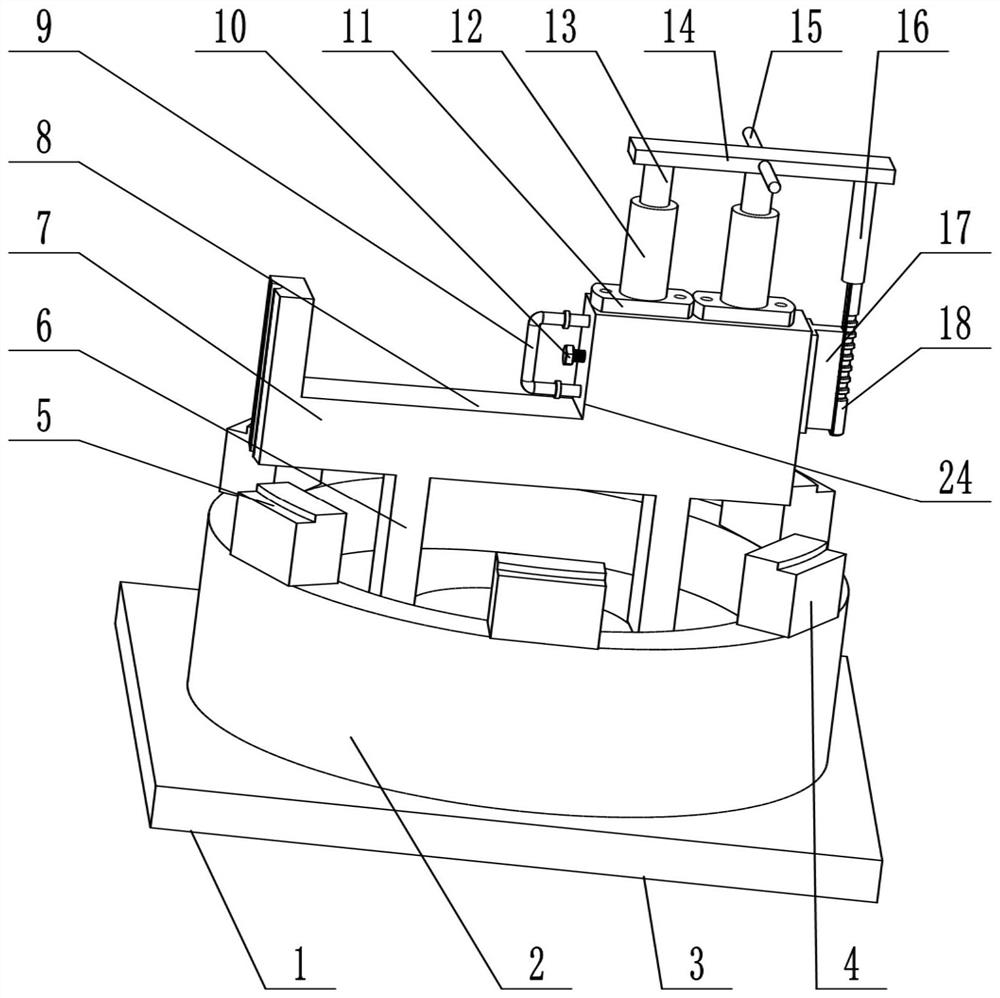

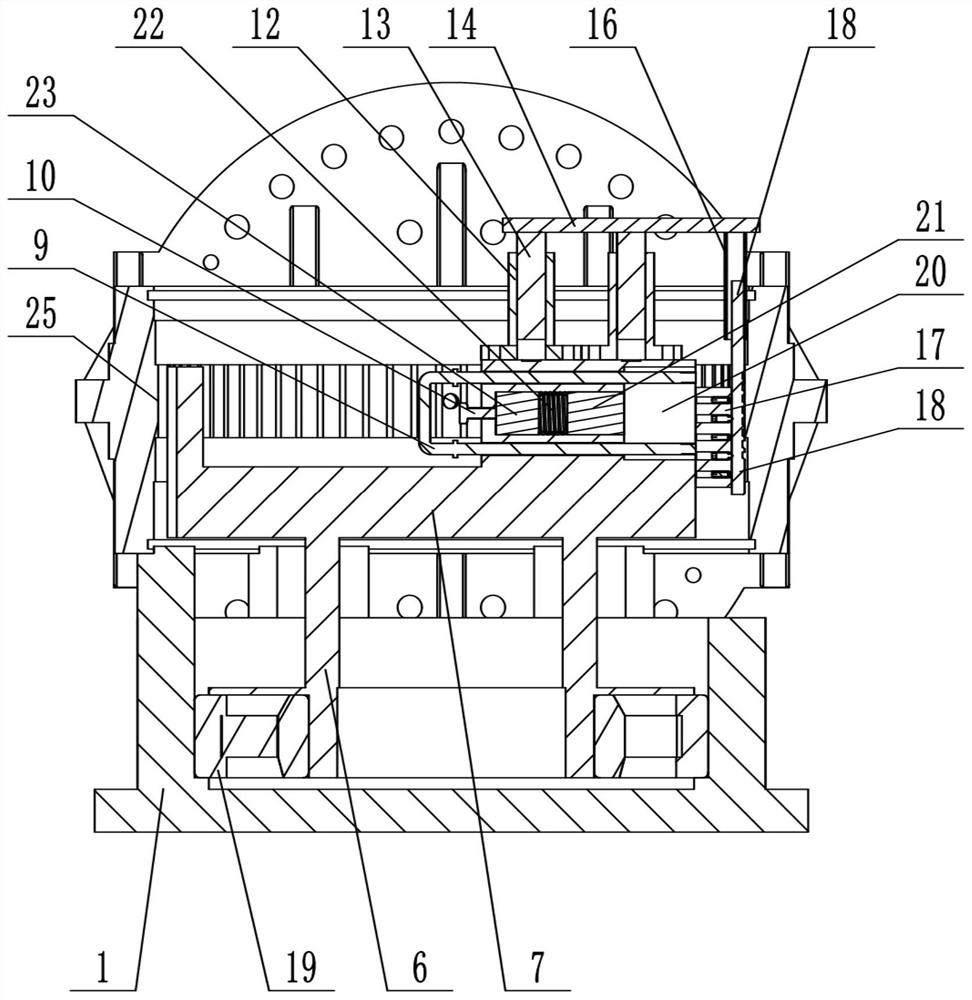

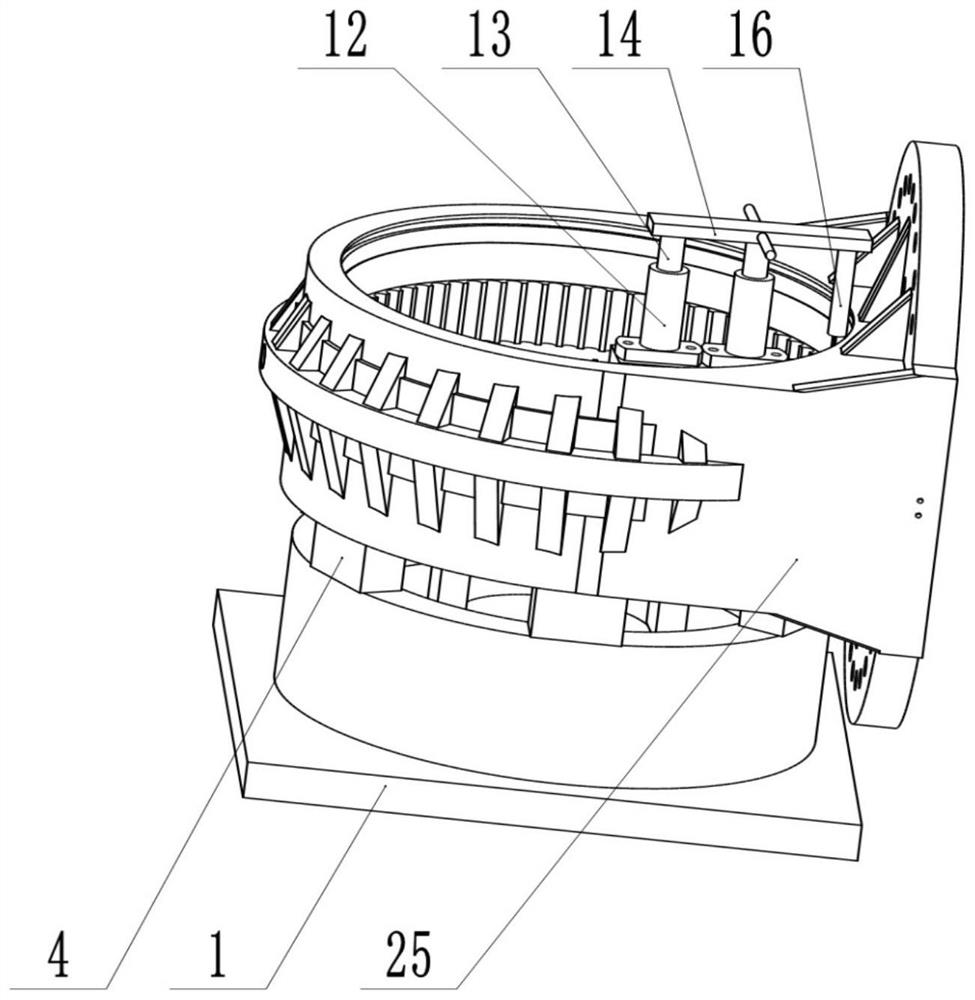

[0017] A pin gear housing tooling, comprising a pin gear housing support seat 1 for placing a pin gear housing 25 and a tooth shaping rotation base 7, the pin gear housing 25 is placed on the pin gear housing support base 1, and the pin gear housing support base 1 The bottom of the inner side is provided with a rotary bearing 19, and the gear-shaping rotary base 7 is connected to the pin gear housing support seat 1 through the rotary bearing 19. The upper part of the gear-shaping rotary base 7 is provided with a notch groove 8, and the tooth-shaping rotary base 7 is provided with a notch groove 8. On the remaining notch groove wall 24, a sliding groove is horizontally extended from the outer sidewall to the inside, and a moving block 20 is slidably arranged on a side close to the opening end in the sliding groove, and a pusher is connected to the side wall of the moving block 20 towards the outside of the opening end. Knife extrusion plate 17, the inboard of moving block 20 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com