Reversing-valve unloading pushrod device used under coal mine

A technology of a push rod device and a reversing valve, which is applied in the directions of transportation and packaging, railway car body parts, railway braking systems, etc., and can solve the problems of inconvenient disassembly and replacement, lack of safety guarantee, inconvenient switching, opening and reversing Valve and other problems, to achieve the effect of no jamming, safe and reliable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

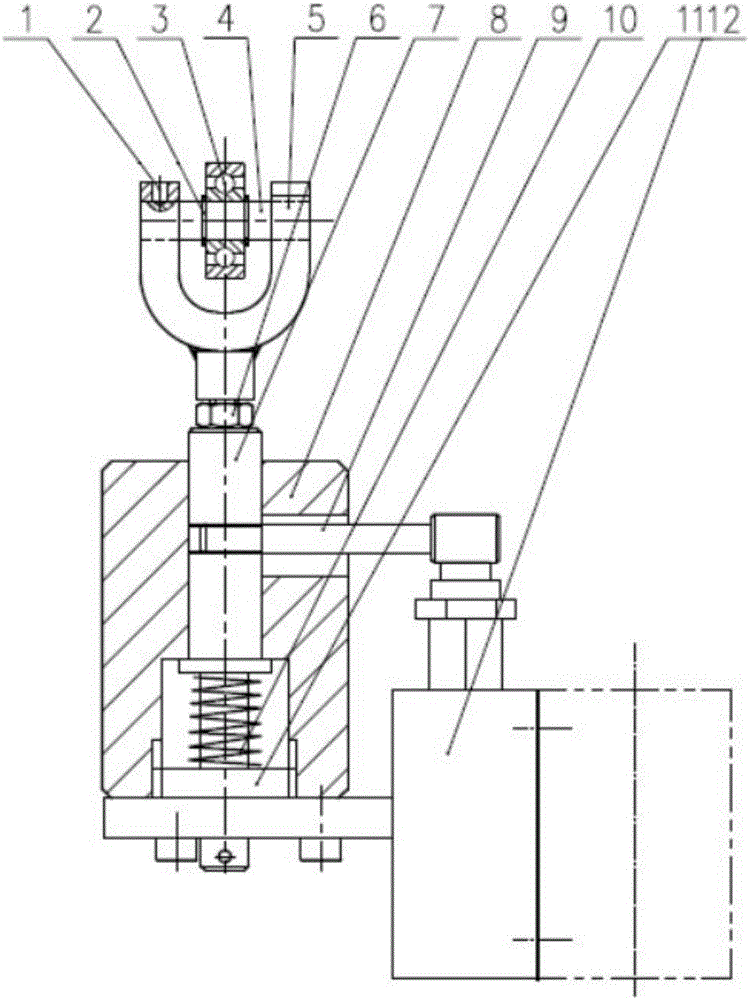

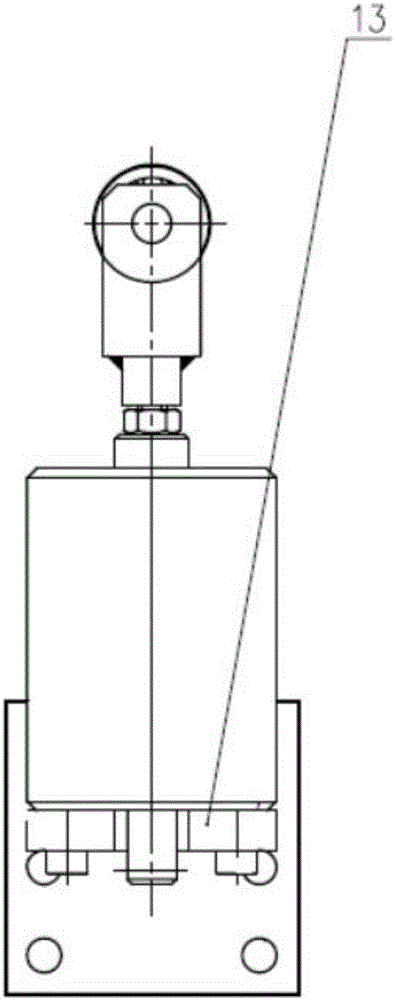

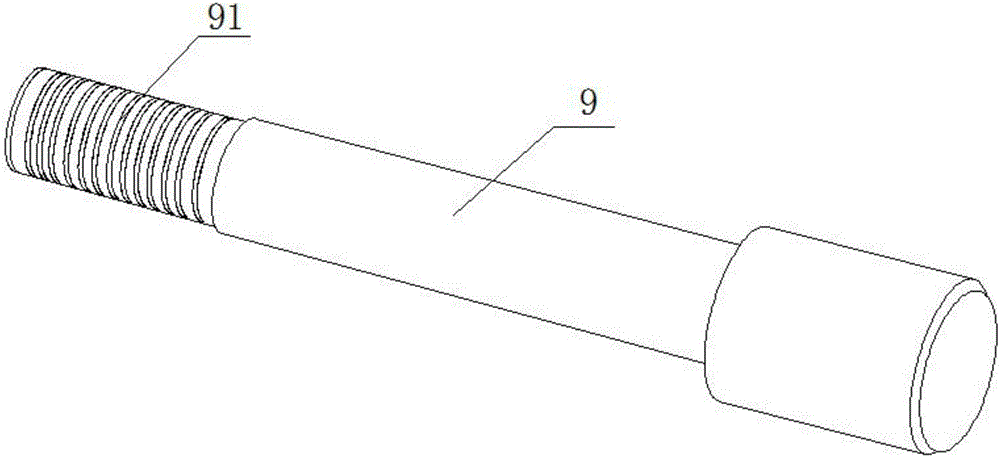

[0019] Such as Figure 1-4 As shown, the present invention provides a reversing valve unloading push rod device for underground coal mines, including a yoke seat 5, and a shaft circlip 2 and a deep groove ball bearing 3 are provided at the fork of the yoke seat 5 , and the circlip 2 for the shaft and the deep groove ball bearing 3 pass through the pin shaft 4 and are installed on the yoke seat 5, and the pin shaft 4 is axially fixed by the screw 1; the yoke seat 5 The bottom end is threadedly connected to the slide bar 7, and the bottom end of the slide bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com