Synchronous gear driven torque-resistance moment self-adapting automatic gear shift speed variator

A technology for driving torque and synchronizing gears, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., it can solve the problems of engine or motor torque - small speed change, high transmission efficiency, limited bearing torque, etc. The effect of smooth gear and running process, improved transmission efficiency and smooth load change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

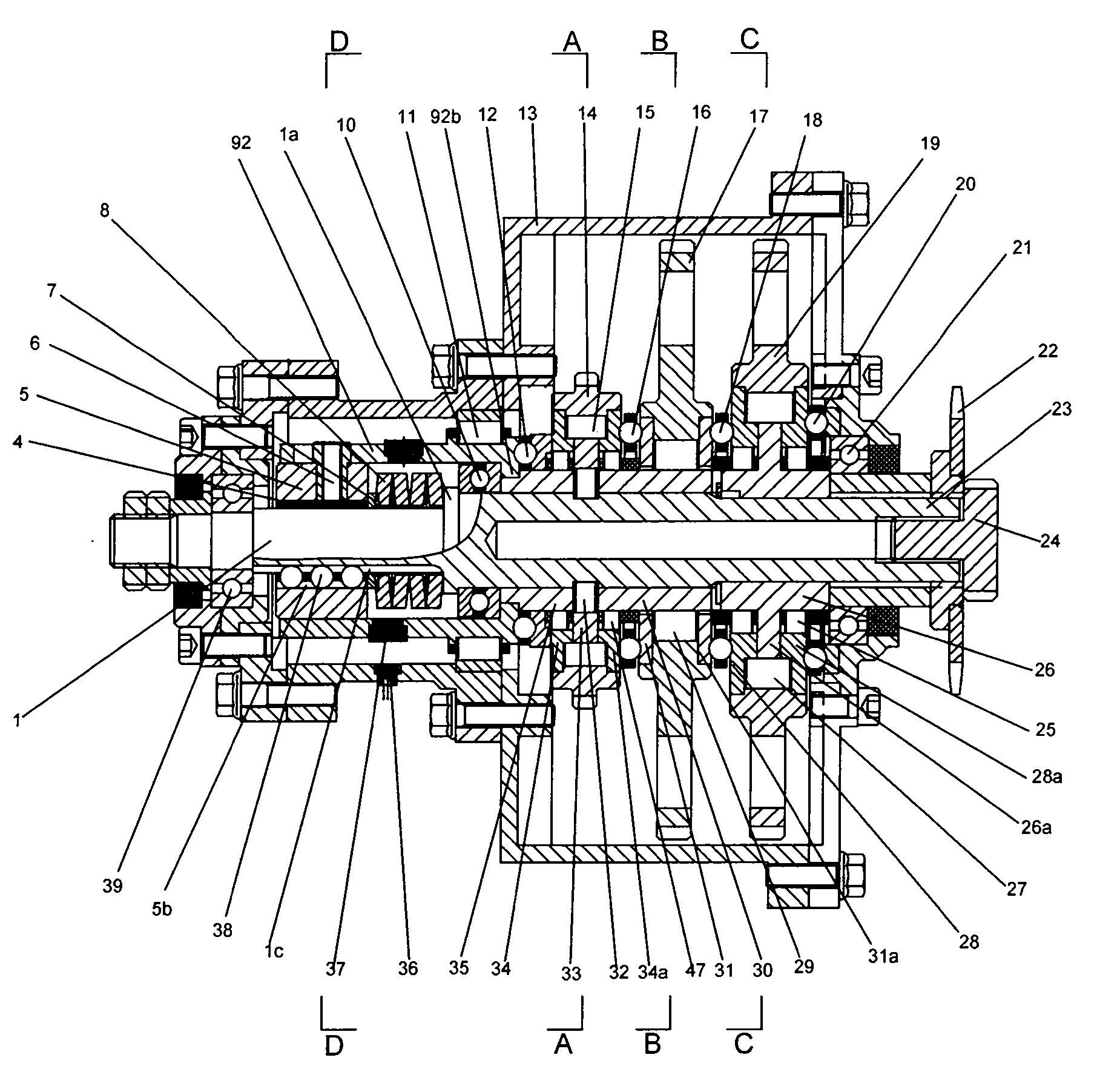

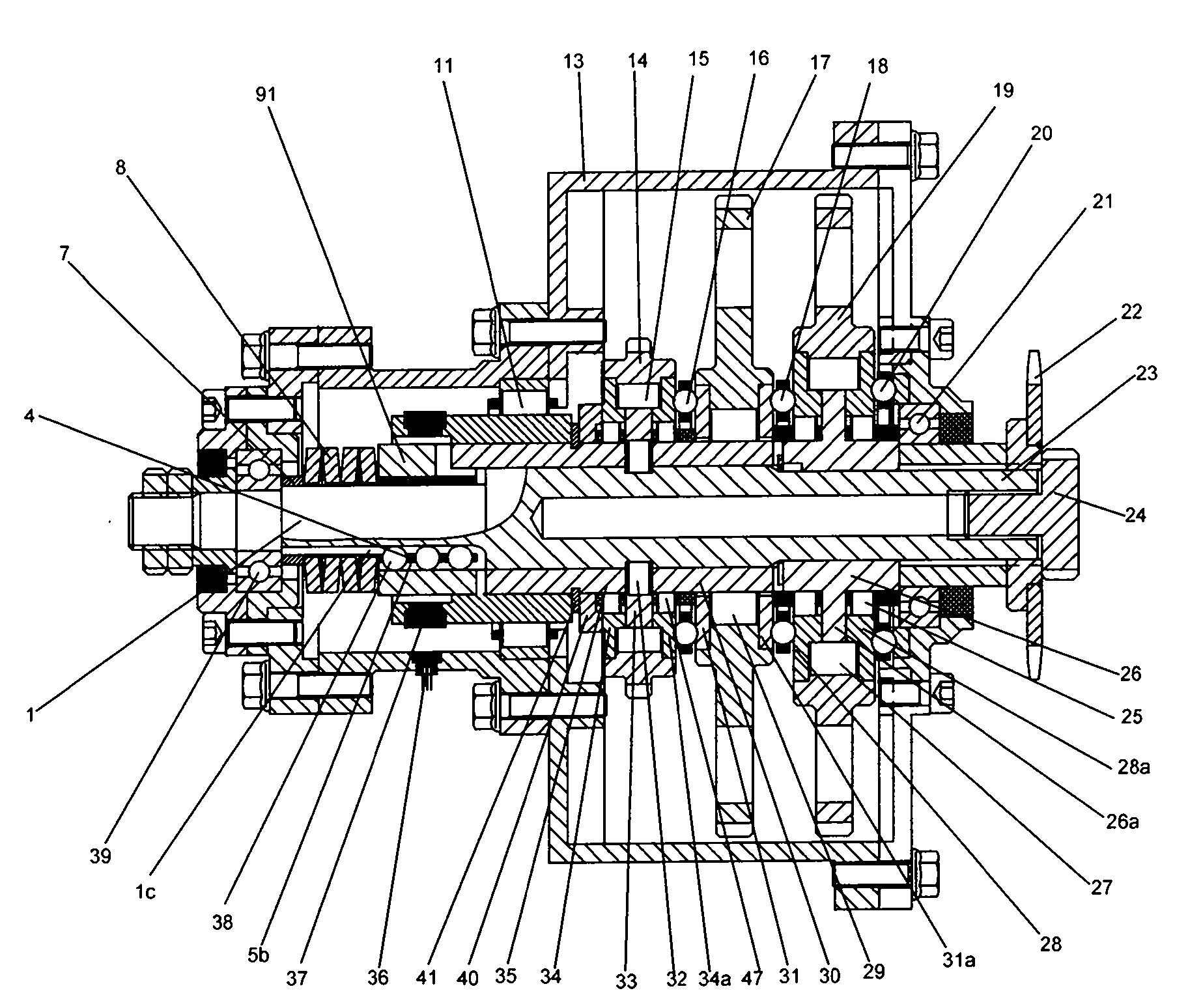

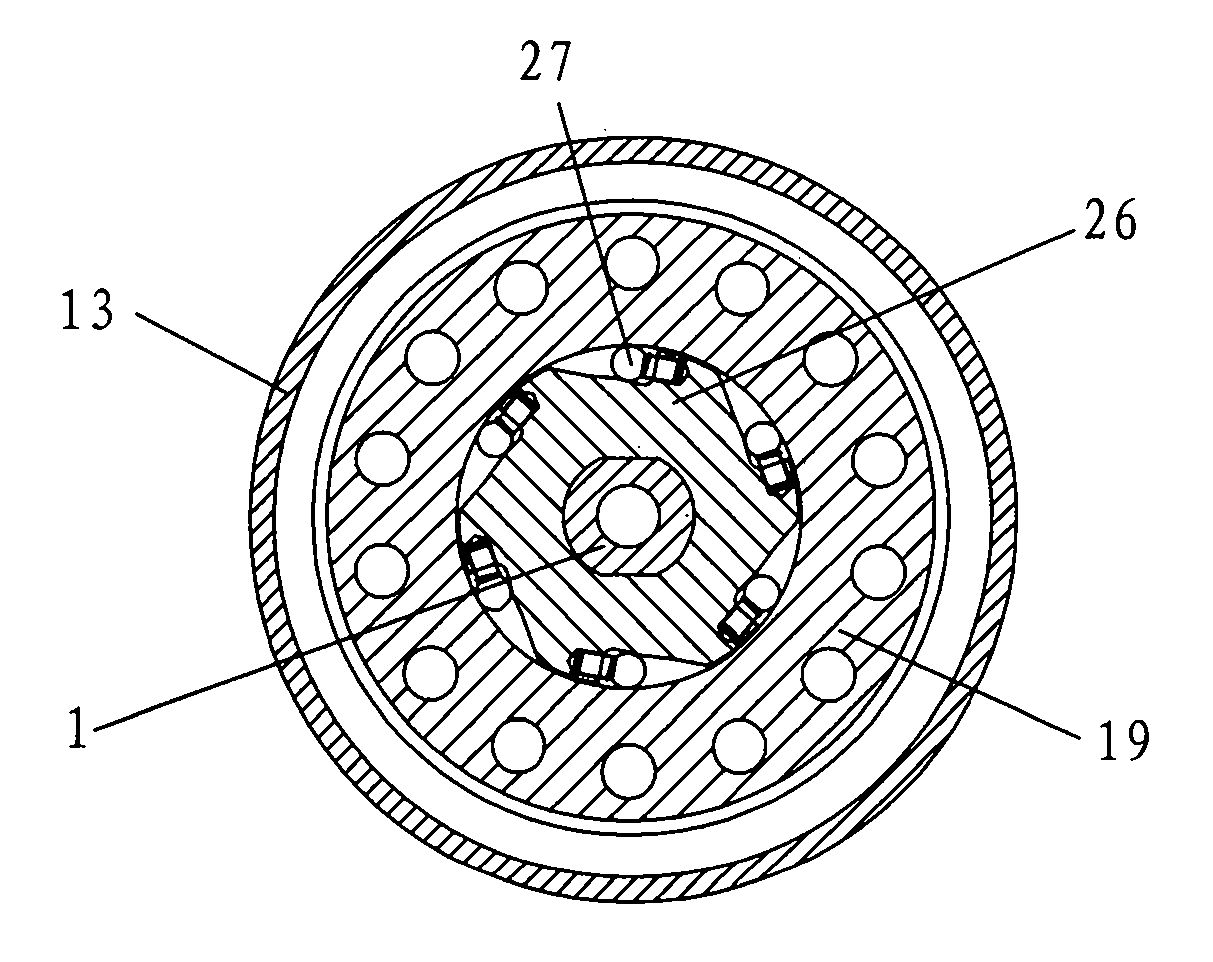

[0042] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the driven camshaft 1 of this embodiment rotates clockwise when viewed from right to left to right during operation. The motor is arranged outside the casing, and the two ends of the driven camshaft 1 are in rolling fit with the casing 13 through the second radial rolling bearing 39 and the third radial rolling bearing 21, and the inner ring of the third radial rolling bearing 21 is set on the On the driven camshaft 1 , the right end of the driven camshaft 1 protrudes from the casing 13 and the sprocket 22 is fixedly matched with the sprocket 22 through bolts 24 .

[0043] Such as figure 1 As shown, the synchronous gear driving torque-resistance torque adaptive automatic shift transmission of the present invention includes the fast gear cam ejector gear overrunning clutch and the slow gear overrunning clutch synchronous gear mechanism arranged on the driven camshaft 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com