Double-overrunning clutch mechanical type shaft sleeve output self-adaptive automatic speed changing electric driving system

An electric drive system and technology beyond clutch, applied in the direction of mechanical equipment, mechanical control device, control/regulation system, etc., to achieve the effect of smooth load change, reduced manufacturing cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

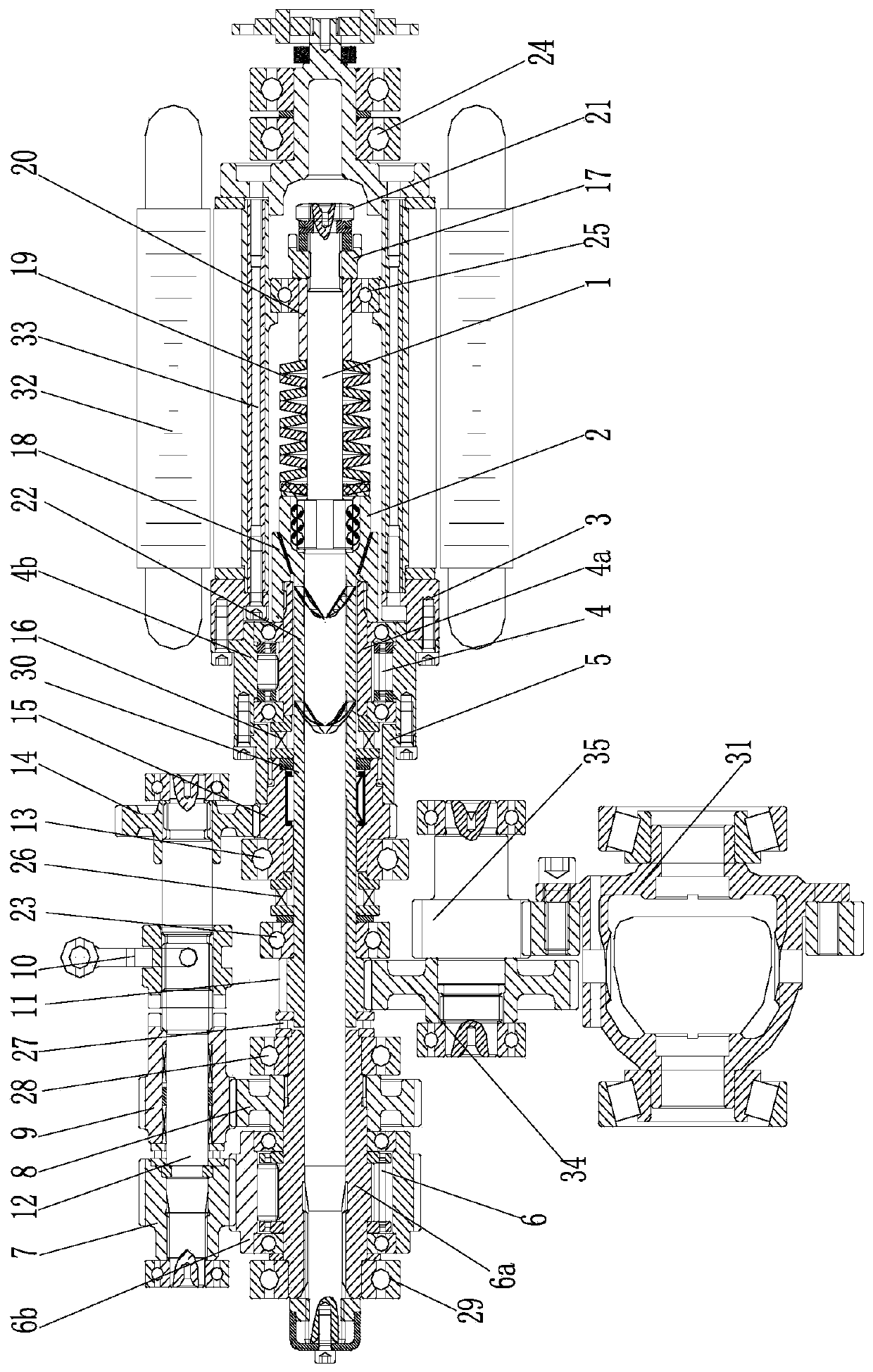

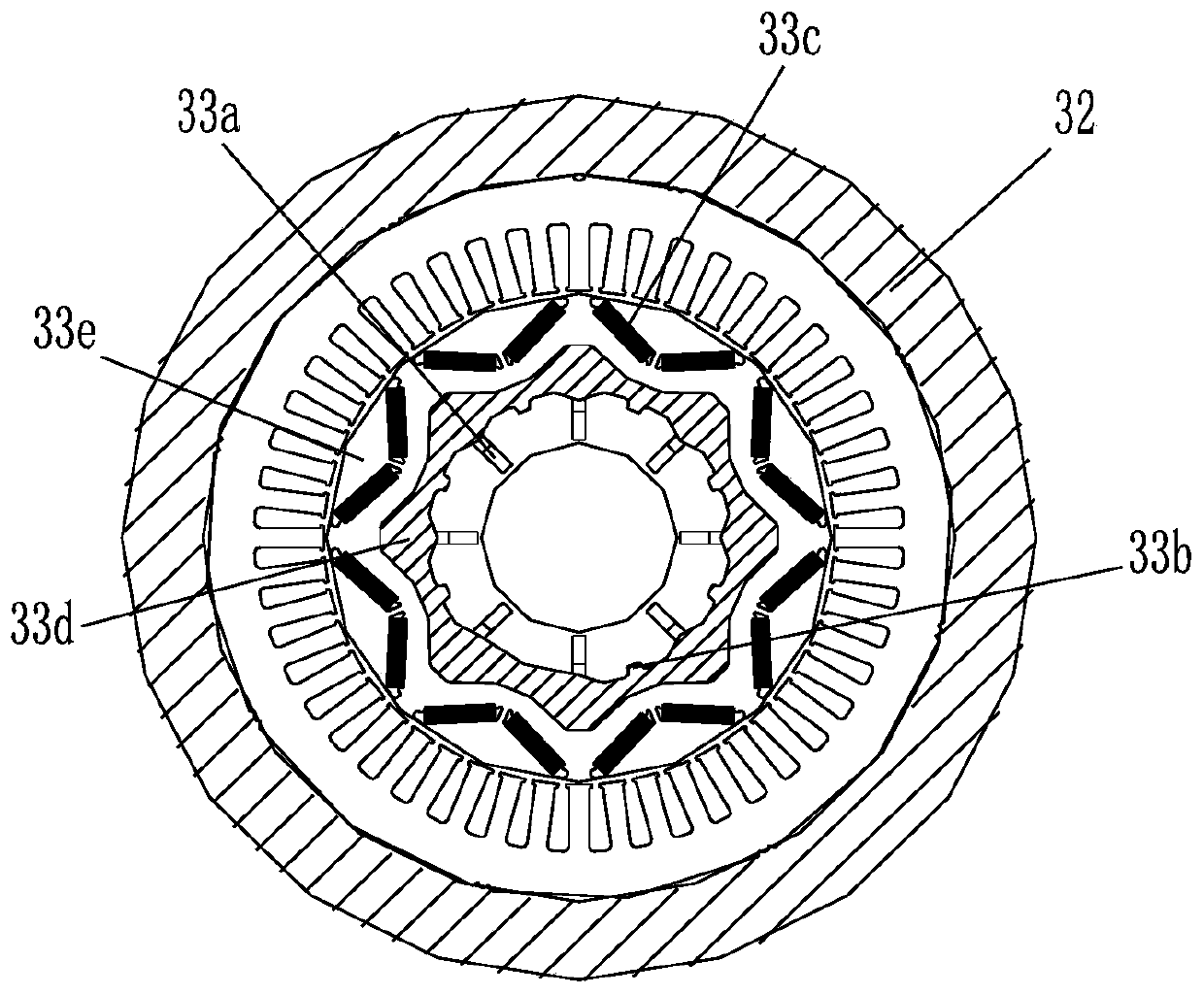

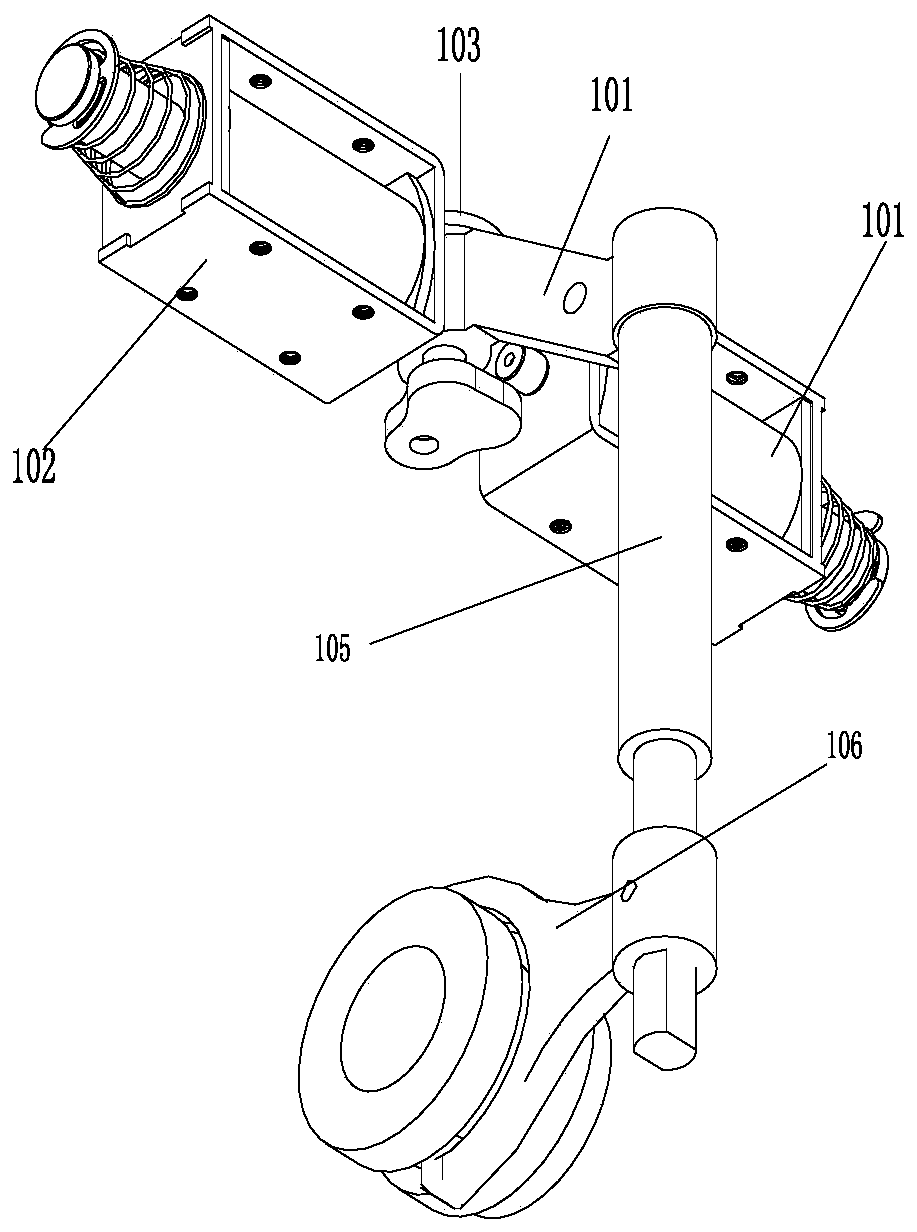

[0044] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 is the transverse section view of the drive motor, image 3 It is a schematic diagram of the electromagnetic shifting structure, Figure 4 The cross-sectional view of the position electromagnetic shifting structure is shown in the figure: the double overrunning clutch mechanical bushing output adaptive automatic variable speed electric drive system of the present invention includes a box body, a drive motor and a transmission, and the transmission includes a main shaft 1 and a main shaft 1 The speed change system and the power take-off bushing that is fitted on the main shaft in rotation, the speed change system includes a low gear transmission mechanism, a reverse gear transmission mechanism and an adaptive transmission assembly;

[0045] The adaptive transmission assembly includes an active friction piece, a driven friction piece and a variable speed elastic element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com