Shape memory polymer material for esophagus stent and its preparation and application method

A memory polymer and control method technology, applied in the field of polymer materials, can solve problems such as difficult implantation positions, precise adjustments, tissue thermal damage, etc., and achieve the effects of simple preparation process, high application prospects, and high tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] 5. Application of the shape memory polymer material made by the preparation method of the shape memory polymer material

[0082] Application of shape memory polymer materials in esophageal stents.

[0083] Embodiments of the present invention are as follows:

Embodiment 1

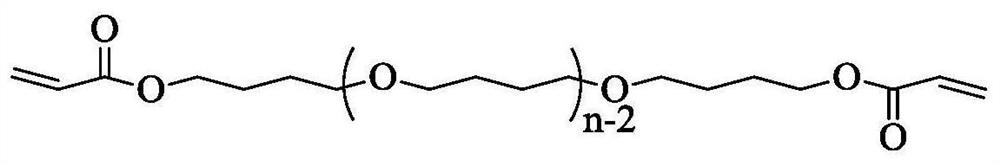

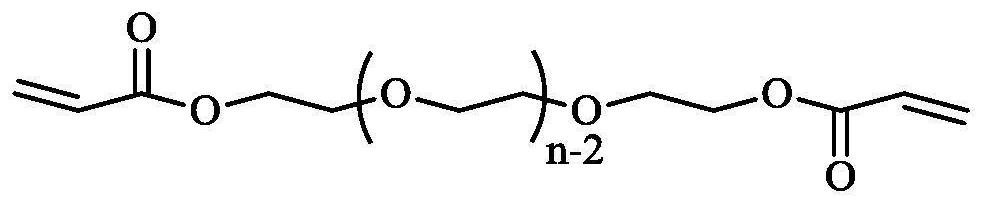

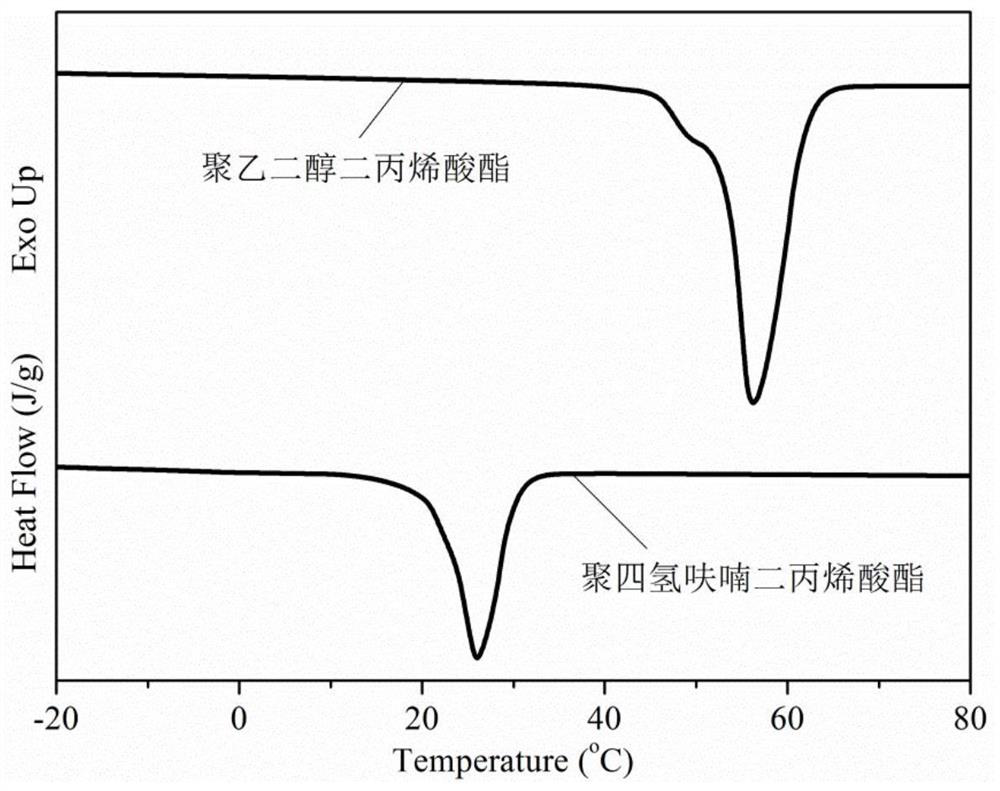

[0085] 331.0 mg of polytetrahydrofuran diacrylate, 220.4 mg of polyethylene glycol diacrylate, 45.8 mg of pentaerythritol tetra-3-mercaptopropionate, and 5.5 mg of benzoin dimethyl ether were dissolved in 1.1 ml of chloroform solution. After ultrasonically obtaining a uniform transparent precursor solution, inject the precursor solution into the transparent mold, remove air bubbles, and seal. Place the mold under a 365nm ultraviolet lamp for cross-linking and polymerization for 1.5 hours, then take out the fully cross-linked polymer from the mold and vacuum-dry it in a 40°C oven to constant weight to obtain a two-way reversible shape memory with human body temperature response and human body temperature, Water-responsive triple shape-memory polymer material.

[0086] The polytetrahydrofuran diacrylate used in this example has a molecular weight of 2900 g / mol and a melting point of 26.0 °C. The polyethylene glycol diacrylate used had a molecular weight of 4000 g / mol and a melt...

Embodiment 2

[0095] 275.4 mg of polytetrahydrofuran diacrylate, 274.9 mg of polyethylene glycol diacrylate, 43.9 mg of pentaerythritol tetra-3-mercaptopropionate, and 5.5 mg of benzoin dimethyl ether were dissolved in 1.1 ml of chloroform solution. After ultrasonically obtaining a uniform transparent precursor solution, inject the precursor solution into the transparent mold, remove air bubbles, and seal. Place the mold under a 365nm ultraviolet lamp for cross-linking polymerization for 1.5 hours, then take out the fully cross-linked polymer from the mold and vacuum-dry it in a 40°C oven to constant weight to obtain a two-way reversible shape memory with human body temperature response and human body temperature, Water-responsive triple shape memory polymer material. The material exhibits good two-way shape memory properties between -20 °C and 37 °C, with a reversible strain of 9.73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com