Shale gas fracturing and sand adding method

A gas pressure and shale technology, which is used in earth-moving drilling, data processing applications, wellbore/well components, etc., and can solve the problems of narrow fracture width, difficulty in sanding, and difficulty in ensuring the scale of proppant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

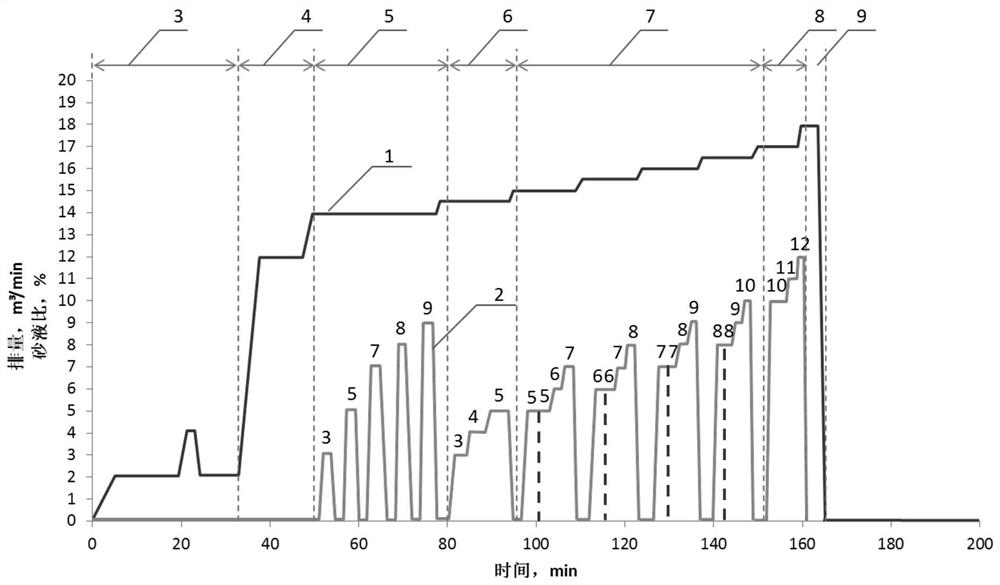

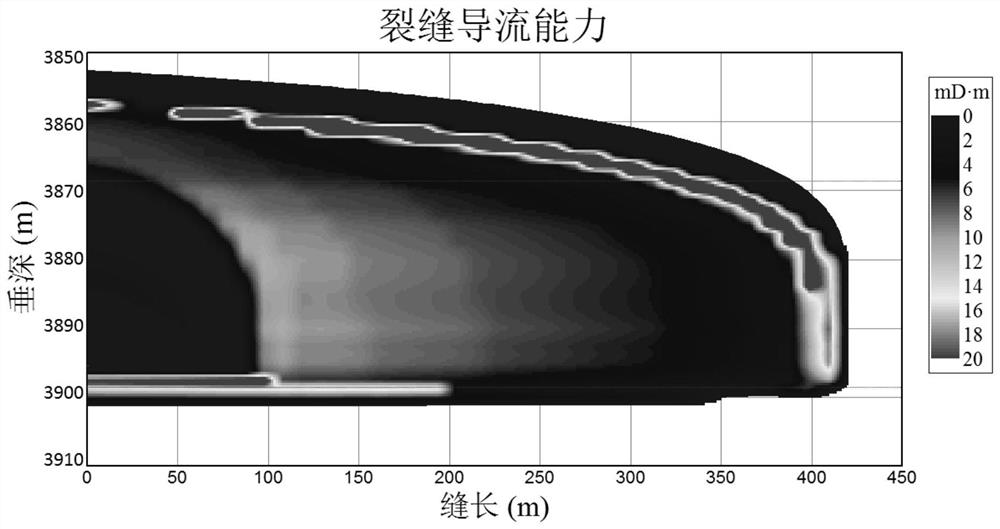

[0093]Well DJ-1 is a deep marine shale gas horizontal well. The target layer of the well is the Lower Silurian Longmaxi Formation-Upper Ordovician Wufeng Formation, with a vertical depth of 3910m in the middle of the target layer. The horizontal section of the well passes through the target layer with an average silica content of 54.5%, an average calcium content of 9.5%, and a brittleness index of 62%-65%; Young's modulus is 46GPa, Poisson's ratio is 0.21; the maximum horizontal principal stress is 96~118MPa, the minimum The horizontal principal stress is 75-93MPa, the absolute value of the two-dimensional horizontal stress difference is 8-24MPa, and the difference between the vertical stress and the minimum horizontal principal stress is 1.7-16.4MPa; imaging logging shows that the target layer is well developed. In general, the well’s target layer is buried deep, the rock strength is high, and the rock mechanical properties are different. It is difficult to predict rock cracking a...

Embodiment 2

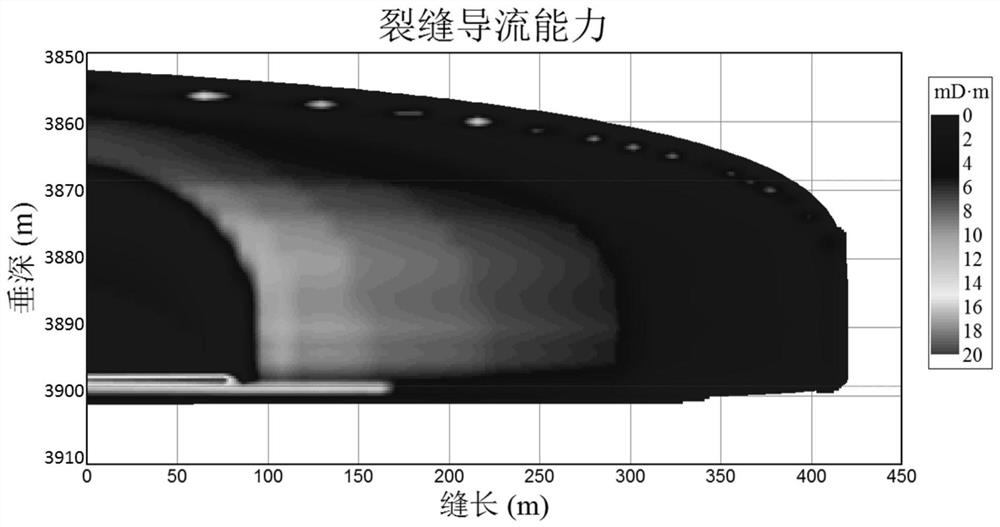

[0105]Well DY5 is a deep marine shale gas horizontal well. The target layer of the well is the Lower Silurian Longmaxi Formation-Upper Ordovician Wufeng Formation, with a vertical depth of 3701m in the middle of the target layer. The horizontal section of the well passes through the target layer with an average quartz content of 52.8%, an average carbonate content of 6.8%, an average shale content of 22.1%, an average Poisson's ratio of 0.22, a Young's modulus of 36.6 GPa, a brittleness index of 65%, and the difference in horizontal ground stress between the two directions. The coefficient is 0.165 and the compressibility index is 0.55. Imaging logging shows that the target layer has developed horizontal bedding, and there are high conduction fractures and high resistance fractures in some intervals. From the perspective of engineering geological parameters, the target layer of the well has a high brittleness index, a small difference in horizontal stress, and natural fractures in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com