Natural gas hydrate heat injection-replacement combined simulation mining device and method

A technology for simulating production and hydrates, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., which can solve the problems of low replacement efficiency and high cost of heat injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

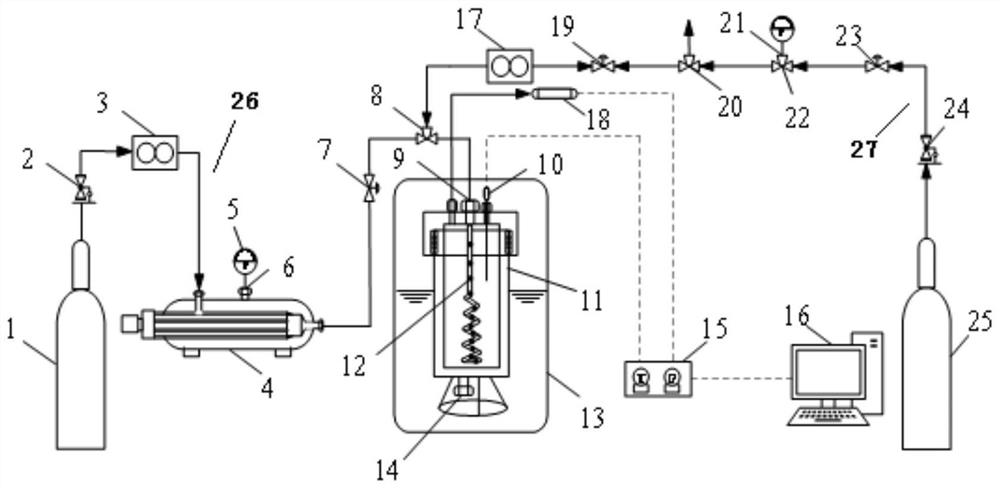

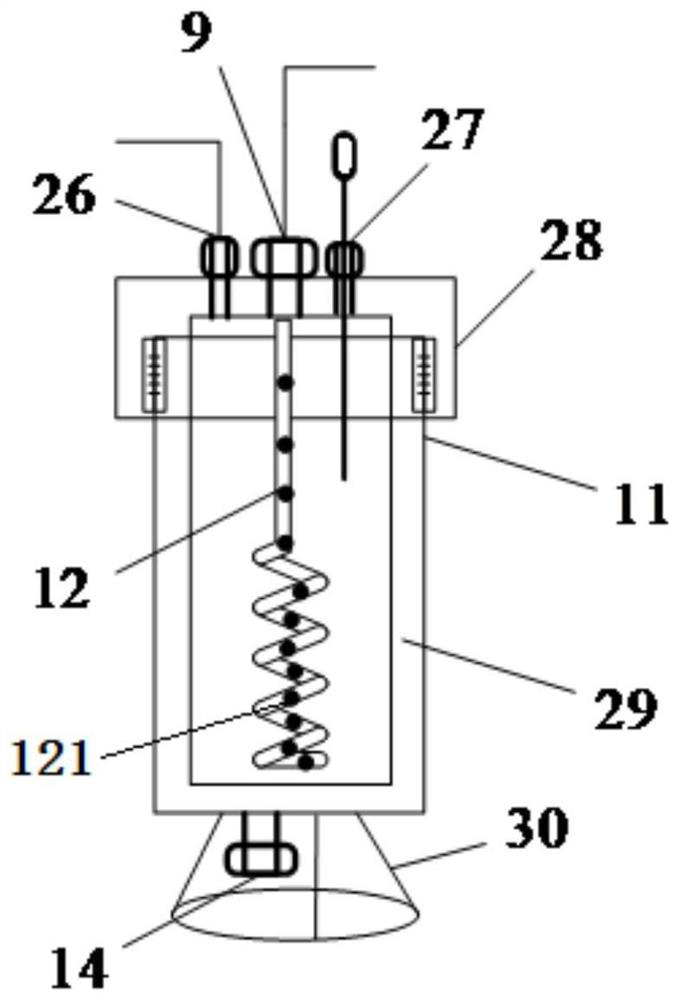

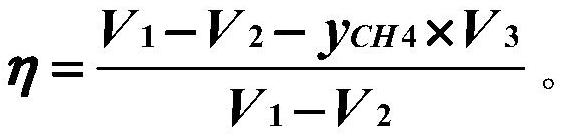

[0061] Such as figure 1 The experimental device for the combined simulation of natural gas hydrate heat injection-displacement production is shown, including the displacement gas (CO 2 / N 2 ) cylinder 1, CH 4 Gas cylinder 25, first gas flowmeter 3, wet gas flowmeter 17, air heater 4, constant temperature water tank 13, reaction kettle 11, data acquisition instrument 15 and computer 16; reaction kettle 11 and air heater 4, gas flowmeter 3. The replacement gas cylinders 1 are connected in sequence; the constant temperature water tank 13 is arranged outside the reactor 11; the CH 4 The gas cylinder 25 is connected with the wet gas flow meter 17 and the reaction kettle 11 in sequence. The reaction kettle 11 is as figure 2 As shown, it includes a kettle body 29, a kettle cover 28 arranged on the top of the kettle body 29, a gas inlet and outlet 9 on the kettle cover 28, a bracket 30 supporting the bottom of the kettle body 29, and a sand outlet 14 placed at the bottom of the k...

Embodiment 2

[0072] The device is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com