Connecting system and connecting method for prefabricated composite foundation and full-prefabricated shear wall

A prefabricated shear force and connection system technology, which is applied in the direction of basic structure engineering, walls, buildings, etc., can solve the problems of difficulty in positioning the reserved lapped steel bars for the foundation, self-heavy weight, and high precision requirements, and achieve high construction efficiency and light weight , good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

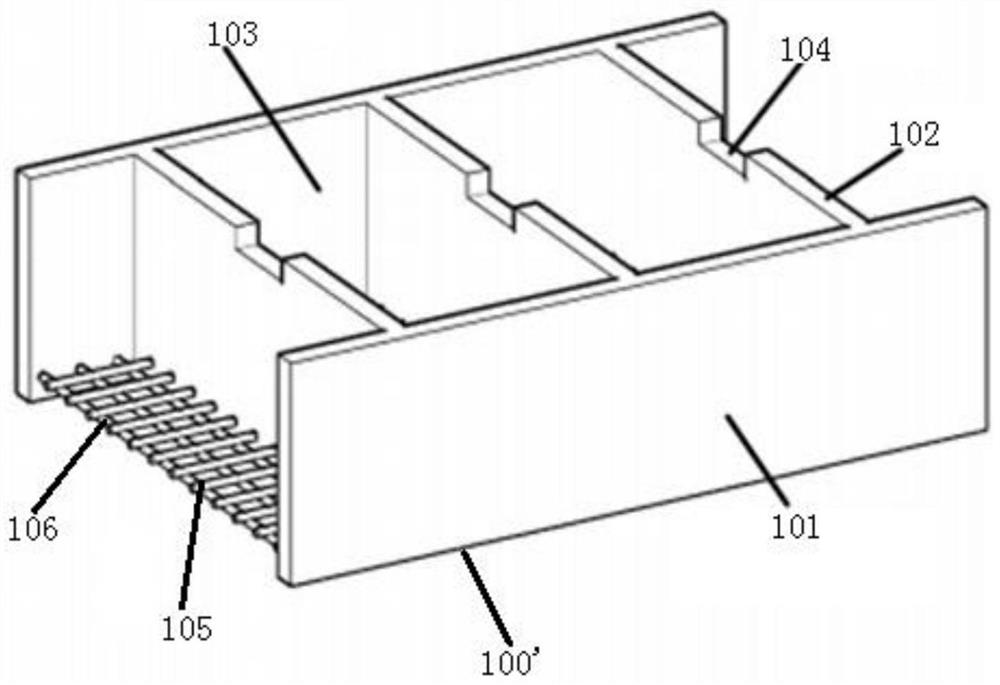

[0037] Embodiments of the present invention provide a connection system between prefabricated laminated foundations and fully prefabricated shear walls, such as Figure 1-5 As shown, it includes a prefabricated concrete composite foundation 100 and a fully prefabricated shear wall 200, wherein:

[0038] The precast concrete composite foundation 100 includes an outer wall panel 101 and at least one inner partition 102 arranged in the outer wall panel 101. The inner partition 102 divides the interior of the outer wall panel 101 into several cavities 103. Each inner partition A positioning groove 104 is formed on the top of the 102 .

[0039] The bottom of the fully prefabricated shear wall 200 is provided with reserved longitudinal reinforcement 201, the bottom edge of the fully prefabricated shear wall 200 is stuck in the positioning groove 104, the reserved longitudinal reinforcement 201 is inserted into the cavity 103, and concrete is poured in the cavity 103 , so that the p...

Embodiment 2

[0057] The embodiment of the present invention provides the connection method of the connection system between the prefabricated laminated foundation and the fully prefabricated shear wall described in embodiment 1, such as Figure 1-2 As shown, the connection methods include:

[0058] S1: hoisting and positioning the precast concrete composite foundation 100 on a flat ground.

[0059] The prefabricated concrete composite foundation is transported, hoisted and positioned after being prefabricated in the factory. Before the foundation is installed, the ground at the bottom of the prefabricated foundation should be ensured to be flat. Because the precast concrete composite foundation has a cavity, it can greatly reduce its own weight, which is beneficial to the transportation, installation and positioning of the precast concrete composite foundation, and has lower requirements for hoisting equipment, which is convenient for construction.

[0060] S2: Hoist the fully prefabricat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com