Rare earth adding control method for high-strength rare earth girder steel

A control method and rare earth technology, applied in the direction of manufacturing converters, etc., can solve the problems of complicated operation of rare earth wire feeding method, poor stability of rare earth addition, low yield, etc. The effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

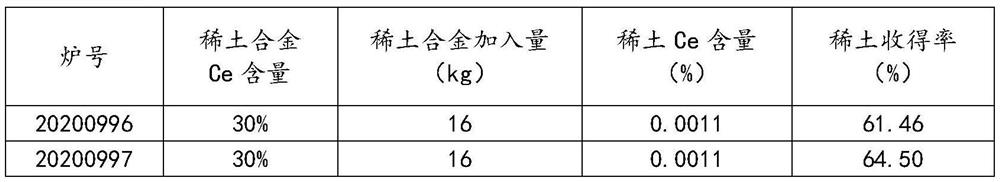

[0021] Example 1: Implementation case of adding rare earths to BT700L, a high-strength beam steel with rare earths

[0022] A method for controlling the addition of rare earth to high-strength rare earth girder steel, comprising:

[0023] After KR is treated by deep desulfurization process, the sulfur content of molten iron is 0.001%, which meets the requirements of molten iron. The carbon content at the end point of the converter is controlled above 0.03%, and the oxygen content at the end point is low, so as to avoid overoxidation of molten steel and reduce oxidative inclusions in molten steel. The end point temperature is controlled within the range of 1623°C to 1638°C.

[0024] The purpose of refining is mainly to desulfurize and deoxidize, remove inclusions in steel, and ensure the cleanliness of molten steel. The LF furnace quickly produces white slag, ensures the alkalinity of molten steel, and reduces the oxidation of slag, which is conducive to rapid deoxidation and...

Embodiment 2

[0030] Example 2: Rare earth high strength beam steel BT610L added rare earth implementation case

[0031] A method for controlling the addition of rare earth to high-strength rare earth girder steel, comprising:

[0032] After KR is treated by deep desulfurization process, the sulfur content of molten iron entering the furnace is within 0.002%, which meets the requirements of molten iron entering the furnace. The carbon content at the end point of the converter is controlled above 0.03%, and the oxygen content at the end point is low, so as to avoid overoxidation of molten steel and reduce oxidative inclusions in molten steel. The end point temperature is controlled within the range of 1631-1649°C.

[0033] The purpose of refining is mainly to desulfurize and deoxidize, remove inclusions in steel, and ensure the cleanliness of molten steel. The LF furnace quickly produces white slag, ensures the alkalinity of molten steel, and reduces the oxidation of slag, which is conduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com