System and method for co-producing coal gas and powdery active coke

A technology of activated coke and powder, applied in the field of efficient and clean utilization of coal, can solve the problems of increased energy consumption, low calorific value of pyrolysis gas, and low grade, and achieve high utilization rate, high calorific value, and high content of effective gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

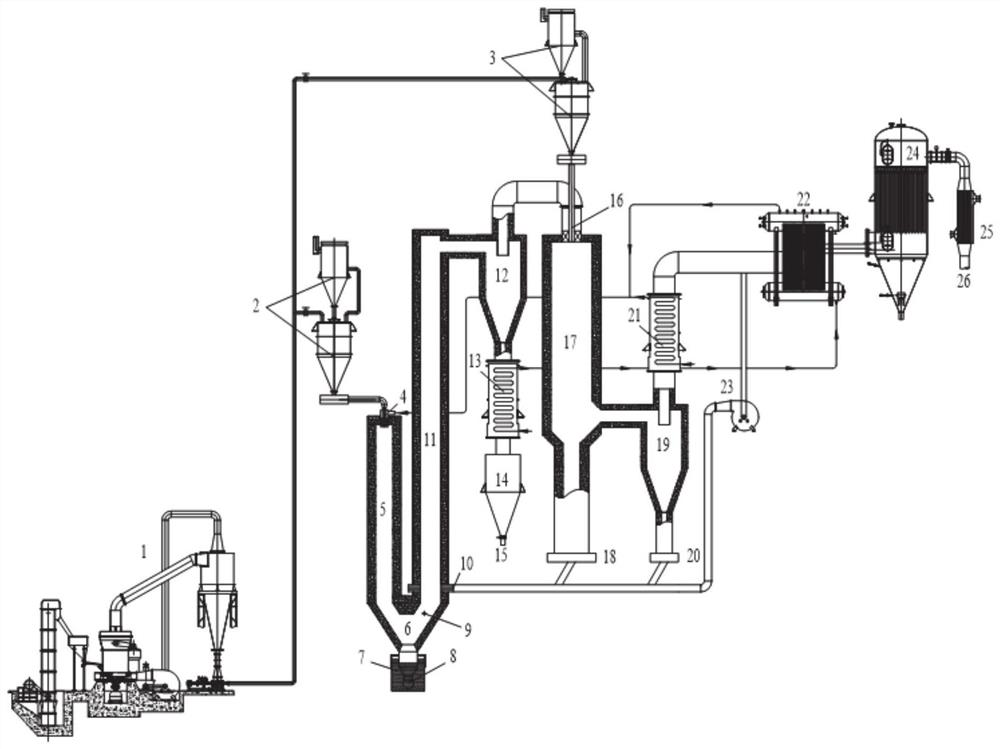

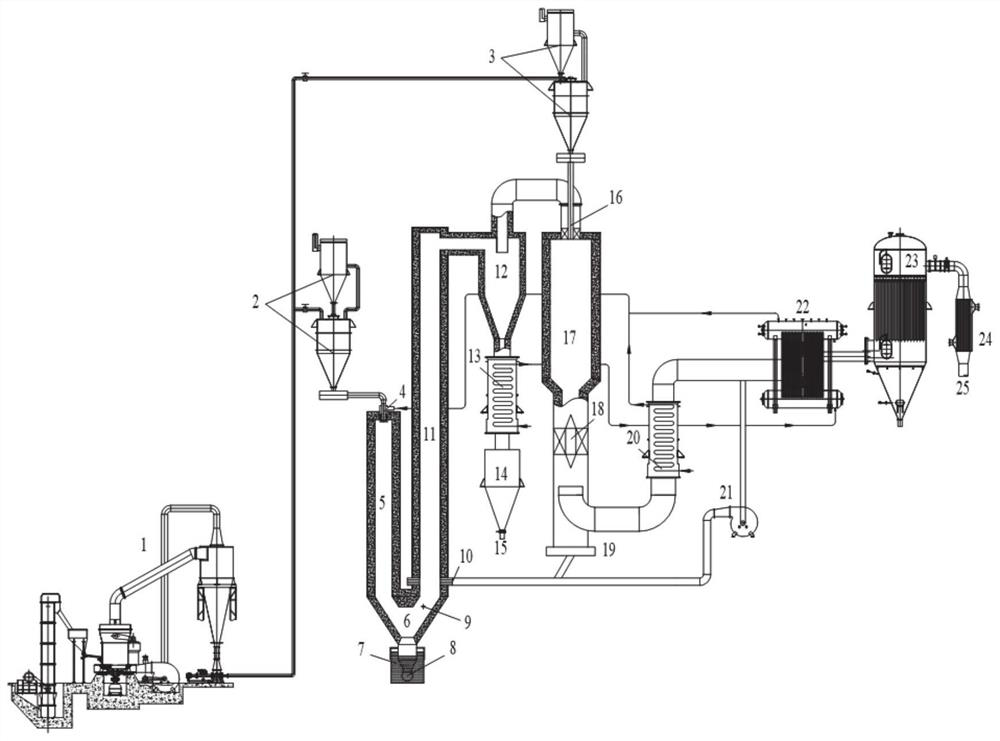

[0075] Coal powder (moisture content less than 15%, calorific value 5000kcal, average particle size 200 mesh) is gasified in a gasifier, the gasification agent is air and water vapor, the temperature of the gasification agent is 300-350 ° C, the gasification The melting time is 3-7s. The temperature of the generated gasification gas is 1350-1450°C;

[0076] The gasification gas is tempered by water / steam before entering the activation furnace, the temperature is reduced to 1100-1200°C, and the water vapor content is 20-40%;

[0077] Gasification gas and carbonized semi-coke are mixed up, the activation time is 3-10s, and the temperature of the activated gas is 800-1000°C;

[0078] After the powder coke cools down to 80°C, the water (80°C) in the powder coke cooler enters the waste heat boiler;

[0079] The coal gas enters the carbonization furnace and is carbonized with coal powder. The temperature of the gas at the inlet of the carbonization furnace is 800-1000°C, the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com