Injection molding machine and control method of injection molding machine

An injection molding machine and injection molding technology, applied in the control field of injection molding machines and injection molding machines, can solve problems such as adhesion and dirt, affecting product quality, and achieve the effects of increasing temperature, ensuring processing quality, and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

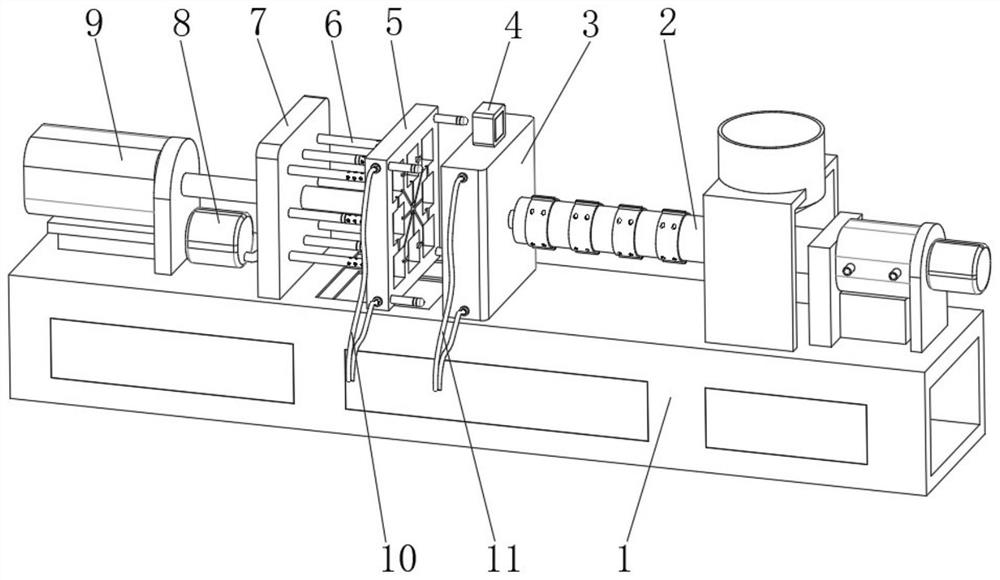

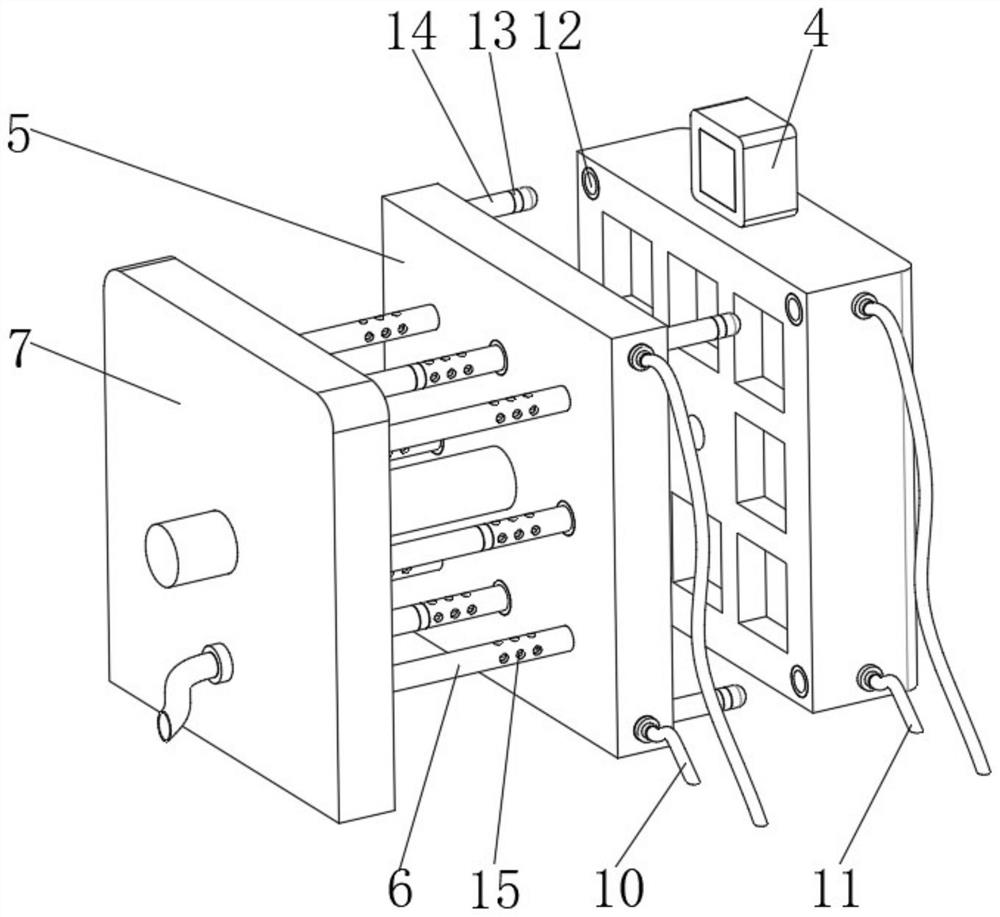

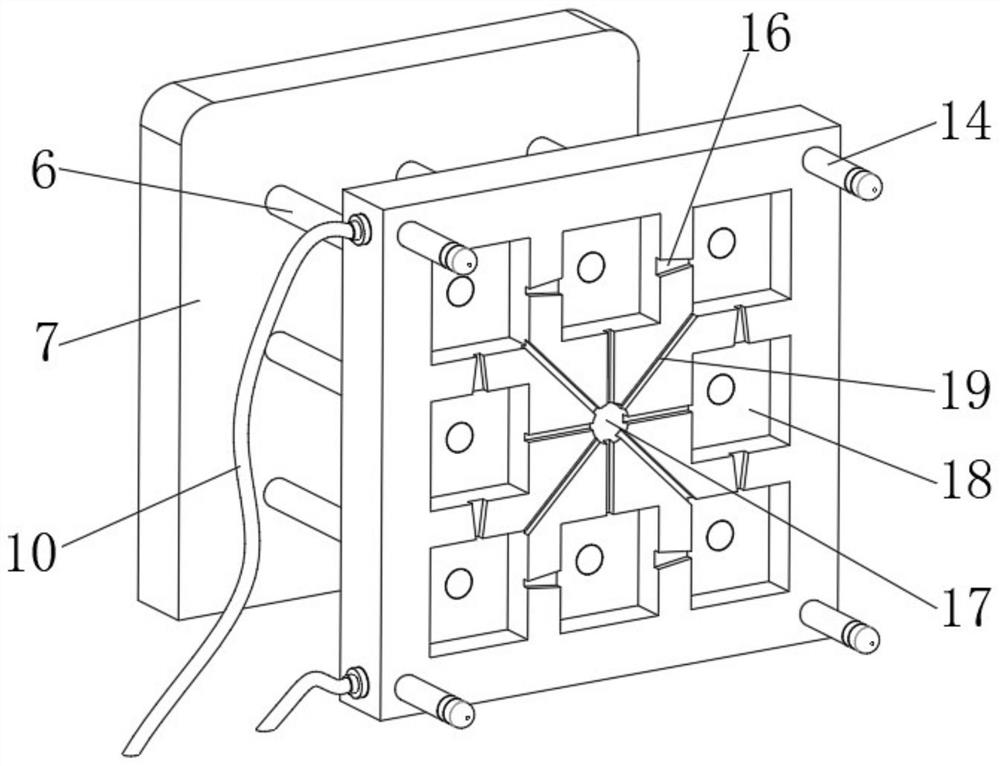

[0042] An injection molding machine such as Figure 1-7 As shown, it includes a workbench 1, the top outer wall of the workbench 1 is equipped with an injection molding mechanism 2 and a mold mechanism, the inside of the workbench 1 is provided with a control module, and the mold mechanism includes an injection molding movable mold 5 and an injection molding fixed mold 3, The inner wall of one side of the fixed injection mold 3 is connected to the output end of the injection mechanism 2, and the outer wall of the bottom of the fixed injection mold 3 is fixed to the outer wall of the top of the workbench 1 by screws, and the outer wall of the top of the workbench 1 is equipped with a servo cylinder 9 through a mounting frame. 1. The outer wall of the top is fixed with the ejector seat 7 by screws, and the output end of the servo cylinder 9 penetrates the ejector seat 7 and then is fixed to the outer wall of one side of the injection movable mold 5 by screws; the injection movabl...

Embodiment 2

[0052] A control method of the injection molding machine described in embodiment 1, such as Figure 1-7 shown, including the following steps:

[0053] S1: The injection molding mechanism 2 works to extrude the material into the core 18;

[0054] S2: During the extrusion process, the timer 4 is timed synchronously, and the electric temperature control liquid tank is kept warm through the first temperature control pipeline 10 and the second temperature control pipeline 11;

[0055] S3: After the injection molding is completed, the timer 4 counts to the first specified value, and the temperature of the electric temperature-controlled liquid tank is lowered through the first temperature-controlled pipeline 10 and the second temperature-controlled pipeline 11;

[0056] S4: After cooling down, the servo cylinder 9 works to control the injection movable mold 5 to retract, during which the hollow ejector rod 6 ejects the product;

[0057] S5: When the injection mold 5 is retracted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com