Novel enthalpy increasing pipe integrated machining method

A processing method and technology for increasing enthalpy tubes, applied in the field of increasing enthalpy tubes, can solve the problems of easy burrs, compressor damage, poor welding, etc. in machined sealing grooves, and achieve the effects of low cost, prevention of damage problems, and good verticality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

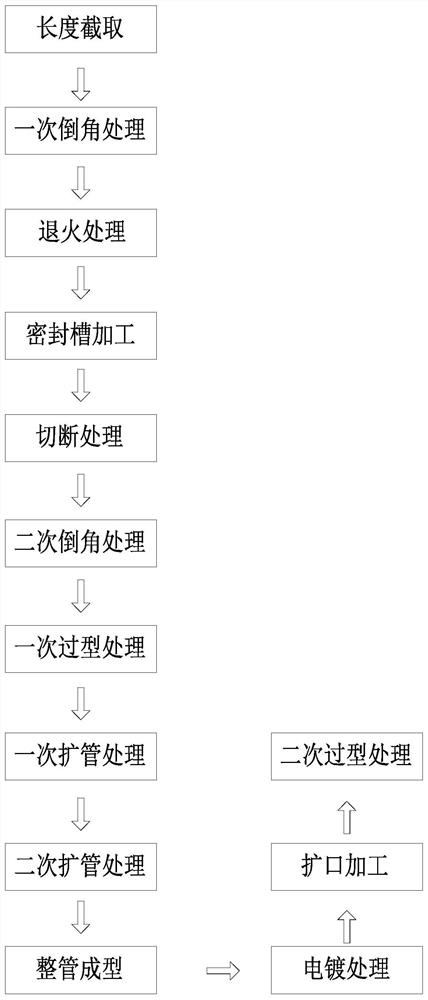

[0036] Such as Figure 1 to Figure 11 As shown, a novel enthalpy-increasing tube integrated processing method includes the following steps:

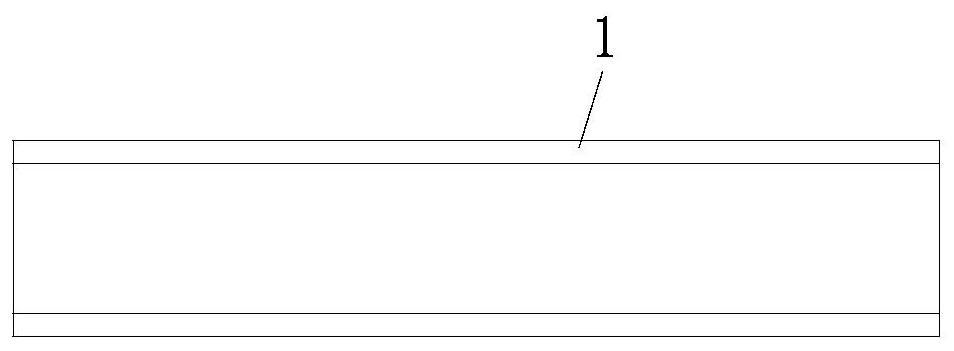

[0037] a. Cutting the length, cutting the formed seamless steel pipe into a straight round pipe of the required length according to production needs. The purpose of using seamless steel pipe is that it has high hardness and stronger compression resistance than other commonly used metal round pipes;

[0038] b, one-time chamfering processing, the two ports formed by the straight round pipe 1 cut out in step a are chamfered; the burrs produced by the ports when the seamless steel pipe is cut are removed by one-time chamfering;

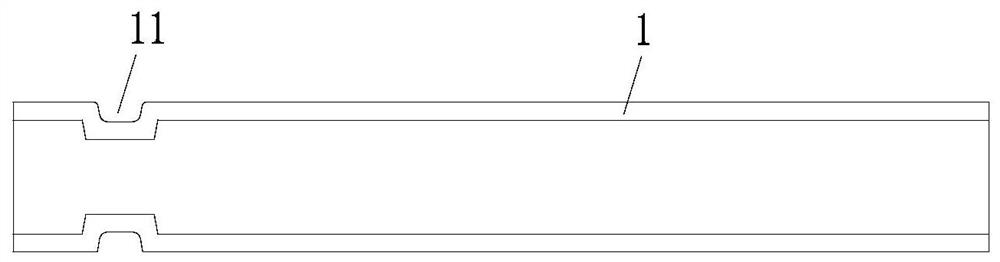

[0039] c, seal groove processing, carry out spinning processing to one end of the straight round pipe 1 of step b by spinning machine, form the ring-shaped seal groove 11, described seal gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com