Instant stirring and spraying device for dust suppressant for railway coal transportation

A technology of spraying device and stirring device, which is applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of inability to stir and spray dust suppressant, time-consuming, inconvenient, etc., reduce labor intensity and labor cost, simplify operation process, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

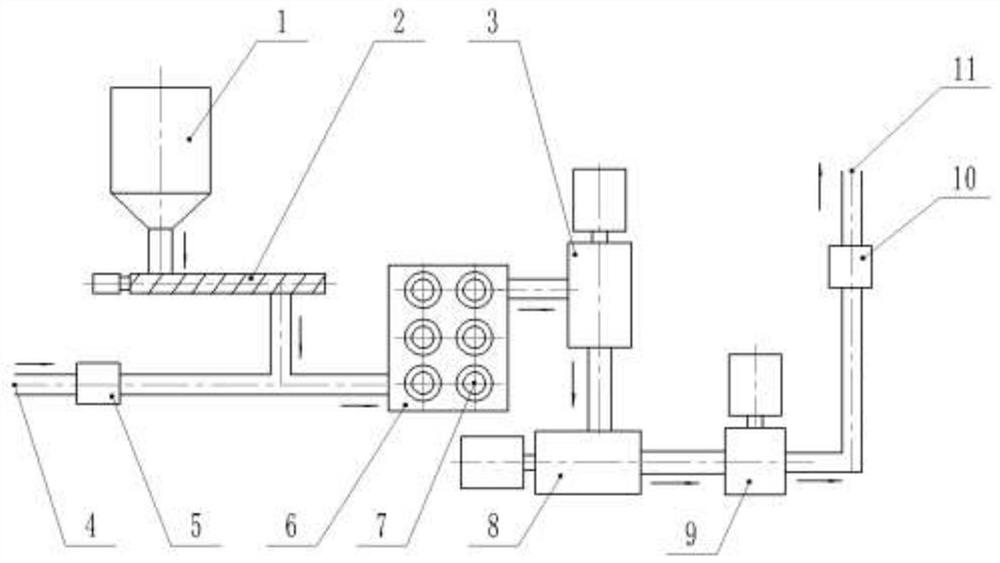

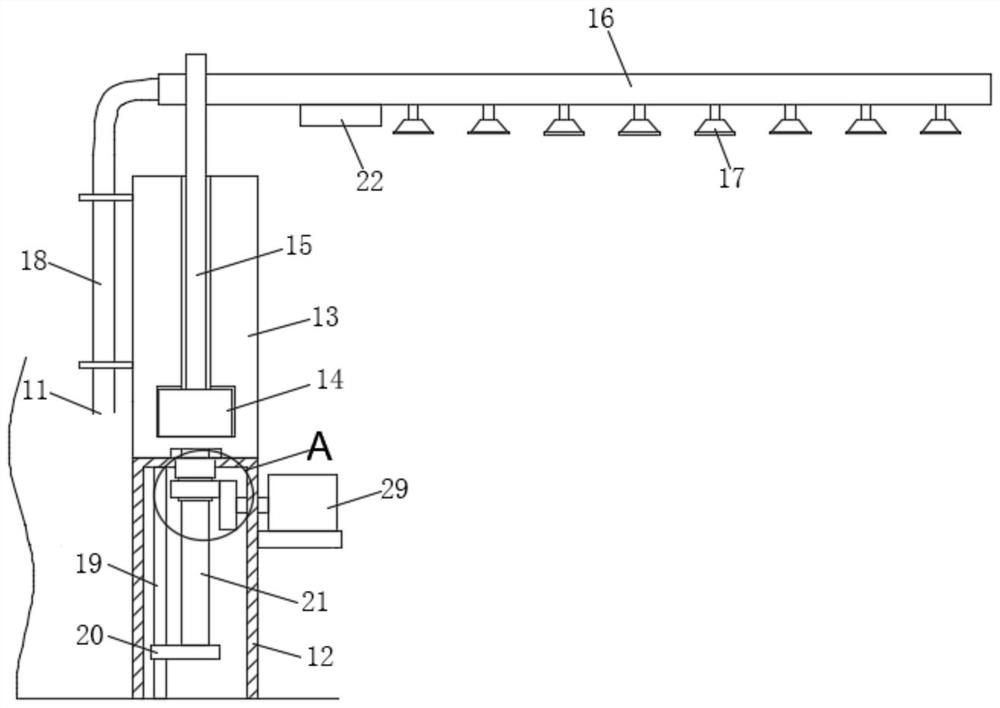

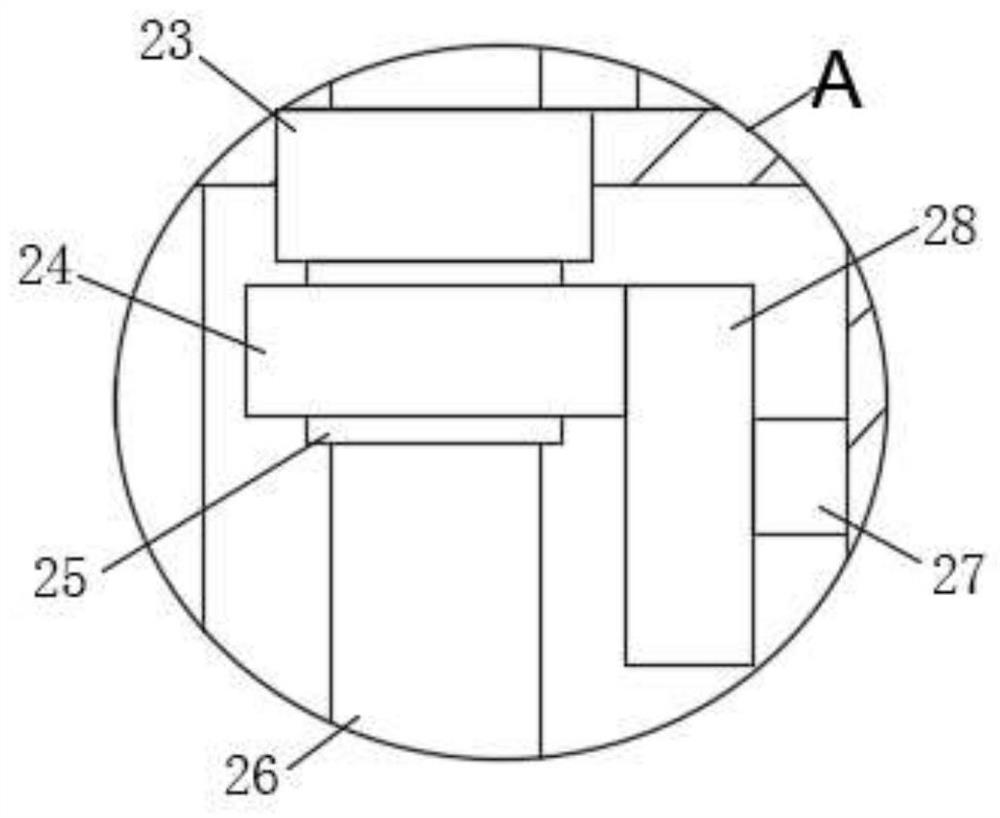

[0019] see Figure 1-3 It is the real-time mixing and spraying device for dust suppression agent for railway coal transportation shown in the present invention, including: powder silo 1, screw conveyor 2, first homogeneous pump 3, water inlet 4, first electromagnetic flow valve 5, stirring device 6 , mixing blade 7, second homogeneous pump 8, plunger water pump 9, second electromagnetic flow valve 10, sprinkler interface 11, column 12, connecting seat 13, second motor 14, rotating rod 15, liquid spray rod 16, Nozzle 17, feeding pipe 18, limit rod 19, limit plate 20, lifting mechanism 21, infrared velocimeter 22, bearing 23, first bevel gear 24, connecting pipe 25, movable column 26, rotating shaft 27, second Bevel gear 28, second motor 29, remote terminal equipment (not shown in the figure). in:

[0020] The powder silo 1 is arranged on the device for receiving and storing the powder so as to transfer the powder to the screw conveyor 2; the screw conveyor 2 is arranged at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com