Fe-coated SiO2 catalyst as well as preparation method and application thereof

A catalyst, sodium hydroxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve unstable electrode catalytic performance, low output voltage, device The problem of high cost is to achieve the effect of high cathode electron transfer rate, low operating cost and high electrocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

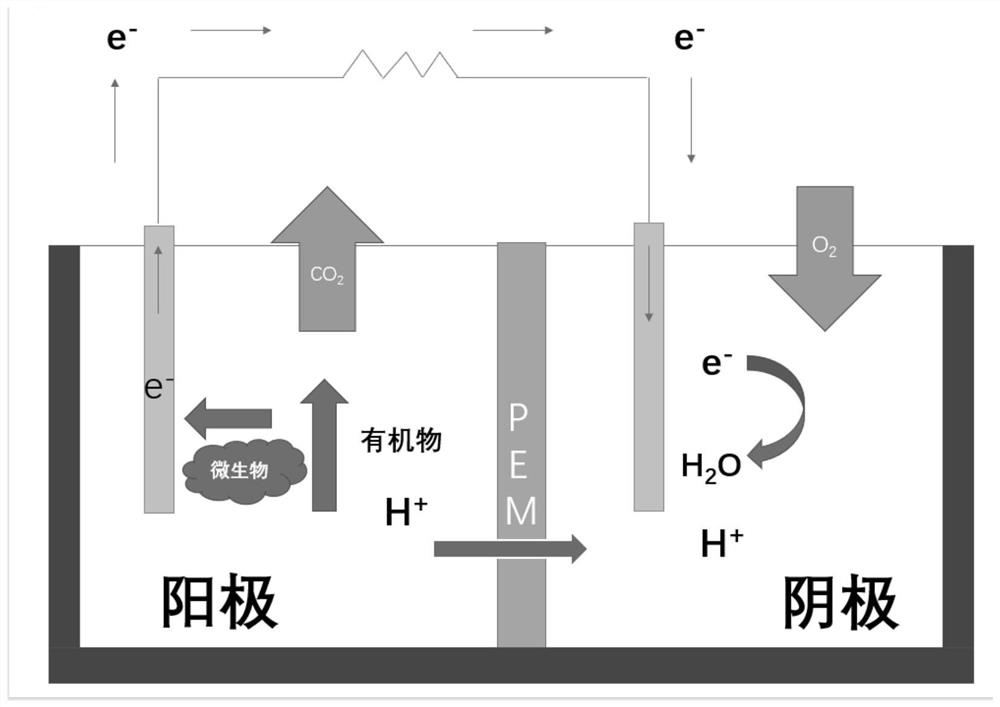

[0033] An embodiment of the Fe@SiO2 catalyst of the present invention, the microbial fuel cell reactor described in this embodiment is as figure 1 As shown, the preparation process of the Fe@SiO2 catalyst described in this embodiment includes the following steps:

[0034] (1) Stir 2-aminoterephthalic acid, ferric chloride hexahydrate and N,N-dimethylformamide at 20-30°C to obtain the first mixed solution; The mass ratio of formic acid, ferric chloride hexahydrate and N, N-dimethylformamide is: 2-aminoterephthalic acid: ferric chloride hexahydrate: N, N-dimethylformamide = 1:1: 272;

[0035] (2) keeping the first mixed solution in step (1) at 140° C. for 12 hours to obtain a dark brown mixture;

[0036] (3) Adding N,N-dimethylformamide to the dark brown mixture in step (2), stirring and washing, centrifugal filtration, and vacuum drying at 70° C. for 12 hours to obtain the first solid object;

[0037] (4) uniformly mixing the first solid object obtained in step (3) with sodi...

Embodiment 2

[0041] An embodiment of the Fe@SiO2 catalyst of the present invention, the microbial fuel cell reactor described in this embodiment is as figure 1 As shown, the preparation process of the Fe@SiO2 catalyst described in this embodiment includes the following steps:

[0042] (1) Stir 2-aminoterephthalic acid, ferric chloride hexahydrate and N,N-dimethylformamide at 20-30°C to obtain the first mixed solution; The mass ratio of formic acid, ferric chloride hexahydrate and N, N-dimethylformamide is: 2-aminoterephthalic acid: ferric chloride hexahydrate: N, N-dimethylformamide = 1: 1.49: 272.13;

[0043] (2) keeping the first mixed solution in step (1) at 150° C. for 18 hours to obtain a dark brown mixture;

[0044] (3) Adding N,N-dimethylformamide to the dark brown mixture in step (2), stirring and washing, after centrifugal filtration, vacuum drying at 80° C. for 18 hours to obtain the first solid object;

[0045](4) uniformly mixing the first solid object obtained in step (3) w...

Embodiment 3

[0049] An embodiment of the Fe@SiO2 catalyst of the present invention, the microbial fuel cell reactor described in this embodiment is as figure 1 As shown, the preparation process of the Fe@SiO2 catalyst described in this embodiment includes the following steps:

[0050] (1) Stir 2-aminoterephthalic acid, ferric chloride hexahydrate and N,N-dimethylformamide at 20-30°C to obtain the first mixed solution; The mass ratio of formic acid, ferric chloride hexahydrate and N, N-dimethylformamide is: 2-aminoterephthalic acid: ferric chloride hexahydrate: N, N-dimethylformamide = 1:2: 273;

[0051] (2) keeping the first mixed solution in step (1) at 160° C. for 24 hours to obtain a dark brown mixture;

[0052] (3) adding N,N-dimethylformamide to the dark brown mixture in step (2), stirring and washing, centrifuging, and drying at 90° C. for 24 hours to obtain the first solid object;

[0053] (4) uniformly mixing the first solid object obtained in step (3) with sodium hydroxide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com