Full-automatic intelligent sample weighing instrument and use method thereof

A sample weighing instrument and fully automatic technology, applied in the direction of instruments, weighing, and weighing equipment for materials with special properties/forms, etc., can solve problems such as high labor intensity, cross-contamination of samples, difficulty in continuous production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

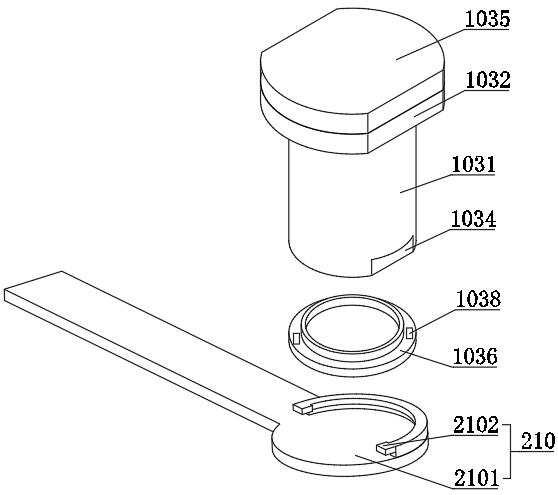

[0057] The full-automatic intelligent sample weighing instrument comprises a sampling section for grabbing a storage tank 103 filled with a sample and dropping the storage tank 103 into a vibrating sample section; Vibrating the sample storage tank 103 to realize the vibrating sample section of sample delivery; the sample weighing section located below the vibration sample section and carrying out real-time weighing to the sample vibrated out of the sample storage tank 103; and respectively connected with the sampling section, the The sample vibrating part is connected to the control part of the sample weighing part.

[0058] The sampling part includes a first robot body 101 , a first robot gripper 102 , a sample storage tank 103 , a storage tank storage plate 104 , and a storage tank storage hole 105 . The sample storage tank 103 includes a tank body 1031, a tank body limit sleeve and an outer eaves 1032, a sample outlet hole 1033, a blocking plate moving and releasing limit g...

Embodiment 2

[0092] How to use the fully automatic intelligent weighing instrument, the specific steps are as follows:

[0093] 1. Turn on the commercial power of the instrument, turn on the computer, and the screen displays the working interface: reset→sampling→vibrate and weigh samples→collect samples→reset.

[0094] 2. Click "Reset", the instrument enters the "Reset" self-test procedure.

[0095] At this time, the first robot body 101 and the first robot gripper 102 are in the original position; the electric lifting platform 202 is in the original position near the bottom of the support column 201; the vibrator 208 is in the closed state; the electric clamping mechanism 209 is in the loose state; The electric fork hand 210 is in the original position away from the storage tank cover hole 207; the stepper motor 211 is in the standby working state; the electronic balance 301 is in the standby working state; the second robot body 401 and the second robot gripper 402 are in the in situ.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com