Organic fiber composite repairing method for high-steep slope high-strength structure

A high-steep slope and organic fiber technology, which is applied in the field of mine ecological restoration, water and soil conservation in rivers, and slope greening, can solve the problems of less soil in the matrix layer, instability, and difficult construction, and achieve stable slope structure and layered clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

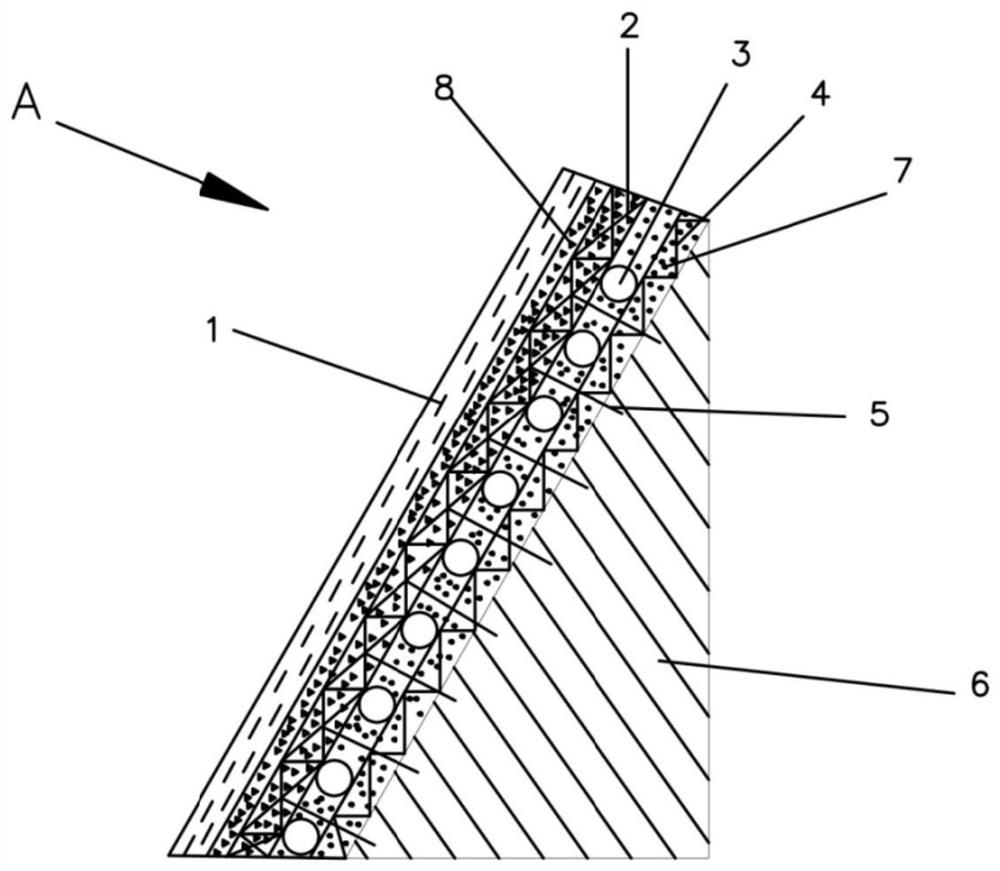

[0020] According to the high-strength structure organic fiber composite repair method for high and steep slopes proposed by the present invention, the schematic diagram of the slope body with wire mesh formed after the construction is as follows figure 1 As shown, the method includes the following steps:

[0021] (1) the slope of the slope body 6 of the high and steep slope is trimmed, and the slope debris and dangerous stones are cleaned up to keep the slope smooth;

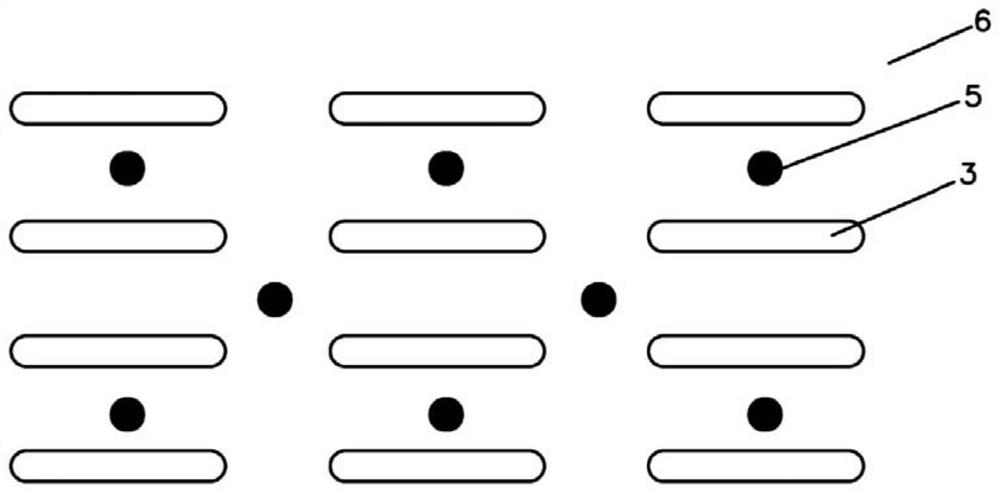

[0022] (2) On the slope of the slope body 6, drive the anchor rod 5, the lower end of the anchor rod 5 goes deep into the slope of the slope body 6, and the upper end of the anchor rod 5 stretches out from the slope of the slope body 6 to a certain height, and the anchor rod 5 The average density on the slope is greater than 100 per square meter;

[0023] (3) Lay bottom net 4 on the slope of slope body 6, anchor bar 5 stretches out from bottom net 4, make bottom net 4 be close to the slope of slope body 6, spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com