Waterproof and oil-proof process method for treating polyurethane fiber by adopting fluorooctylsulfonamide

A technology of fluorooctane sulfonamide and perfluorooctane sulfonamide, which is applied in the application field of polyurethane fiber treatment, can solve the problems of difficult cleaning, reduced usability, dirty surface, etc., and achieves waterproof and oil-proof performance, good sterilization, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

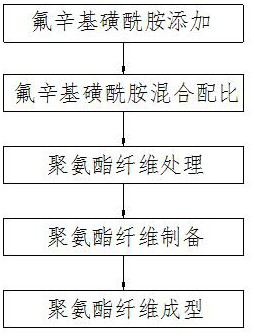

Image

Examples

Embodiment 1

[0024] A process for treating polyurethane fibers with fluorooctyl sulfonamide for waterproofing and oil repellency, said process comprising the steps of:

[0025] (1) Add fluorooctane sulfonamide, select N-ethyl perfluorooctane sulfonamide and FC-9--N-ethyl perfluorooctane sulfonamide for standby, heat and melt at a temperature of 100-200°C , and keep warm for fluorooctane sulfonamide for later use;

[0026] (2) The mixing ratio of fluorooctyl sulfonamide, the ratio of fluorooctyl sulfonamide in the molten state in step (1), select N-ethyl perfluorooctane sulfonamide and FC-9--N-ethyl The proportion of perfluorooctane sulfonamide is 2:1. Mix the obtained fluorooctane sulfonamide to obtain a mixture of fluorooctane sulfonamide. Separately prepare N-ethyl perfluorooctane sulfonamide and add the ratio Mix it with the alkyl hydrophobic group of 5:1 to prepare a hydrophobic intermediate agent, and keep it warm in a molten state with the fluorooctyl sulfonamide mixture for separat...

Embodiment 2

[0041] A process for treating polyurethane fibers with fluorooctyl sulfonamide for waterproofing and oil repellency, said process comprising the steps of:

[0042] (1) Add fluorooctane sulfonamide, select N-ethyl perfluorooctane sulfonamide and FC-9--N-ethyl perfluorooctane sulfonamide for standby, heat and melt at a temperature of 100-200°C , and keep warm for fluorooctane sulfonamide for later use;

[0043](2) The mixing ratio of fluorooctyl sulfonamide, the ratio of fluorooctyl sulfonamide in the molten state in step (1), select N-ethyl perfluorooctane sulfonamide and FC-9--N-ethyl The proportion of perfluorooctane sulfonamide is 2:1. Mix the obtained fluorooctane sulfonamide to obtain a mixture of fluorooctane sulfonamide. Separately prepare N-ethyl perfluorooctane sulfonamide and add the ratio Mix it with the alkyl hydrophobic group of 5:1 to prepare a hydrophobic intermediate agent, and keep it warm in a molten state with the fluorooctyl sulfonamide mixture for separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com