A kind of processing method of copper anode slime copper separation liquid

A technology of copper anode slime and treatment method, which is applied to the improvement of process efficiency, instruments, optics, etc., can solve problems such as complex process, low metal recovery rate, and large environmental hazards, and achieve avoidance of cyclic accumulation, low copper-arsenic ratio, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

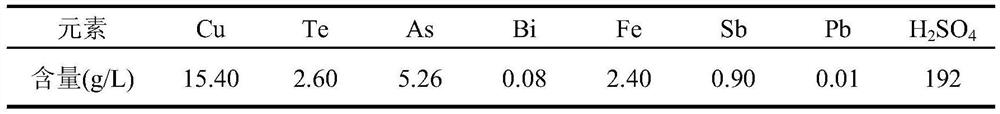

[0048] A corporate copper anode pressure leaching is shown in a copper solution, and its main chemical composition is shown in Table 1.

[0049] Table 1 Raw material ingredient

[0050]

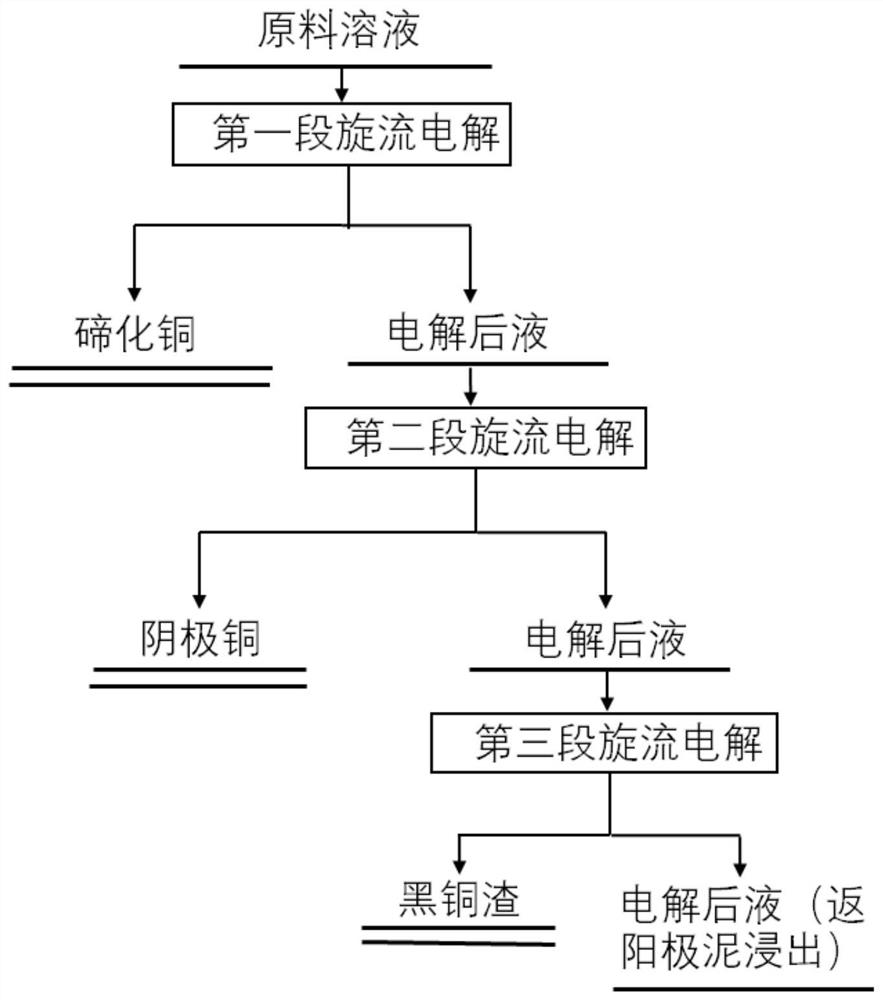

[0051] The treatment method of copper anode mud copper fluid according to the present invention is used to treat the discharge liquid, and the process flow chart is figure 1 As shown, including the following steps:

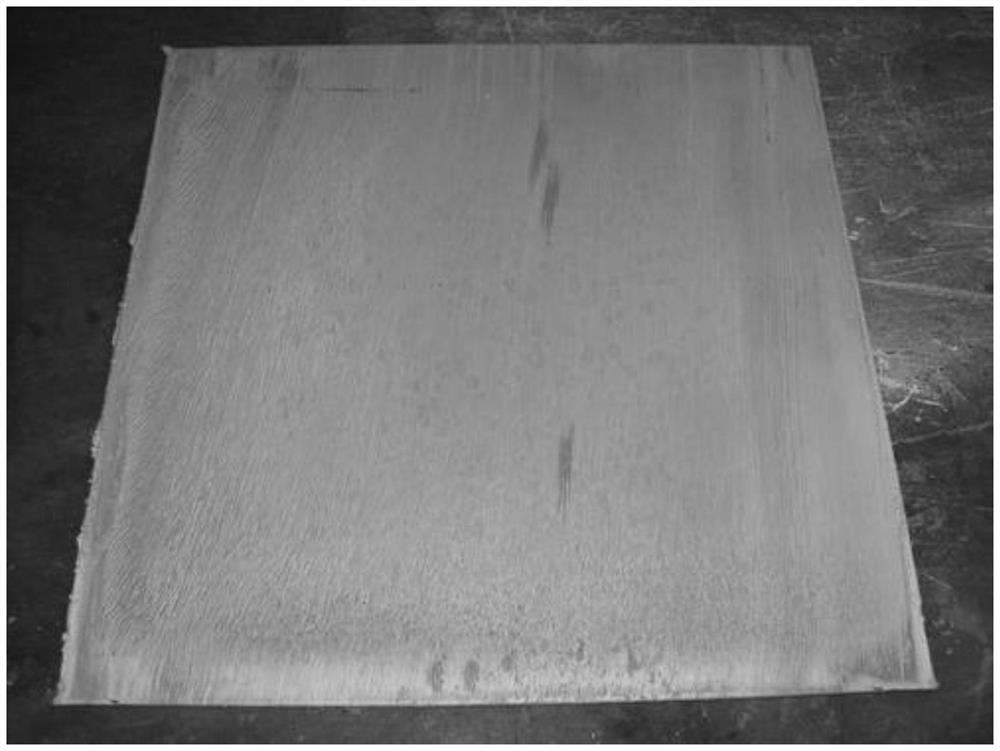

[0052] (1) Add 2 L of volume copper solution to a swirling electrolytic storage tank, and disposes the electric heating sleeve target temperature of 25 ° C, opening the magnetic drive cycle pump for electrolyte circulation, and adjusts the circulating flow rate of the electrolyte to 600 l / h. When the solution is cycled, there is no obvious bubble, turn on the power, control the current density bit 1500A / m. 2 Perform the first electrolysis. When the concentration of the orecty is reduced to 0.08 g / L to stop the electrolysis, the catholysis residue in the cathode collector is r...

Embodiment 2

[0062] A high-mixed copper fluid is shown in Table 4.

[0063] Table 4 Raw material ingredient

[0064]

[0065] The disconnect solution is treated with the treatment method of the copper anode mud copper fluid of the present invention, including the steps of:

[0066] (1) Add 2 L of volume copper solution to a swirling electrolytic storage tank, and provide an electric heating sleeve target temperature of 25 ° C to turn on the magnetic drive cycle pump for electrolyte cycle, and adjust the circulating flow rate of the circulating flowmeter adjusted electrolyte. 600L / h. When the solution is cycled, there is no obvious bubble, turn on the power supply, control the current density 1600A / m. 2 Perform the first electrolysis. When the concentration of the orecty is reduced to about 0.05 g / L to stop the electrolysis, the catholysis residue in the cathode collector is removed, and the recovery rate of the entire process of 199.1%, and the content of the content of the lysyl tellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com